A kind of preparation method of 800mpa level heat treatment wheel

An 800mpa, wheel technology, applied in heat treatment equipment, heat treatment furnaces, manufacturing tools, etc., can solve problems such as weak resistance to deformation, achieve the effect of reducing the weight of a single wheel, benefiting mechanical properties, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] A method for preparing an 800MPa grade heat-treated wheel, comprising the following steps:

[0036] Step 1) select steel, the chemical composition mass percentage composition of steel is: C 0.19, Si 1.13, Mn 1.76, Al0.04, P 0.018, surplus is Fe and unavoidable impurity; The tensile strength of described steel is 670MPa, the yield strength is 450MPa;

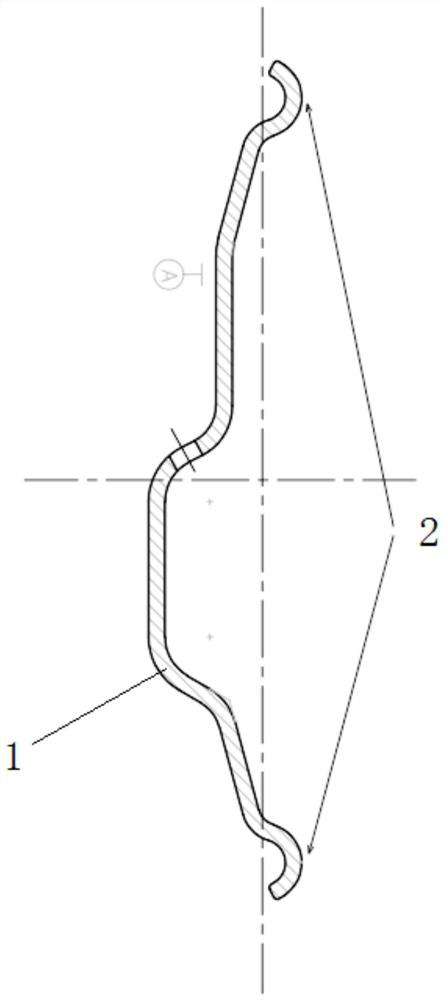

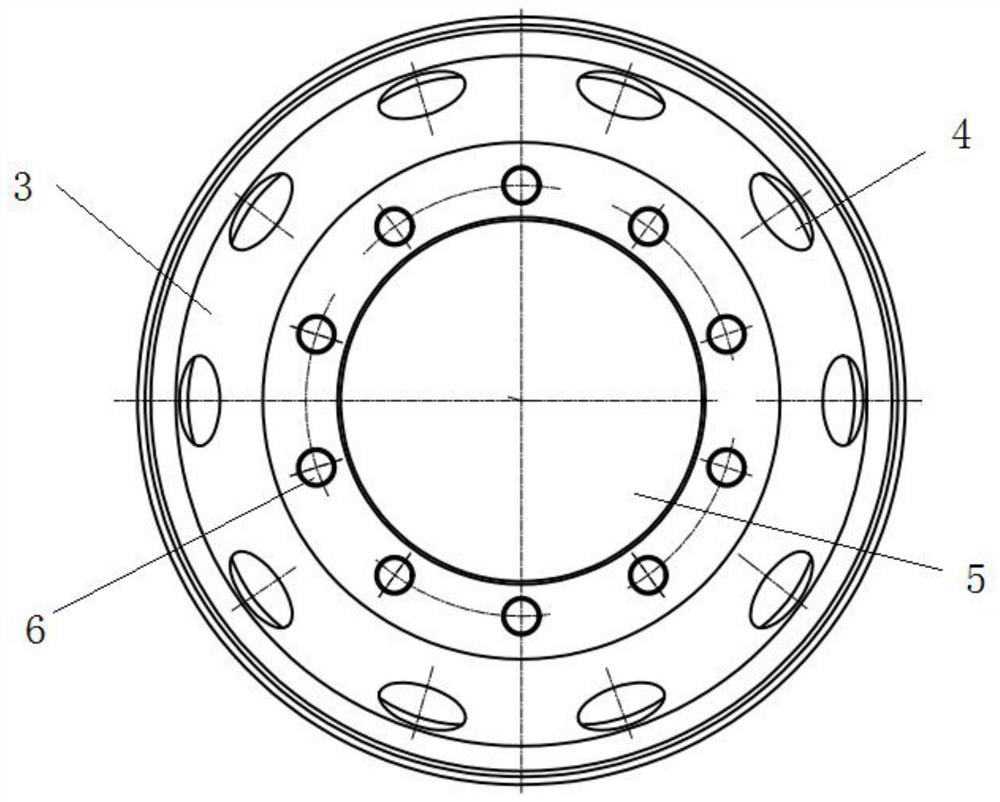

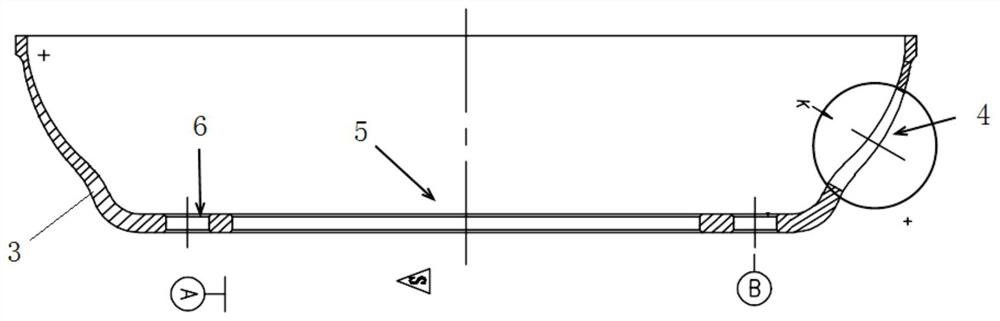

[0037] Step 2) as in Figure 1-4 As shown, the wheel spoke 3 with a qualified size is manufactured by using a conventional production process with steel, the thickness of the spoke sheet is 9 mm, and the thickness of the four air holes after processing is 5.5 mm, and the wheel rim 1 with a qualified size is manufactured with a conventional production process with steel. After the flash butt welding process, the weld seam is annealed, and the expansion amount of the expansion process is 25mm; the wheel spoke 3 and the wheel rim 1 are made of a qualified wheel by synthetic welding process, and the welding wire composition i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com