Friction planetary reducer

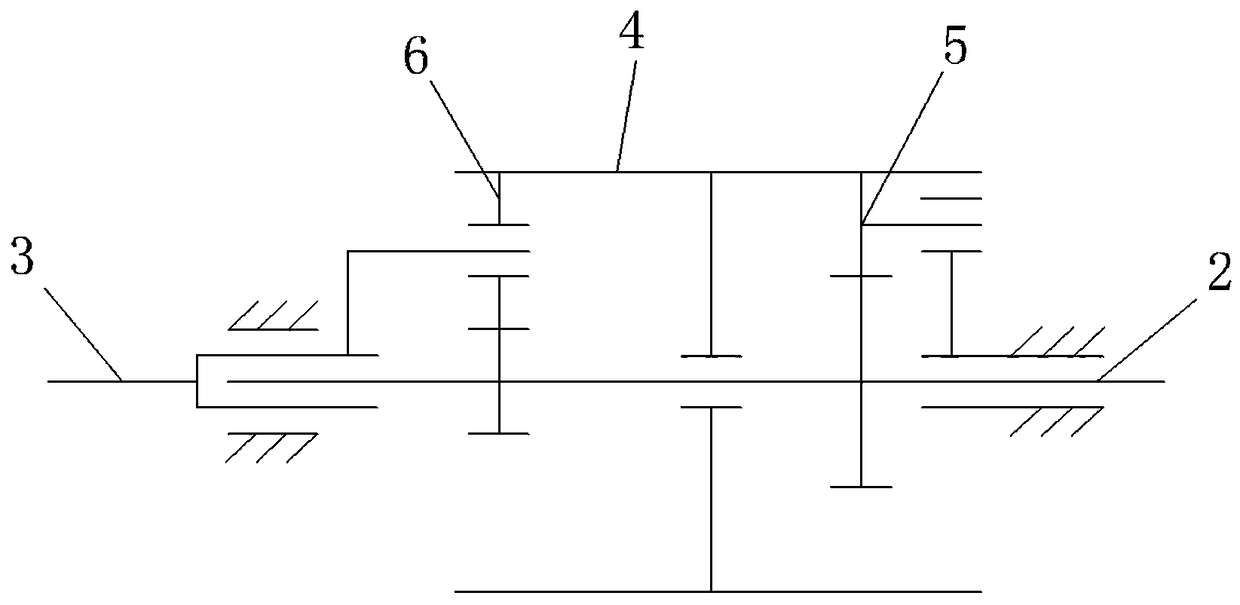

A planetary reducer, planetary technology, applied in the direction of friction transmission, transmission, belt/chain/gear, etc., can solve the problems of small transmission ratio, high production cost, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

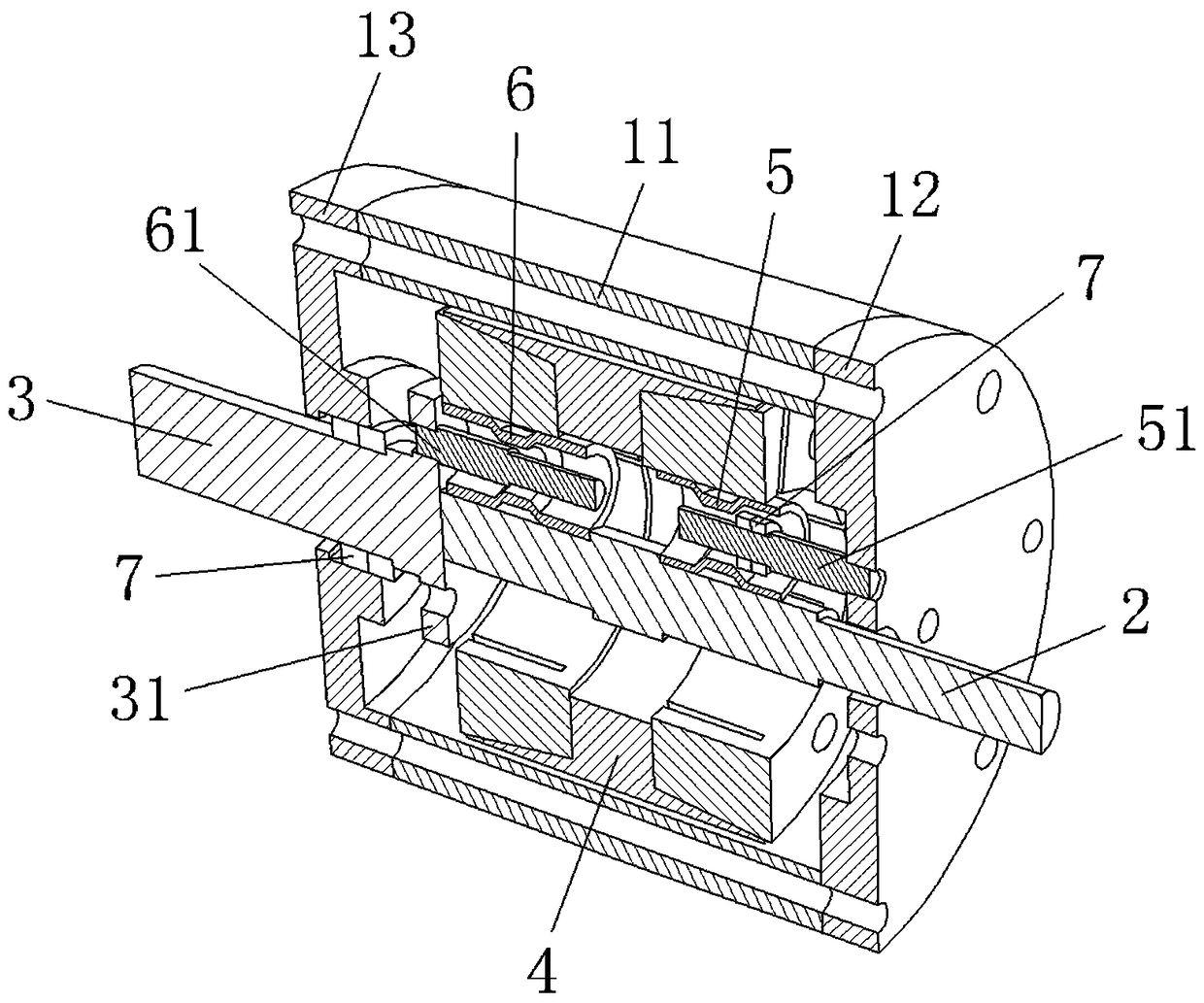

[0023] The following are specific embodiments of the utility model and in conjunction with the accompanying drawings, the technical solution of the utility model is further described, but the utility model is not limited to these embodiments.

[0024] The friction planetary reducer includes a cylindrical casing 11, an input end cover 12 and an output end cover 13 respectively arranged at both ends of the casing 11, and the shape of the casing 11 is as follows Figure 5 As shown, the housing 11 is connected together with the input end cover 12 and the output end cover 13 by bolts.

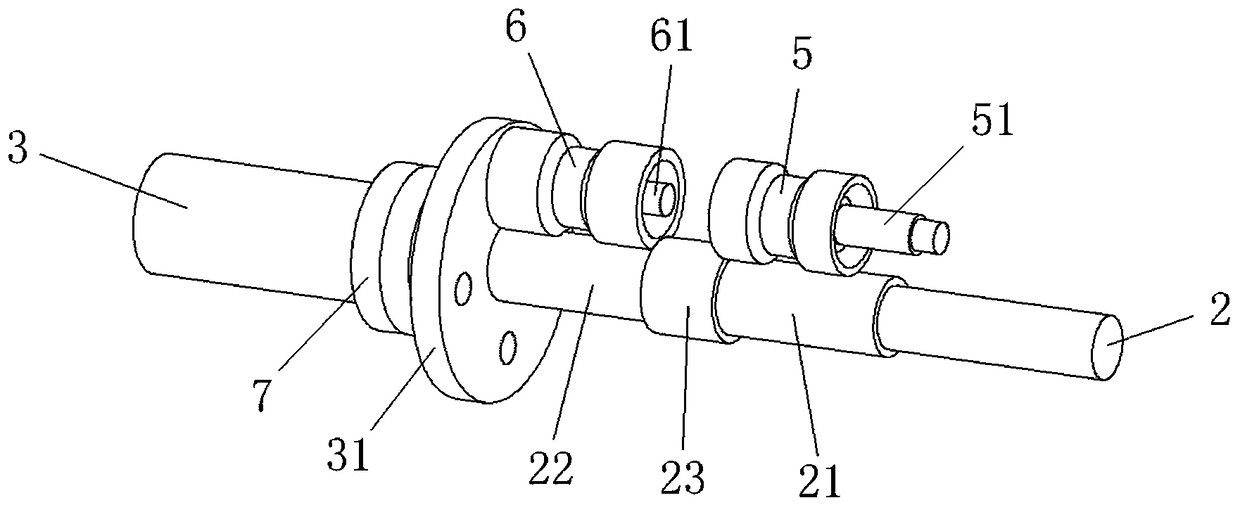

[0025] Such as figure 2 As shown, the casing 11 is pierced with an input shaft 2 and an output shaft 3 coaxially arranged with the casing 11, the input end of the input shaft 2 protrudes to the outside of the input end cover 12, and the output end of the output shaft 3 protrudes from the output The outside of the end cap 13. Specifically, such as image 3 As shown, the middle part of the input s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com