Novel packaging equipment and novel packaging method

A new type of packaging and equipment technology, applied in the direction of wrapping paper bending device, packaging, transportation packaging, etc., can solve the problems of fluffy, material waste, poor appearance, etc., and achieve the goal of avoiding waste, saving packaging materials, and compact and beautiful appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The following descriptions are only preferred embodiments embodying the principles of the present invention, and do not therefore limit the protection scope of the present invention.

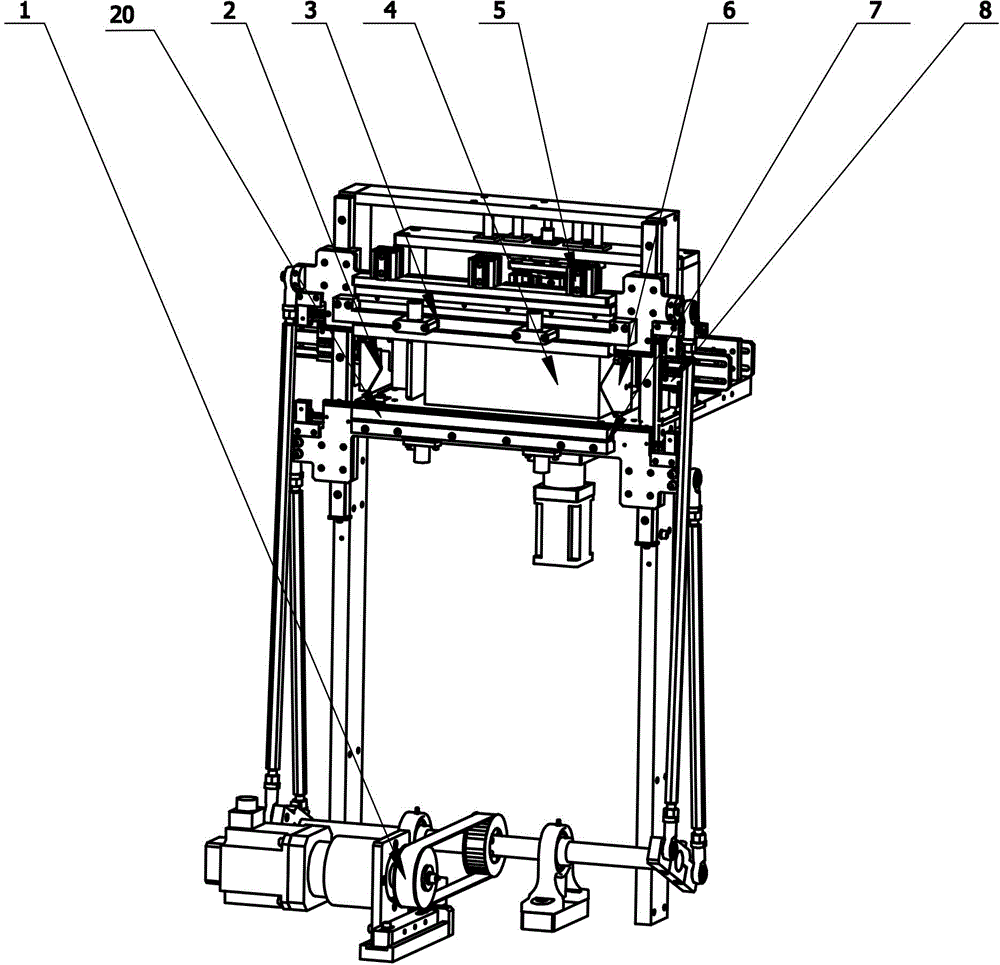

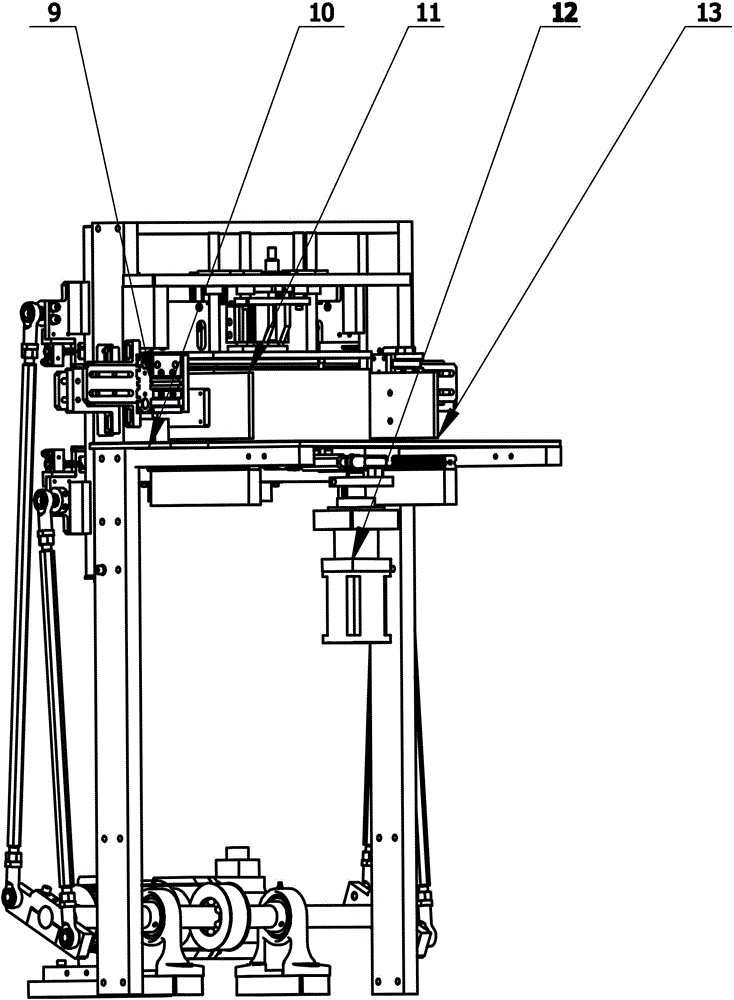

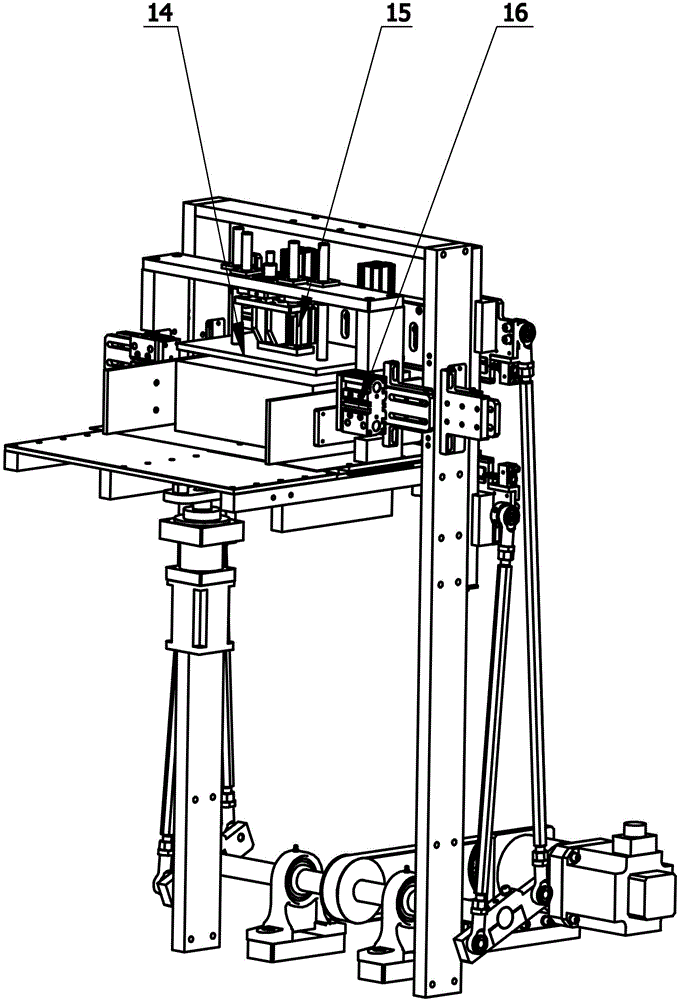

[0057] Such as Figures 1 to 4 As shown, the present invention provides a new type of packaging equipment and packaging method, using packaging materials to package the product 4, which includes an upper pressing plate 14, two side pressing plates 11, 13, two gusseted components 2, 6, a sealing component And a back cover mobile plate 10, wherein:

[0058] The upper pressing plate 14 can be driven by an upper pressing plate driving device 15 to move downwards in the vertical direction to press the packaging material on the top of the product 4;

[0059] The two side pressing plates 11, 13 are respectively arranged on both sides of the upper pressing plate 14 facing each other, and can be driven by the side pressing plate driving device 9, 16 to move relatively inward along the horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com