Auxiliary spherical tank brace moving device

A technology of auxiliary movement and pillars, which is applied in the direction of furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve the problems of inability to guarantee the distance of pillars, the influence of the weld strength of the pillar bottom plate, and the same, and achieve the effect of meeting requirements, fast installation and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with specific embodiment, the present invention is further described:

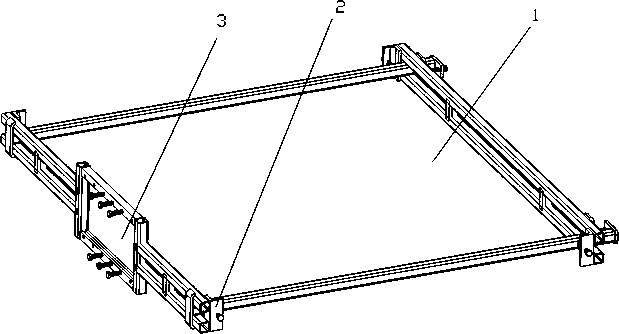

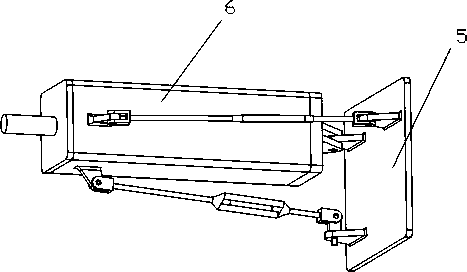

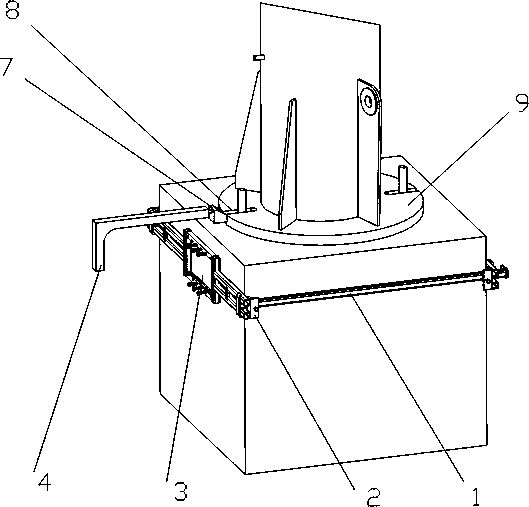

[0020] Such as Figure 1 to Figure 4 The auxiliary mobile device for the pillar of the spherical tank shown includes a traction mechanism, a fixed support and a movement mechanism; wherein the fixed support includes a rectangular frame 1, and any two sides of the rectangular frame 1 can slide on the other two sides to carry out The size of the frame is adjusted, and a fastening mechanism 2 and a platform 3 for installing a moving mechanism are installed on the rectangular frame 1; the traction mechanism is an L-shaped traction arm 4 with an opening downward, one end of which is connected to the support of the spherical tank The bottom plate 9 is connected, and the other end is connected to the motion mechanism; the motion mechanism includes a base 5 installed on the platform, a hydraulic jack 6 is installed on the base 5, and the piston of the hydraulic jack 6 supports the tract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com