Installation device of prefabricated bridge deck

An installation device and prefabricated bridge technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems that the bridge deck cannot be hoisted and installed, and achieve the effects of shortening the construction period, easy control, and improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

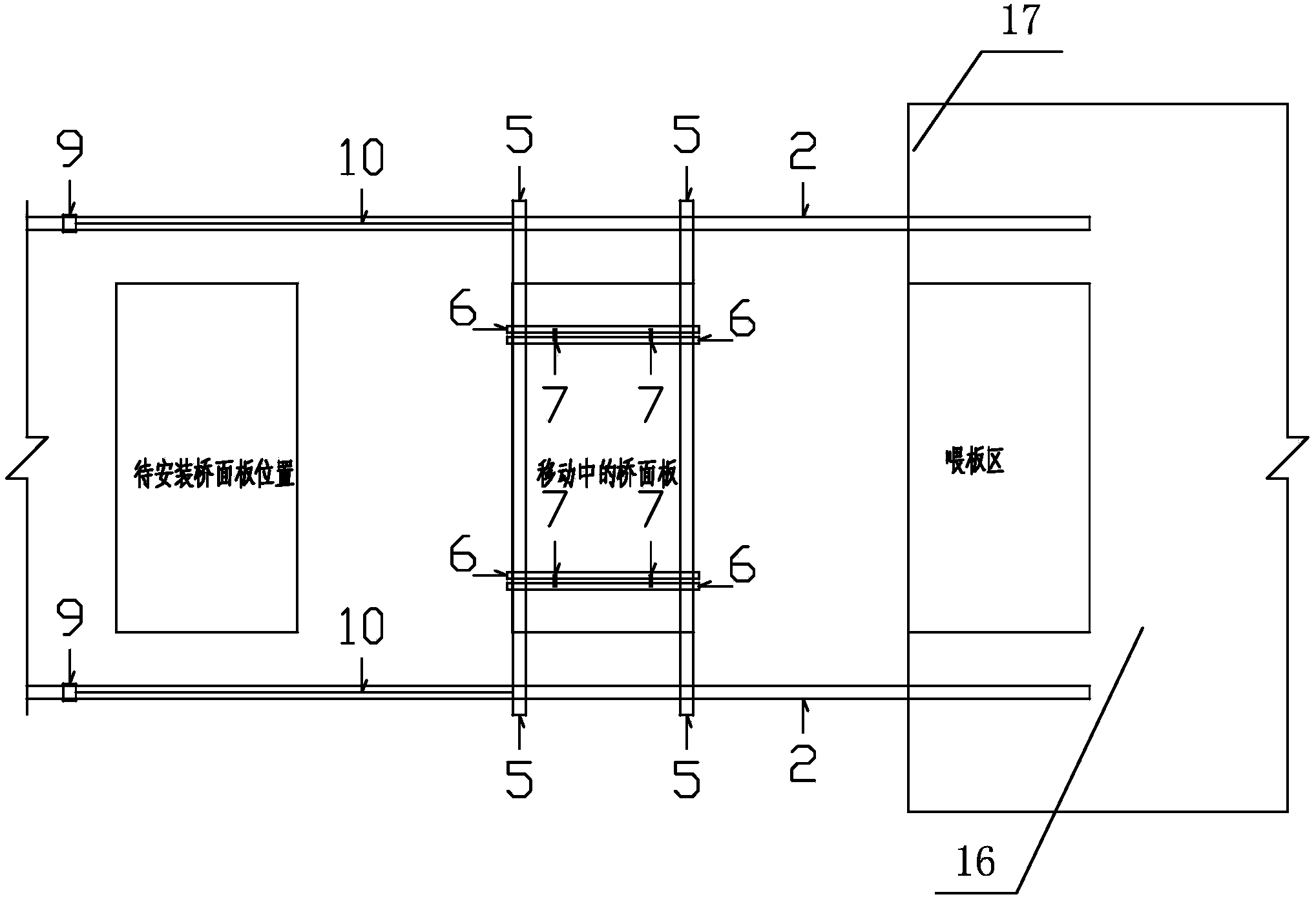

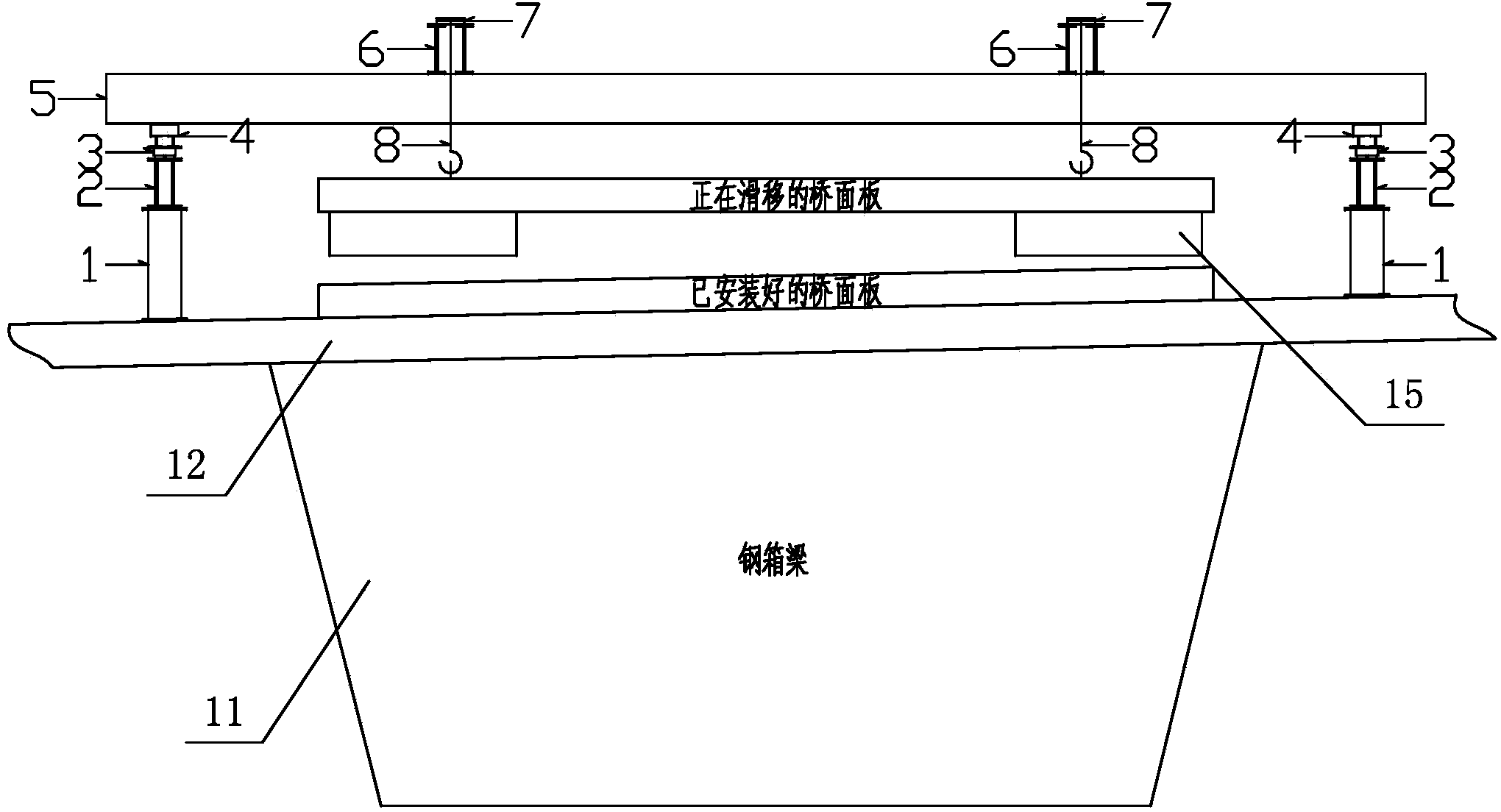

Method used

Image

Examples

Embodiment 1

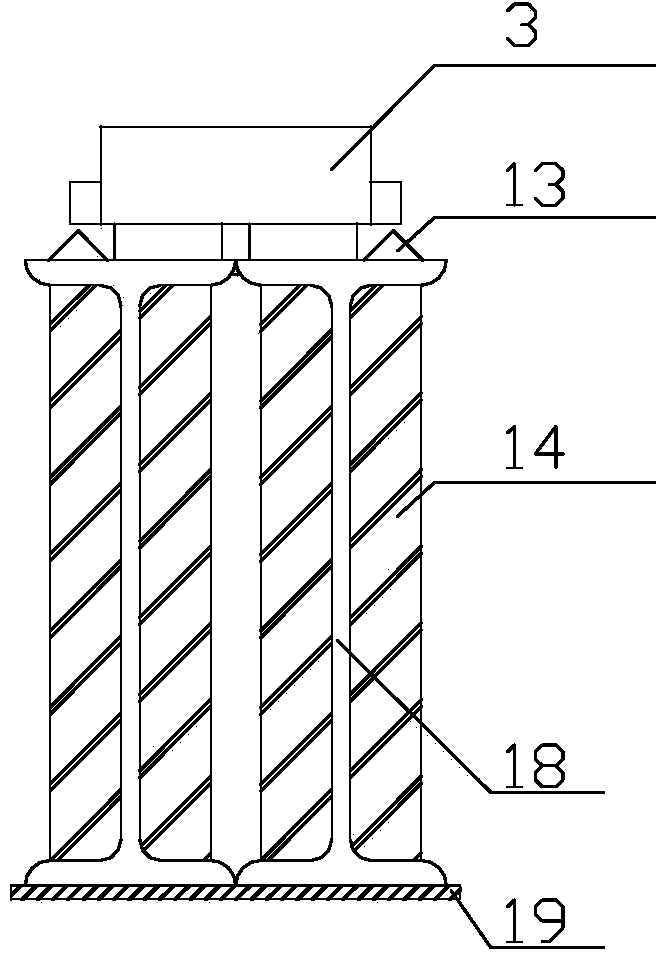

[0024] (1) Processing and installation of round steel pipe supports: The round steel pipe supports are processed by Φ299*10mm round pipes. The height can be adjusted by the longitudinal and transverse slopes to ensure that the top surface is level or not more than 1% slope. A 400*400*20mmQ235 steel plate is welded on the upper and lower ends. The round steel pipe supports are manually transported and installed, and the lower end is welded to the steel box girder overhangs, with a spacing of 4.65m. The round steel pipes can be replaced by materials such as I-beams.

[0025] (2) Longitudinal slide beam processing and installation: The longitudinal slide beam is processed by 45b I-beam, and the length of a single group is 12m. The I-beam is welded with a stiffening plate along the longitudinal spacing of 50cm. The stiffening plate is processed by Q235 steel plate with upper bottom 410mm, lower bottom 425mm, height 60mm, and thickness 10mm. After the stiffening plate is welded, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com