Diffusion welding method for double alloy structure of plunger hydraulic pump motor rotor

A motor rotor and diffusion welding technology, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of large deviation of copper wall thickness of plunger holes and deformation of welding test pieces, so as to broaden application ideas and improve stability performance, improve the effect of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

[0022] Example. The method for diffusion welding of the double alloy structure of the rotor of the plunger hydraulic pump motor is characterized in that it is carried out according to the following steps:

[0023] ① Pre-processing the dimensions of the parts to be welded;

[0024] ②Sequentially carry out gasoline immersion ultrasonic treatment, drying, pickling ultrasonic treatment, water rinsing, absolute ethanol immersion ultrasonic treatment, and drying;

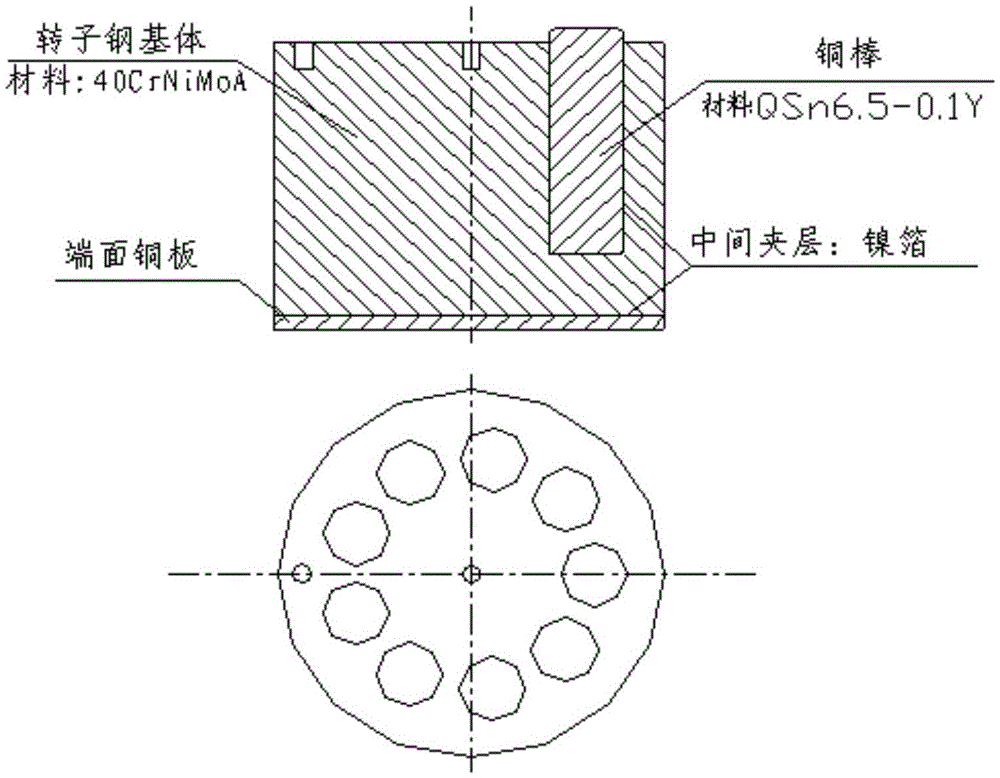

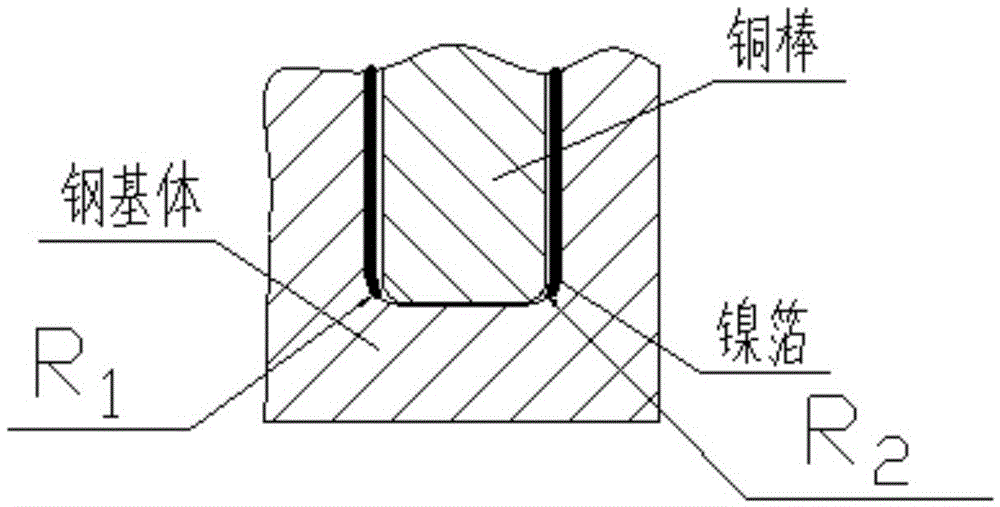

[0025] ③Nickel foil is used as the welding transition layer material, and the rotor steel matrix, copper rods and rotor end copper plates are assembled;

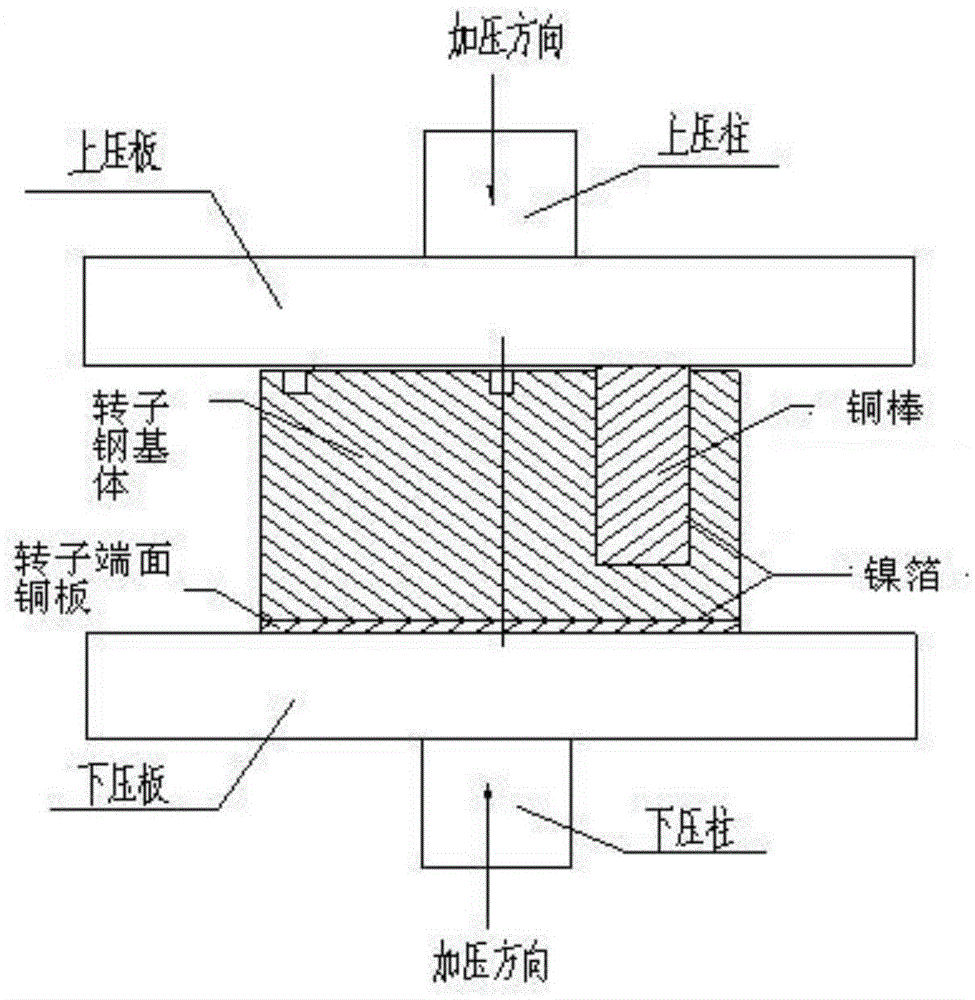

[0026] ④Put the assembled rotor welding assembly into the welding furnace by axial pressure for diffusion welding.

[0027] Preferably, the step ① is specifically: the roughness of the sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com