An automatic moving system for heat treatment pillars of spherical tanks

An automatic moving and pillar technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of inability to guarantee the distance between pillars, the influence of the strength of the welding seam of the pillar bottom plate, and the same, and achieve the effect of fast installation, precise control and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with specific embodiment, the present invention is further described:

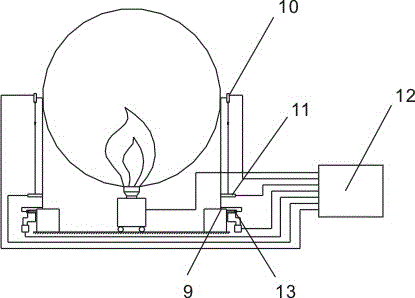

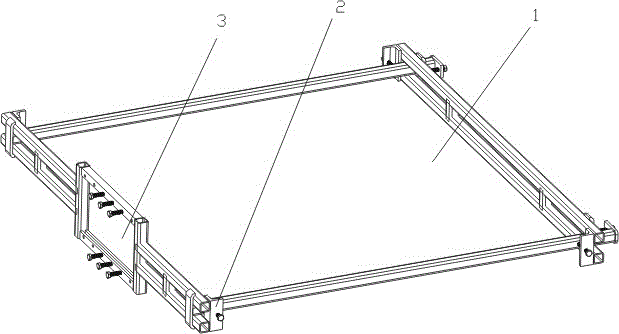

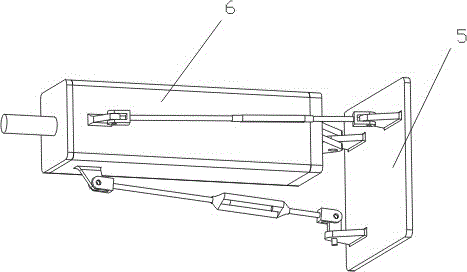

[0021] Such as Figure 1 to Figure 5 A spherical tank heat treatment pillar automatic moving system shown includes a signal transmitting and receiving device, a pillar auxiliary moving device 13, and a system control device; the signal transmitting and receiving device includes a signal transmitter 10 and a signal receiver 11, and the signal transmitter 10 Both the signal receiver and the signal receiver 11 have a magnetic base, which is directly adsorbed on the outside of the pillar of the spherical tank; the system control device 12 is a micro PC, which is connected and controlled with the signal transmitting and receiving device and the pillar auxiliary moving device 13 respectively; the pillar auxiliary The mobile device 13 is installed at the bottom plate 9 of the pillar of the spherical tank, and includes a traction mechanism, a fixed support and a movement mechanism; wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com