Patents

Literature

30results about How to "No transmission gap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processing equipment

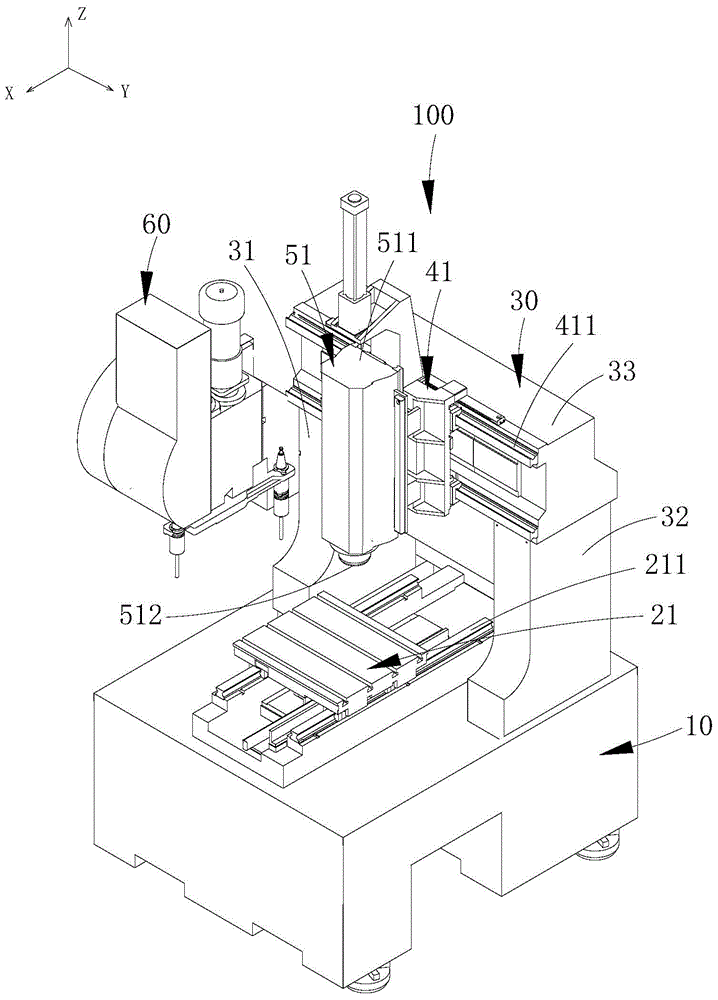

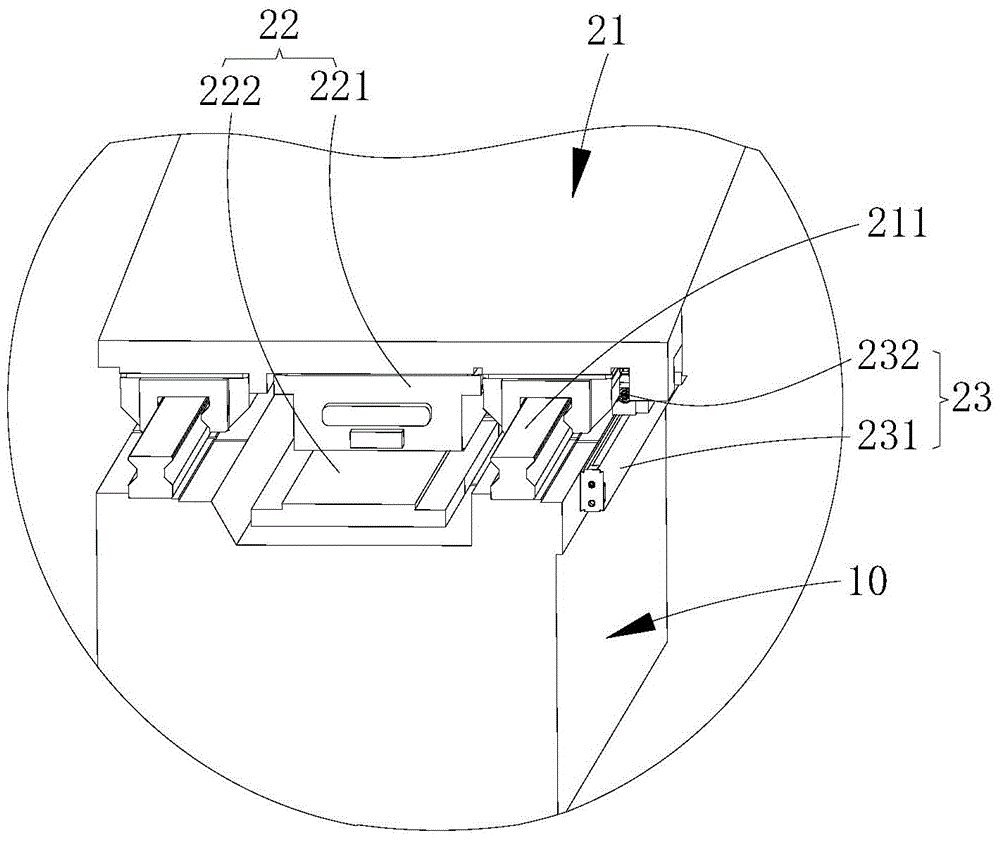

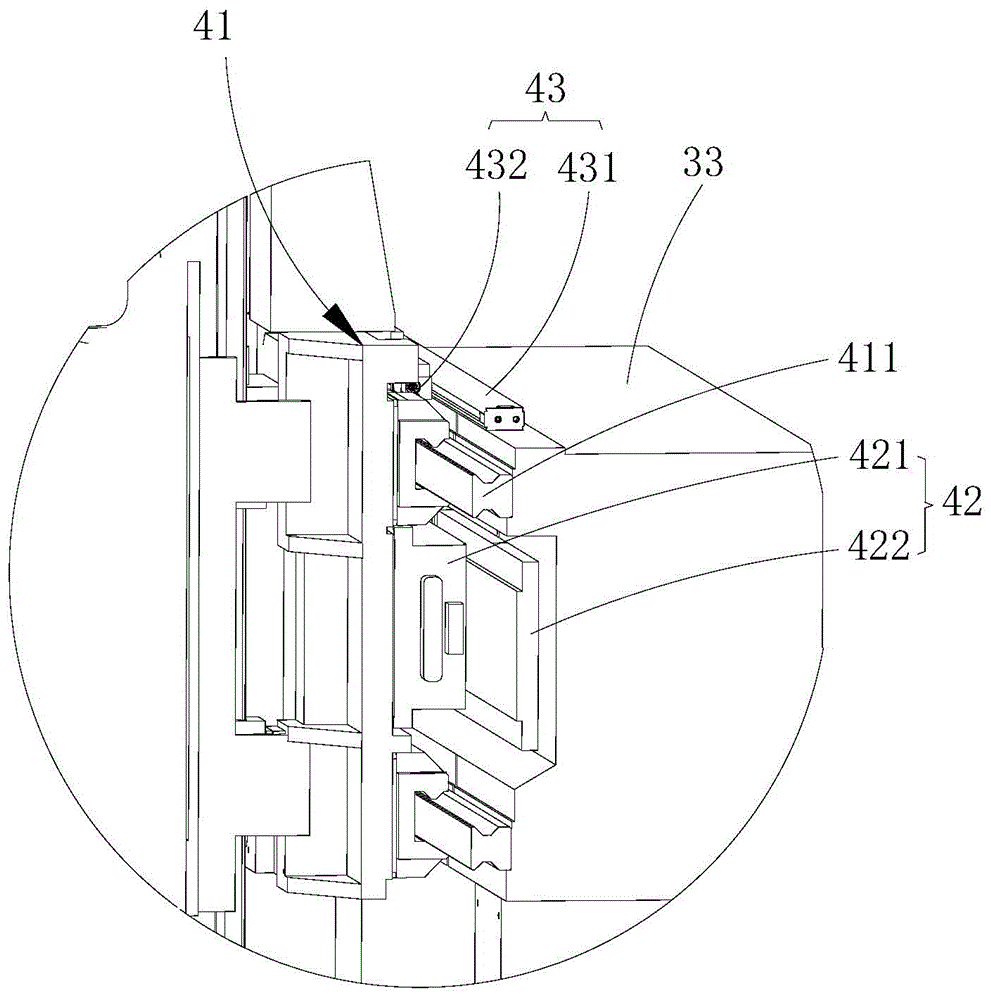

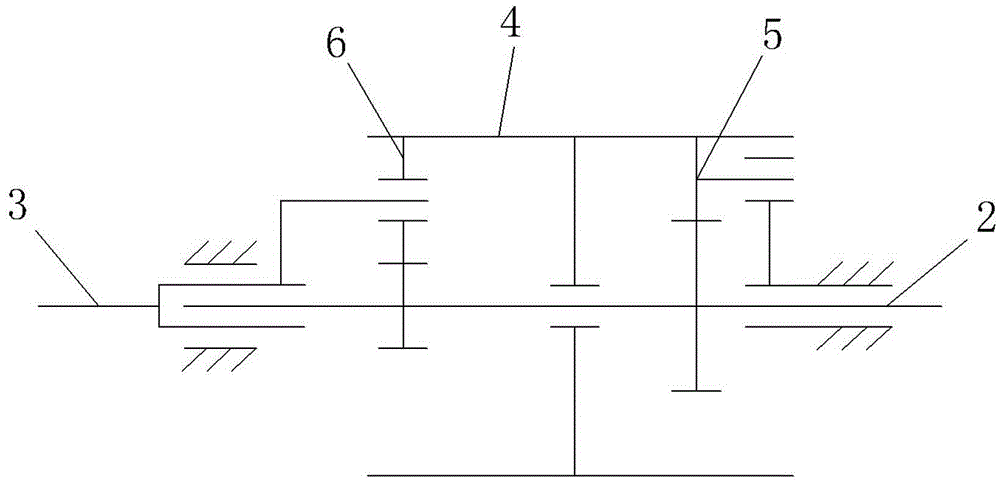

InactiveCN105619181AGuaranteed accuracyGuaranteed processing efficiencyMeasurement/indication equipmentsLarge fixed membersControl systemLinear motor

The invention discloses processing equipment. The processing equipment comprises a base, an X axis work platform, a first linear motor, a first metering device, a bracket, a Y axis sliding carriage, a second linear motor, a second metering device, a Z axis spindle box, a third linear motor, a third metering device, a tool changer and a control system, wherein through the arrangement of the first linear motor and the first metering device, the sliding precision of the X axis work platform is effectively ensured; through the arrangement of the second linear motor and the second metering device, the sliding precision of the Y axis sliding carriage is effectively ensured; through the arrangement of the third linear motor and the third metering device, the sliding precision of the Z axis spindle box is effectively ensured; and in this way, when a spindle of the Z axis spindle box processes a workpiece, higher workpiece processing precision can be obtained, and at the same time, the processing efficiency of the whole machine is ensured. Due to the adoption of linear motor driving, the processing equipment adopting the transmission mode is high in acceleration speed, compact in structure, free of transmission clearance and free of wear, and the reliability improvement of the whole machine is facilitated.

Owner:深圳市万嘉科技有限公司 +1

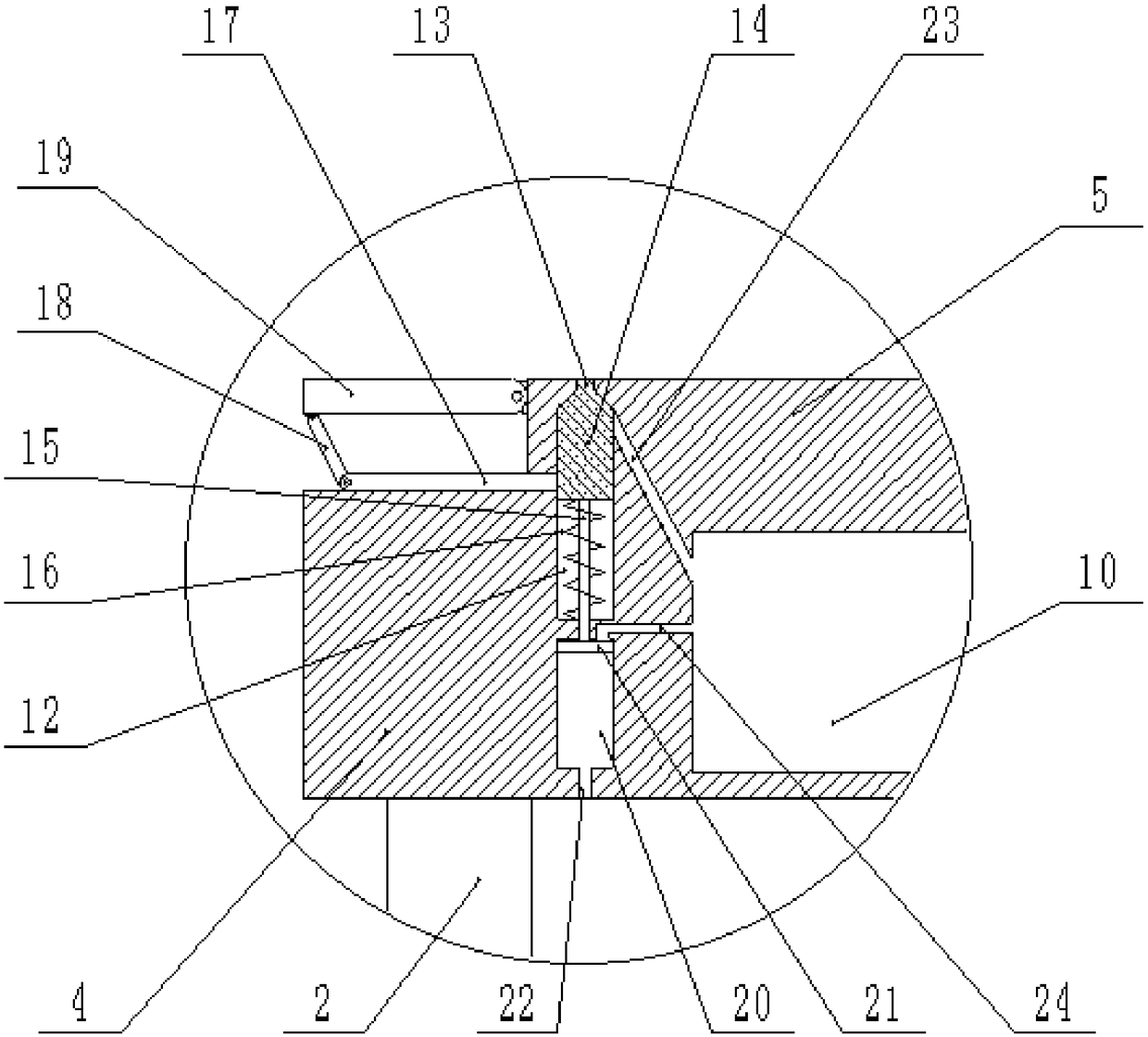

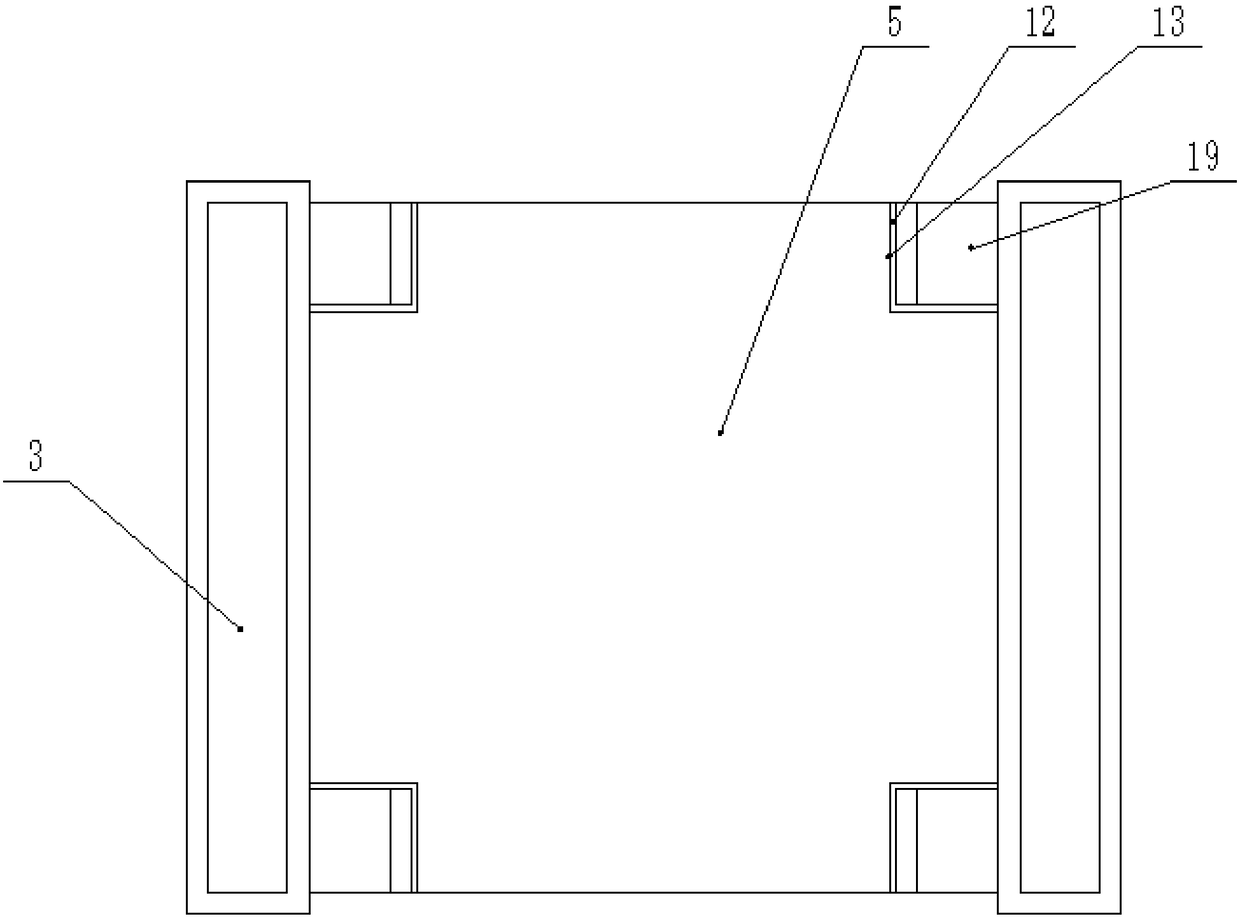

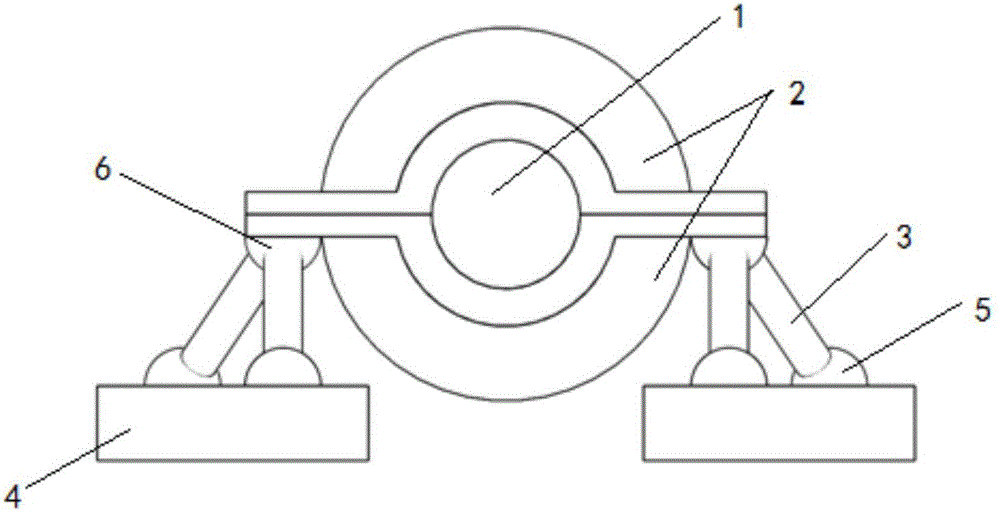

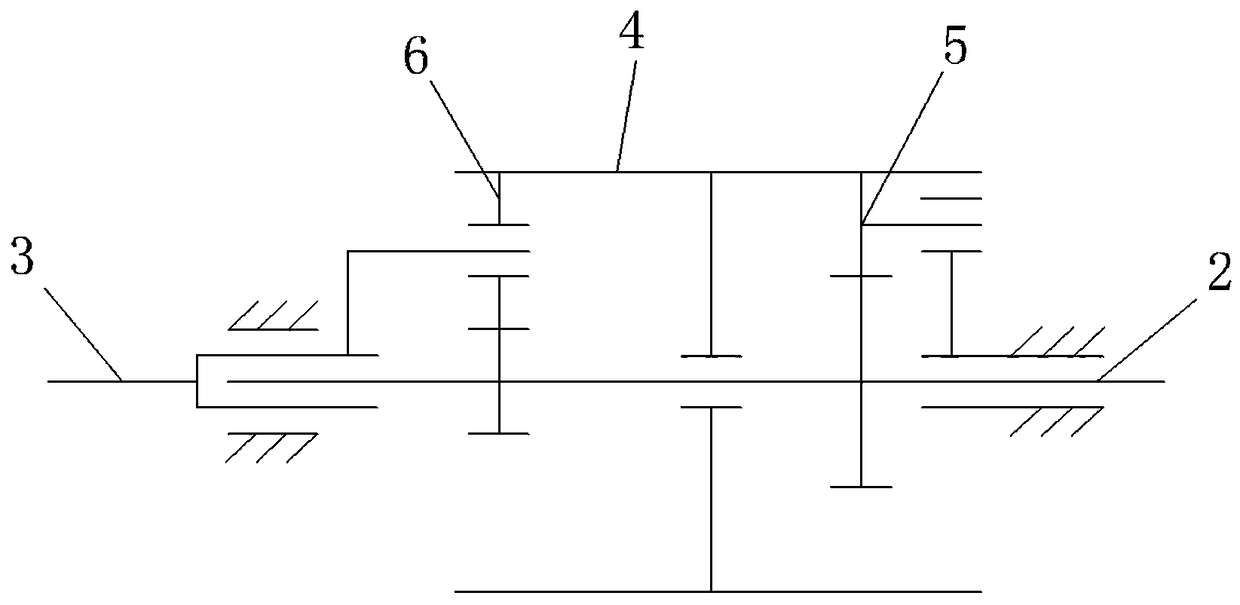

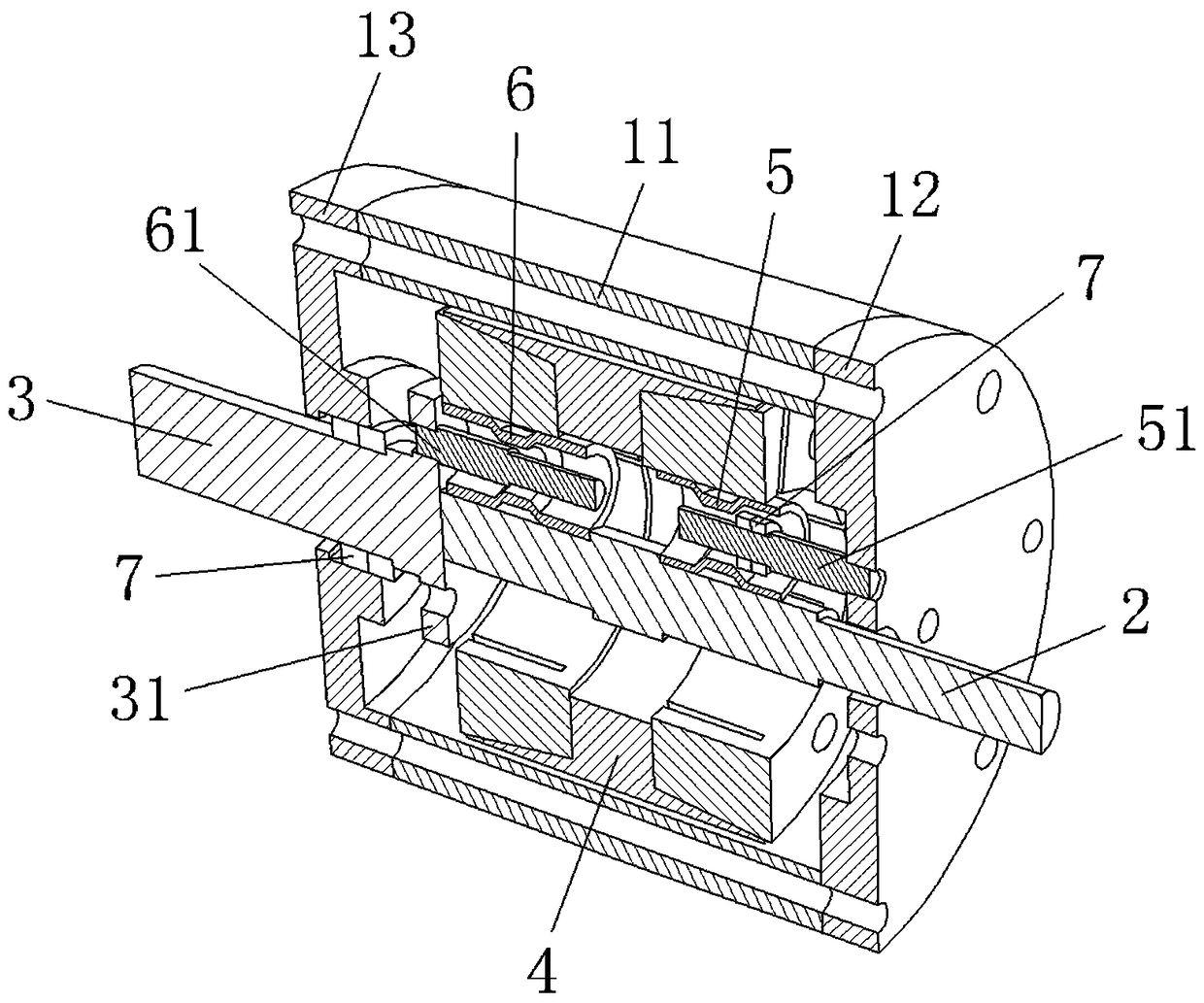

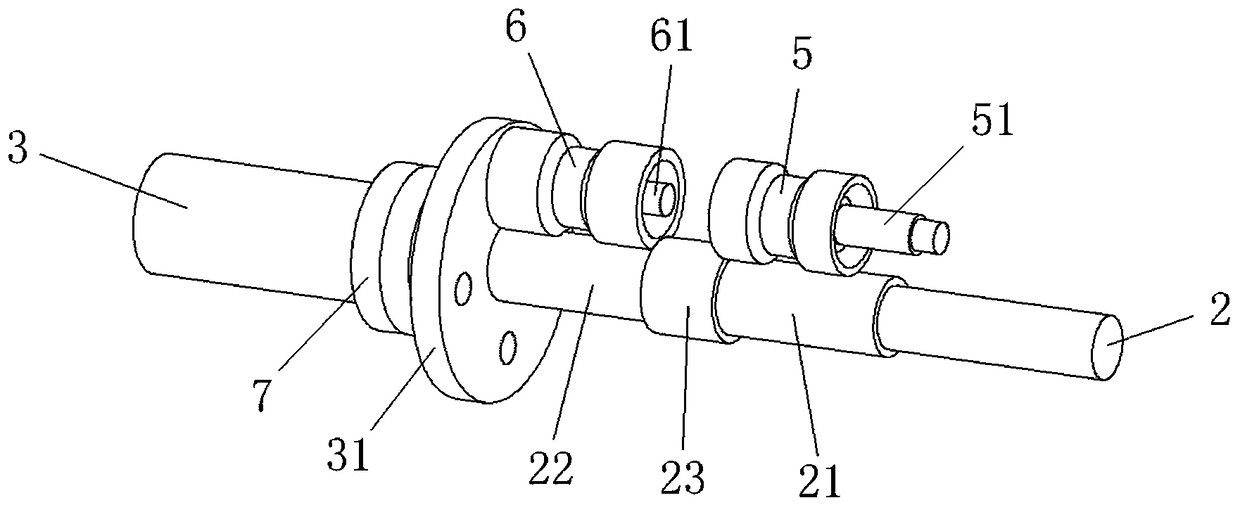

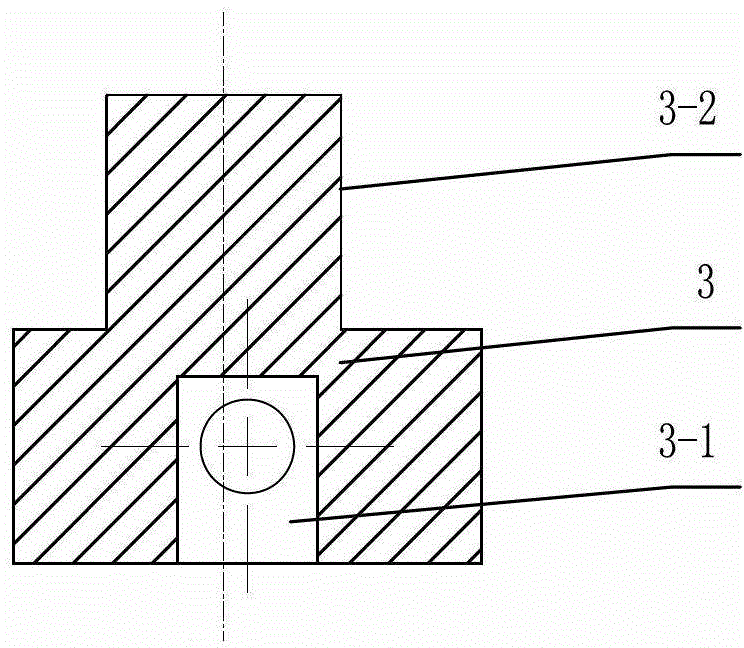

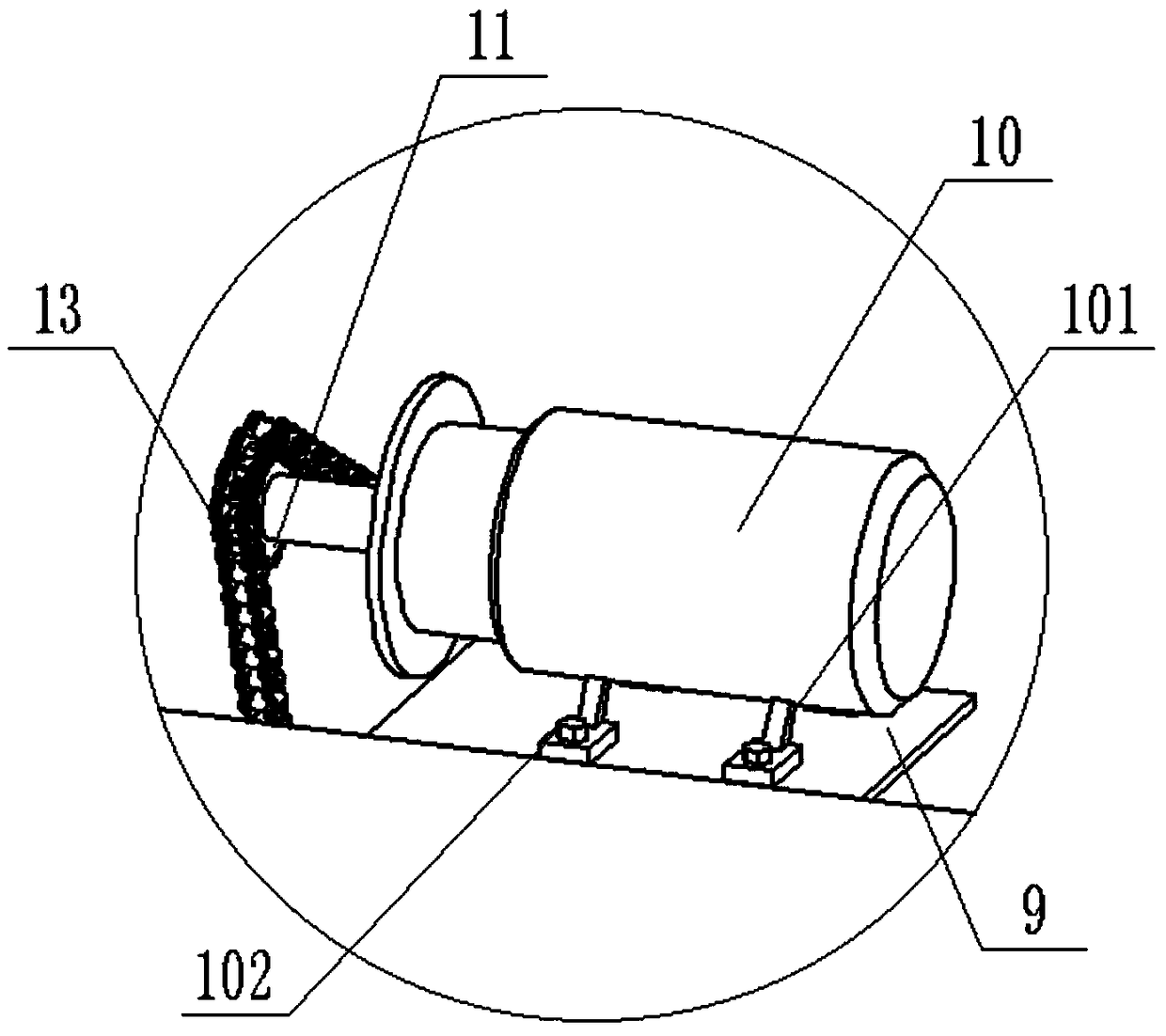

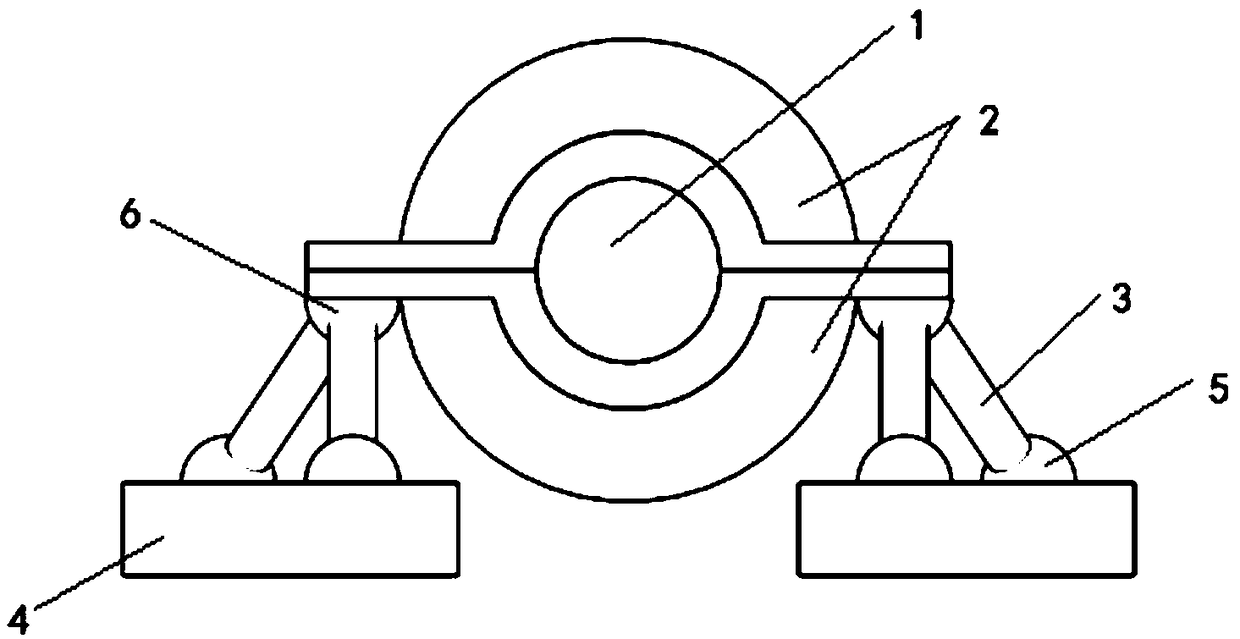

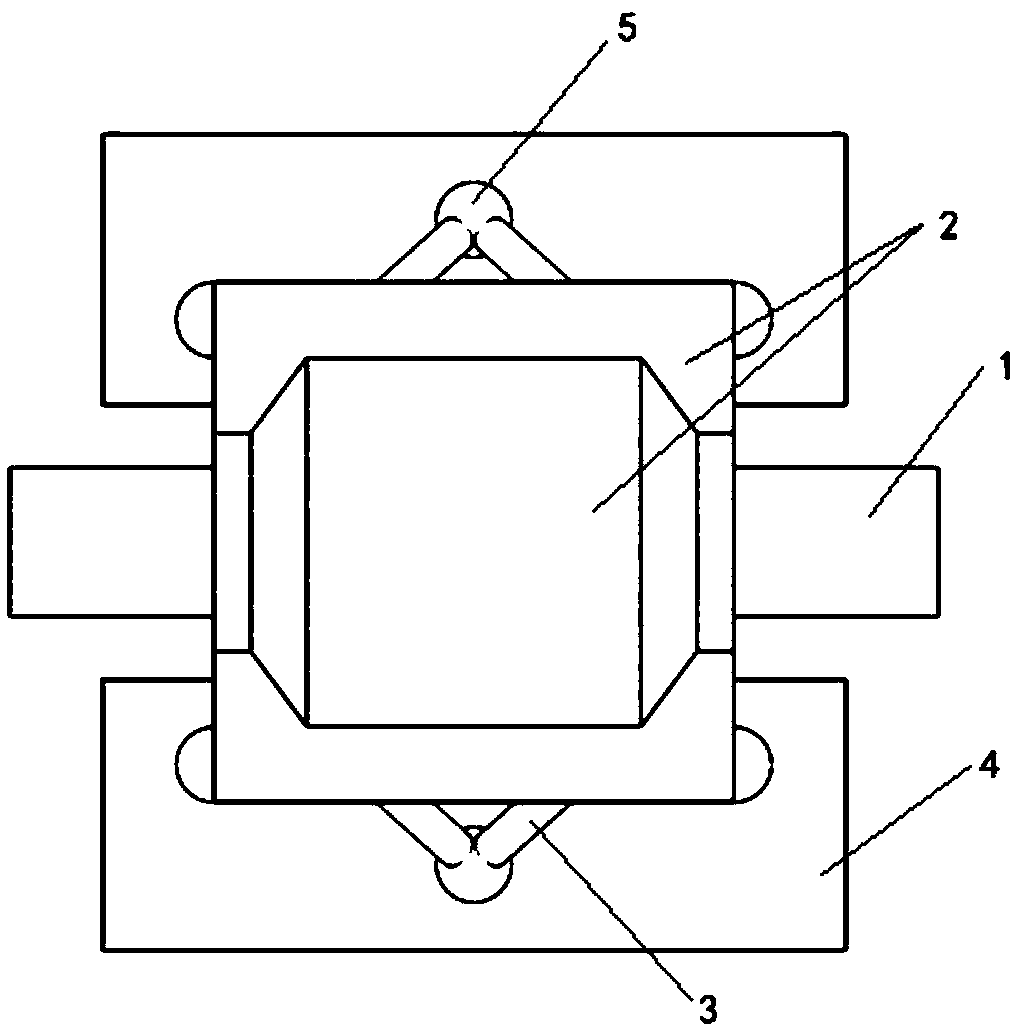

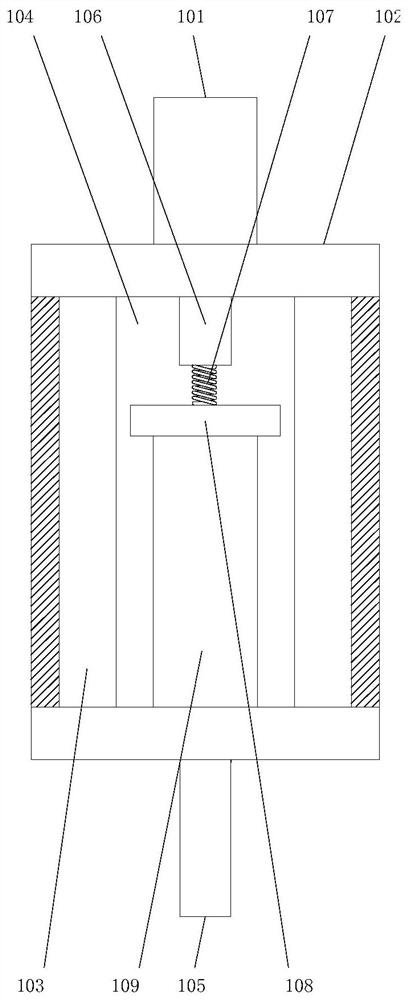

Friction planetary reducer

InactiveCN104061295ALarge transmission ratioNo transmission gapGearing detailsFriction gearingsReduction driveReducer

The invention provides a friction planetary reducer, belongs to the technical field of machineries, and solves the problem that the conventional gear planetary reducer is small in transmission ratio. The friction planetary reducer comprises a cylindrical shell, an input end cover and an output end cover, wherein the input end cover and the output end cover are arranged at two ends of the shell respectively; an input shaft and an output shaft are arranged in the shell; the middle of the input shaft is provided with an annular step A positioned in the shell; the output end of the input shaft is provided with an annular step B positioned in the shell; a flexible cylinder, with which the input shaft is sleeved, is arranged in the shell; a plurality of fixed flexible gears coaxial with the input shaft are arranged between the flexible cylinder and the annular step A; a rotating shaft A, one end of which is fixed on the input end cover, is arranged in each fixed flexible gear; a plurality of planetary flexible gears coaxial with the input shaft are arranged between the flexible cylinder and the annular step B; a rotating shaft B, one end of which is fixed on the output shaft, is arranged in each planetary flexible gear. The friction planetary reducer has the advantages of being large in transmission ratio, simple in structure, and the like.

Owner:温岭市天工工量刃具科技服务中心有限公司

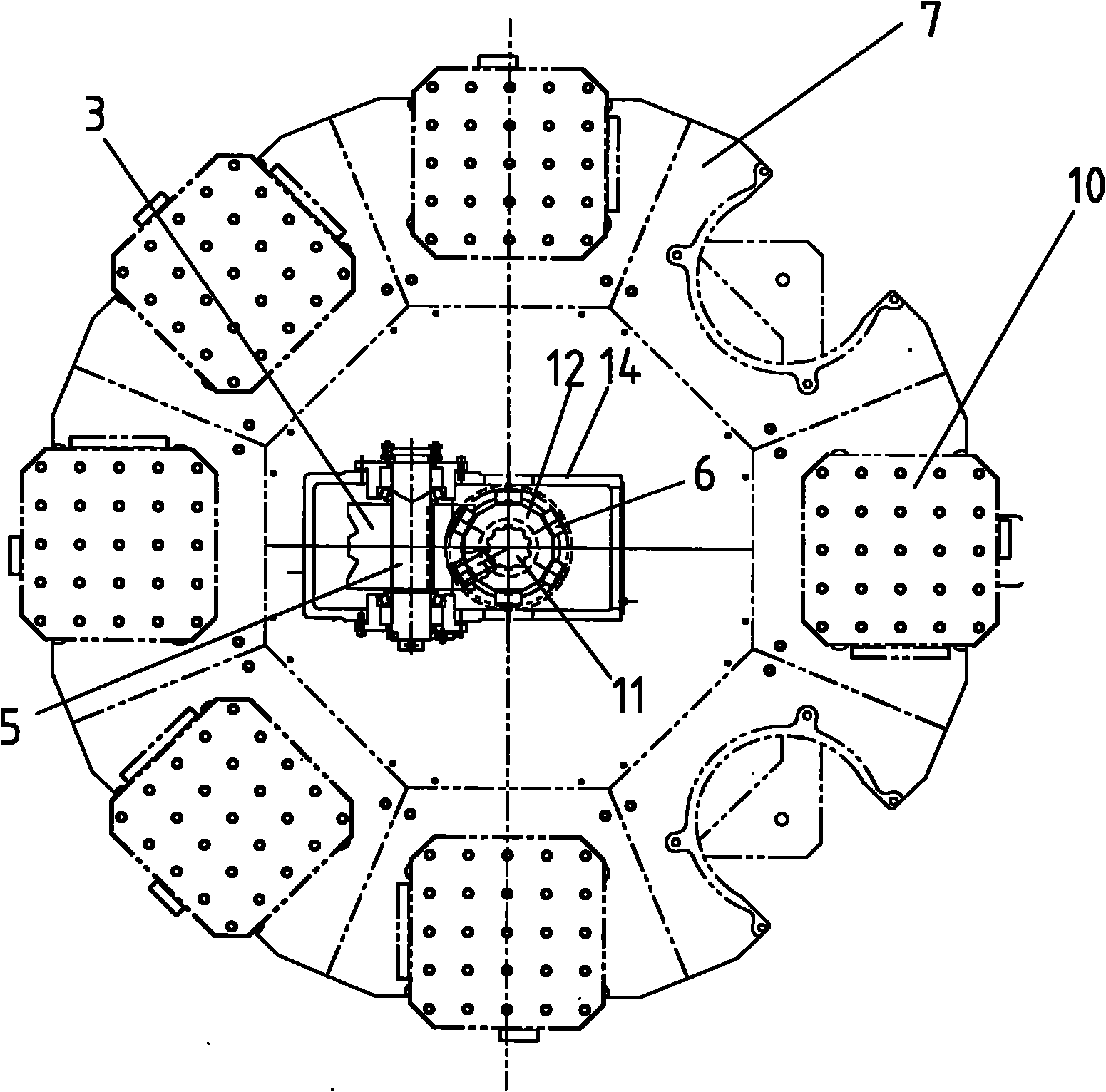

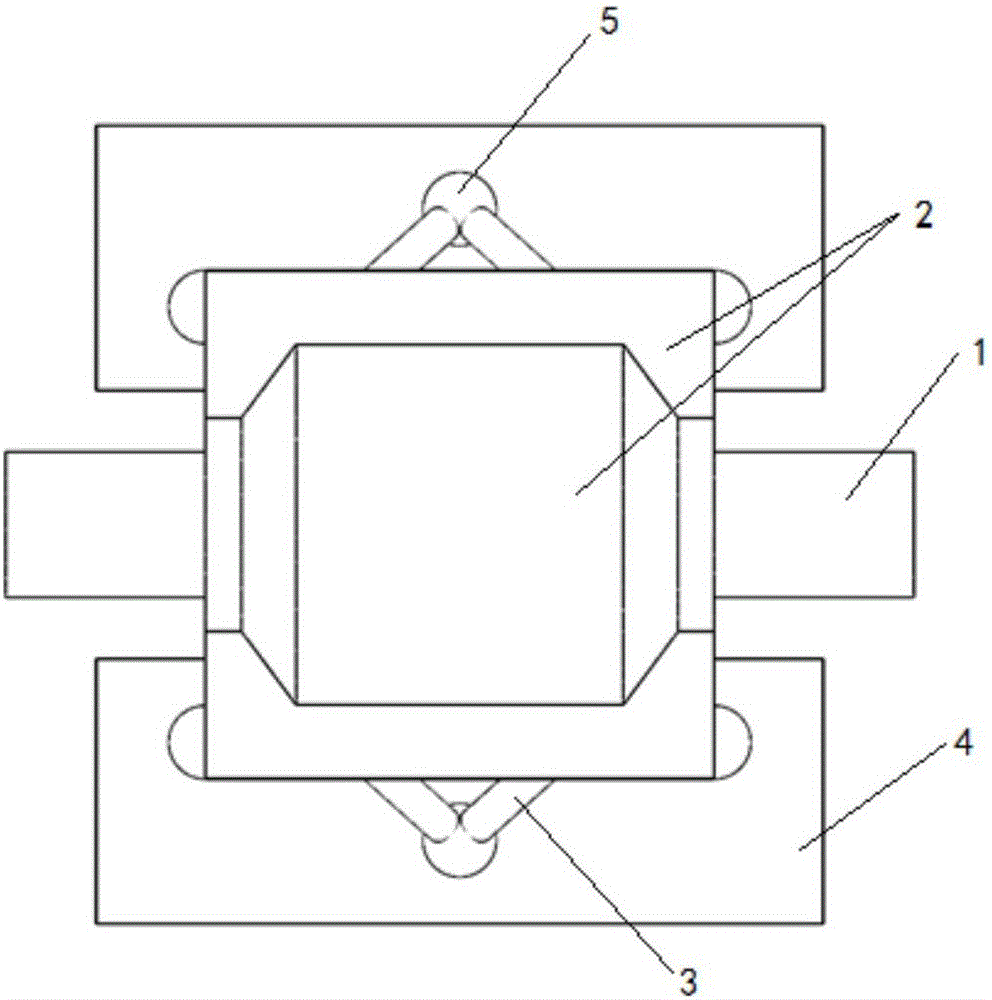

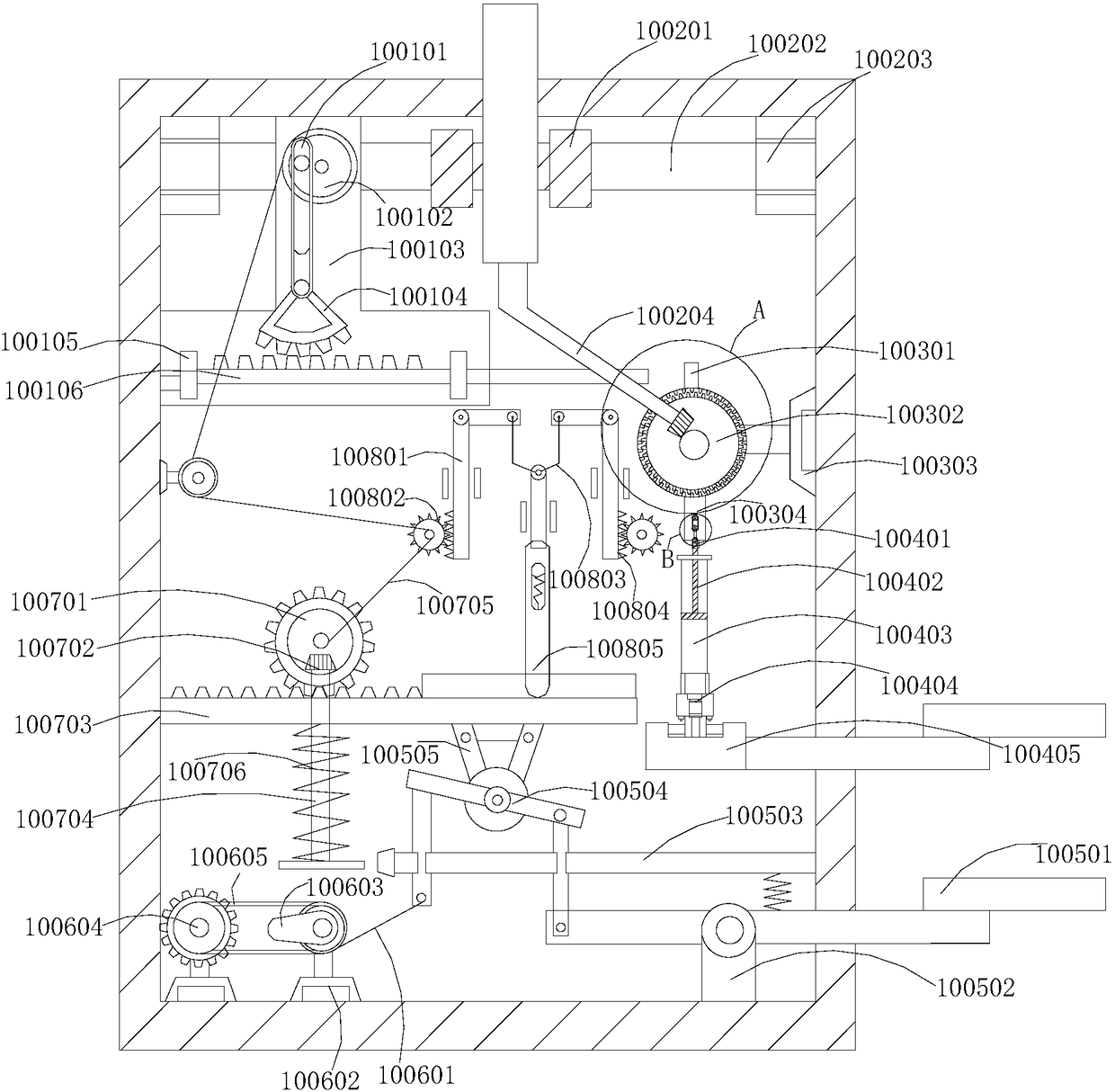

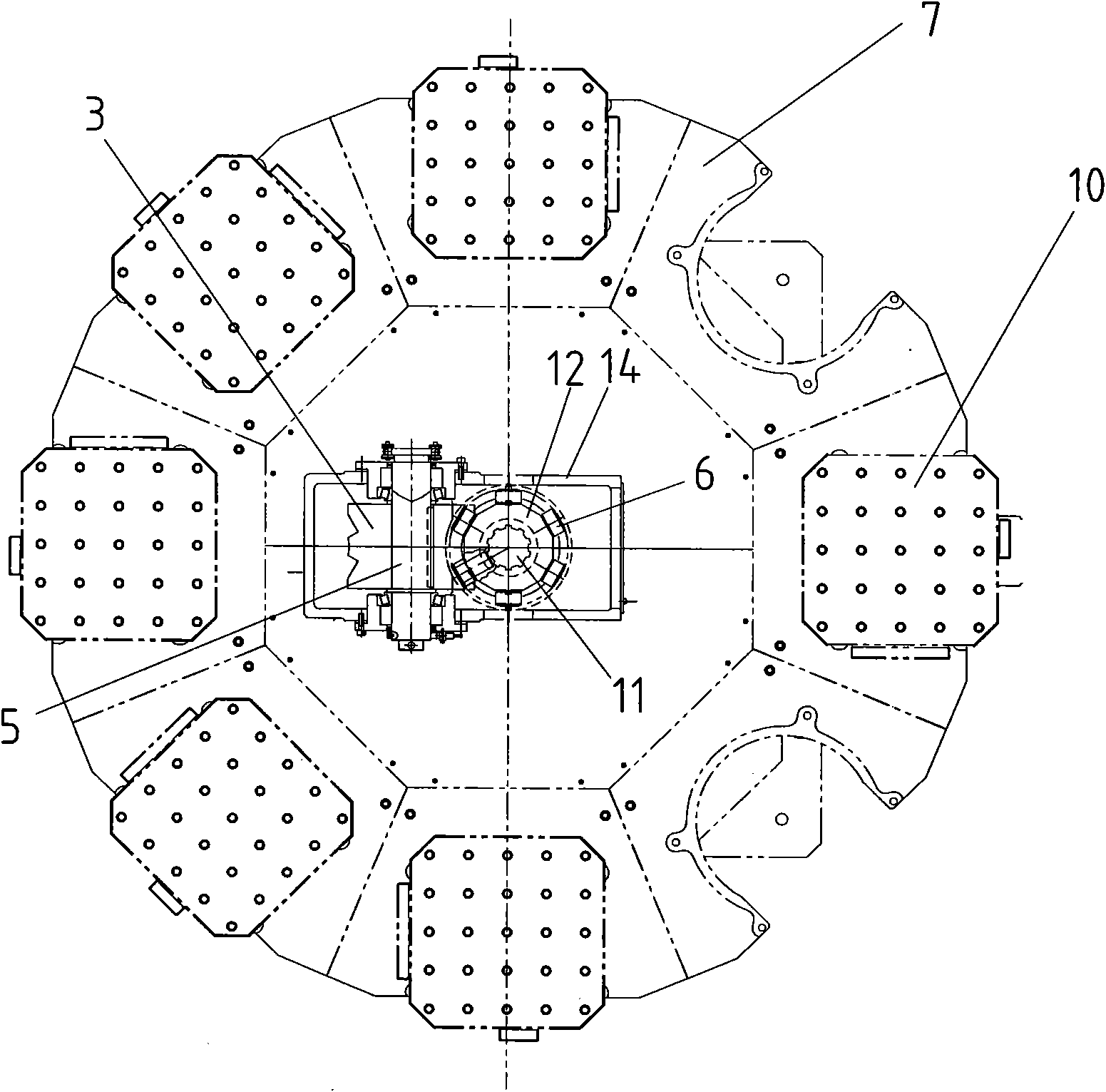

Eight-station sorting mechanism indexed by cambered surface cam

InactiveCN101982294ASimple structureSmall footprintPrecision positioning equipmentMetal working apparatusEngineeringCam

The invention discloses an eight-station sorting mechanism indexed by a cambered surface cam, comprising a rack and a motor installed on the rack, wherein an eight-station index plate is arranged above the rack, the center below the eight-station index plate is fixedly connected with a vertical shaft, the vertical shaft is installed on an installation rack fixedly connected with the rack, a supporting wheel is arranged above the rack to support the eight-station index plate, and a link transmission mechanism and a cambered surface cam transmission mechanism are arranged between the vertical shaft and the motor. The mechanism has simple integral structure, few workpieces and small land occupation, does not generate a driving gap during the conversion of positive rotation and reverse rotation, and has accurate indexing and high processing precision of workpieces.

Owner:DALIAN HUAGEN MACHINERY

Packaging box production equipment

The invention belongs to machines for manufacturing paper boxes, cartons, envelopes or paper bags, and particularly discloses packaging box production equipment which comprises a machine frame. A diecutting rule, a driving mechanism used for driving the die cutting rule and a placing table for placing materials are arranged on the machine frame, the die cutting rule is located above the placing table, the upper end face of the placing table is provided with a groove matched with the die cutting rule in shape, a filling portion is connected to the interior of the groove in a sliding mode, theshape and size of the filling portion are the same as those of the die cutting rule, a pressing spring is arranged between the filling portion and the bottom face of the groove, an a paper scrap collection mechanism is arranged in the placing table and driven by the filling portion. The problem that when paper boards are subjected die cutting in the prior art, the paper boards cannot be completelycut off is solved.

Owner:重庆漱心斋文化产业发展有限公司

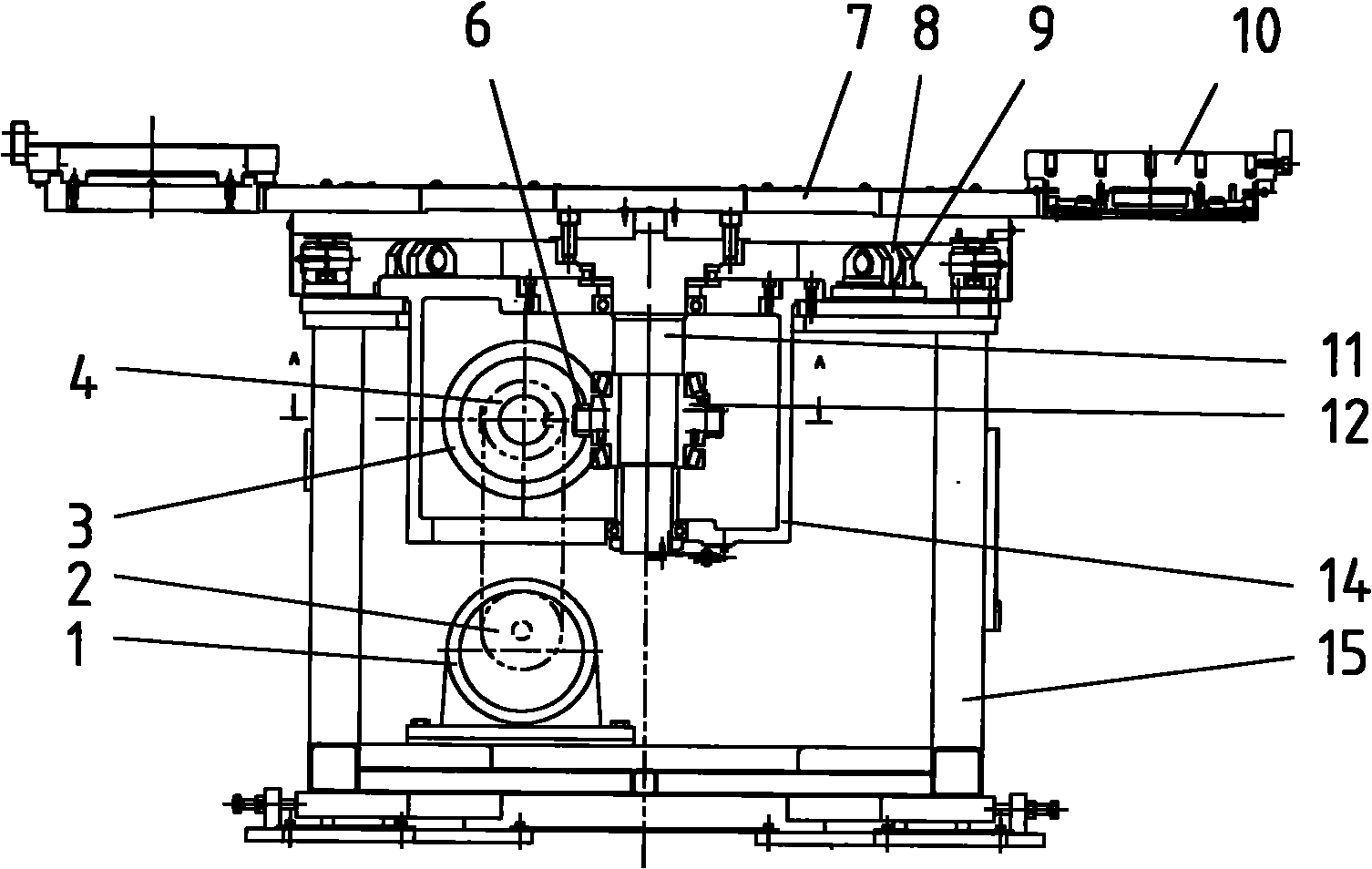

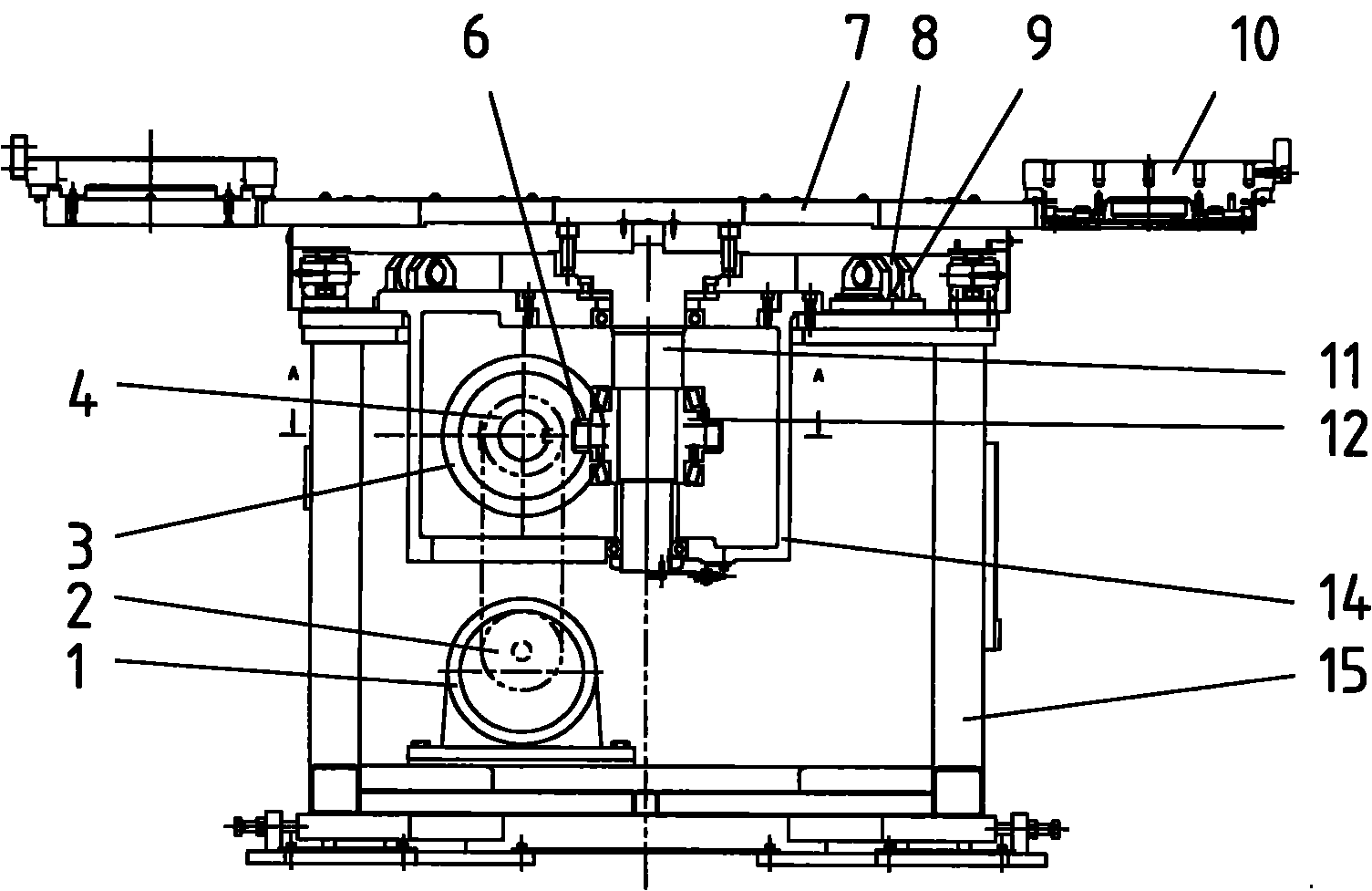

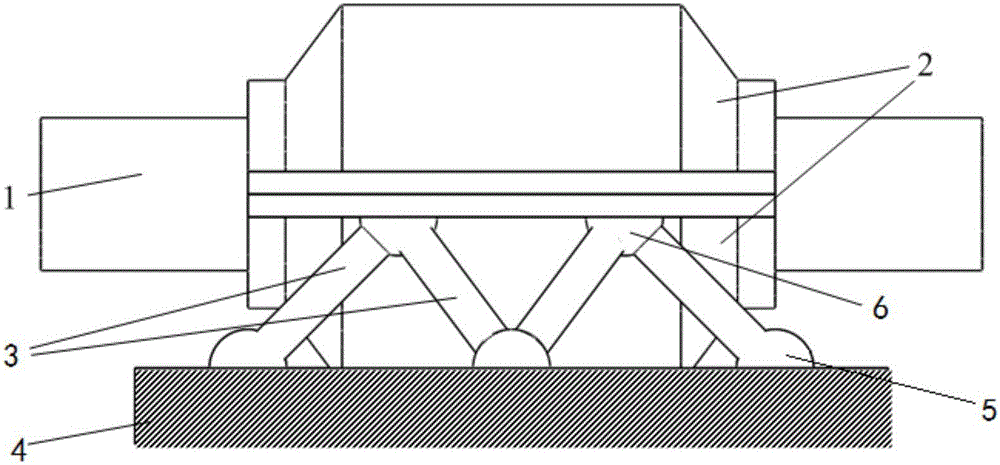

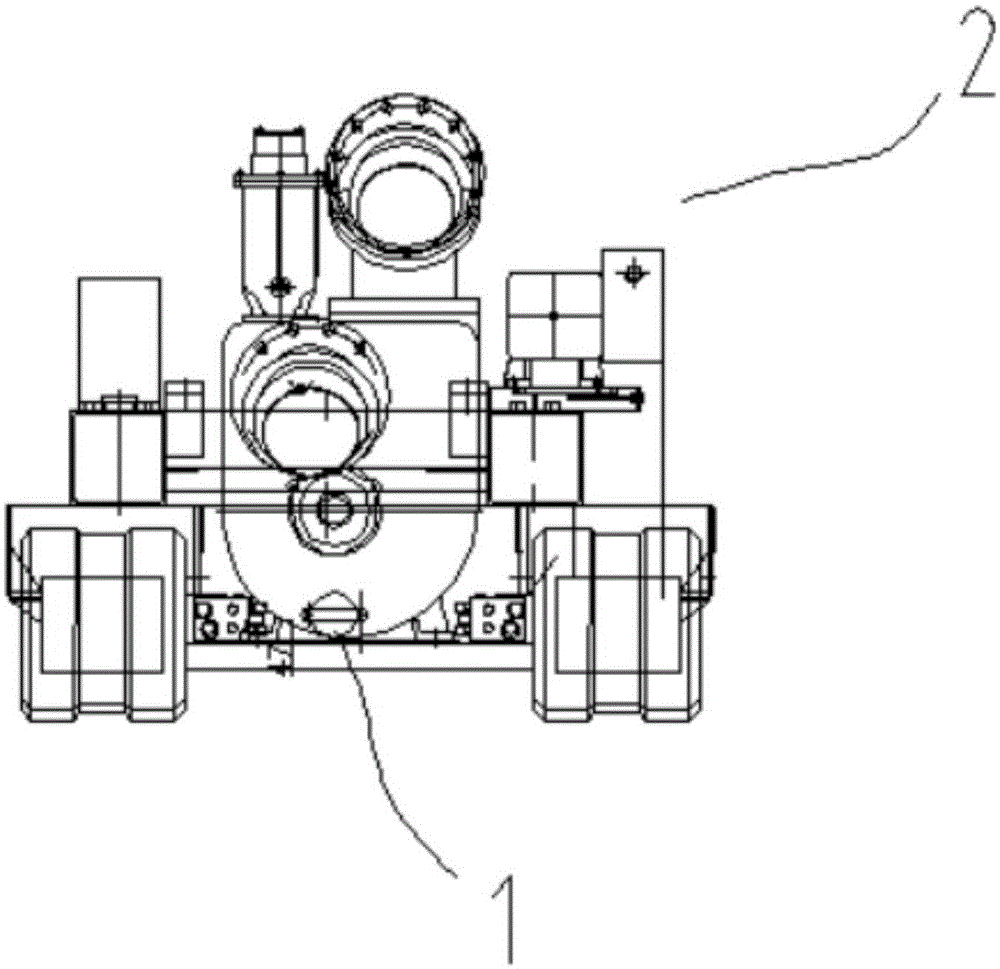

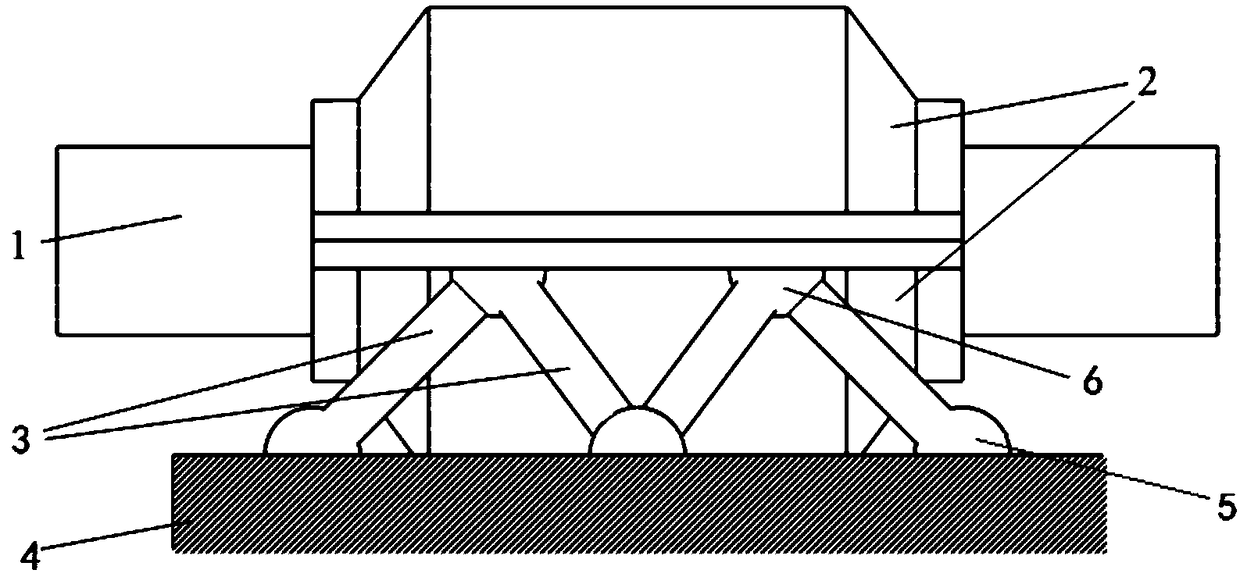

Hydraulic-driven eight-foot thrust bearing base

ActiveCN106640985AUniform load distributionReduce vibration and noisePropulsive elementsPropulsive transmissionWork performanceThrust bearing

The invention discloses a hydraulic-driven eight-foot thrust bearing base, comprising a shaft, a thrust bearing, a support assembly and a base, wherein the shaft passes through the thrust bearing; the support assembly comprises two actuator groups which are respectively and symmetrically distributed at two sides of the thrust bearing; each actuator group comprises four actuators, two upper part connecting blocks positioned at one side of the thrust bearing, and three lower part connecting blocks arranged on the base; an 'M'-shaped structure is formed by the actuators, the upper part connecting blocks and the lower part connecting blocks of each actuator group; the upper part connecting blocks, the lower part connecting blocks and the actuators are connected in a way of spherical hinge connection. The thrust bearing base provided by the invention is simple, efficient and flexible; after the design is adopted, the bearing load can be evenly distributed, the working performance of a shaft system is improved, the normal operation of the shaft system is guaranteed, and active and passive control can be also effectively carried out on the vibration of the shaft system.

Owner:SHANGHAI JIAO TONG UNIV

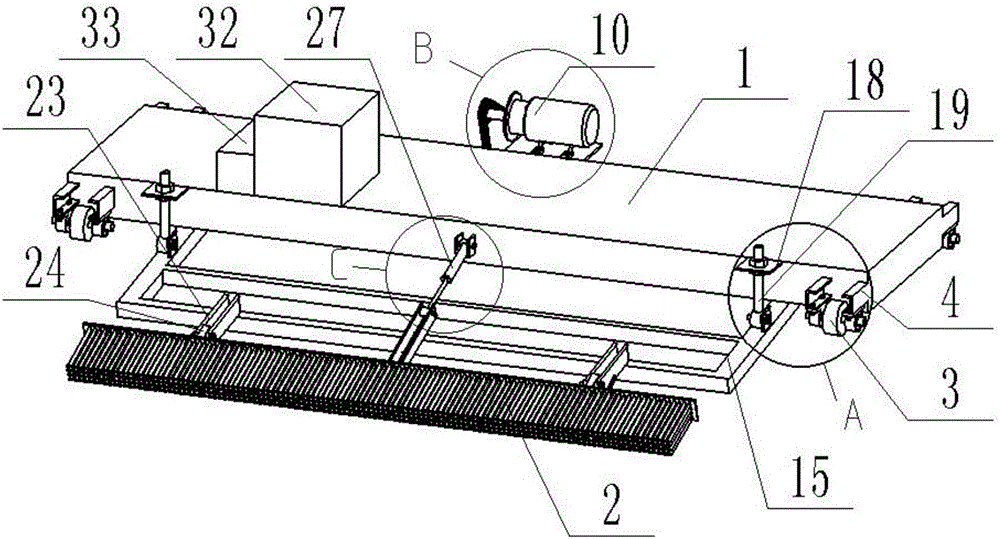

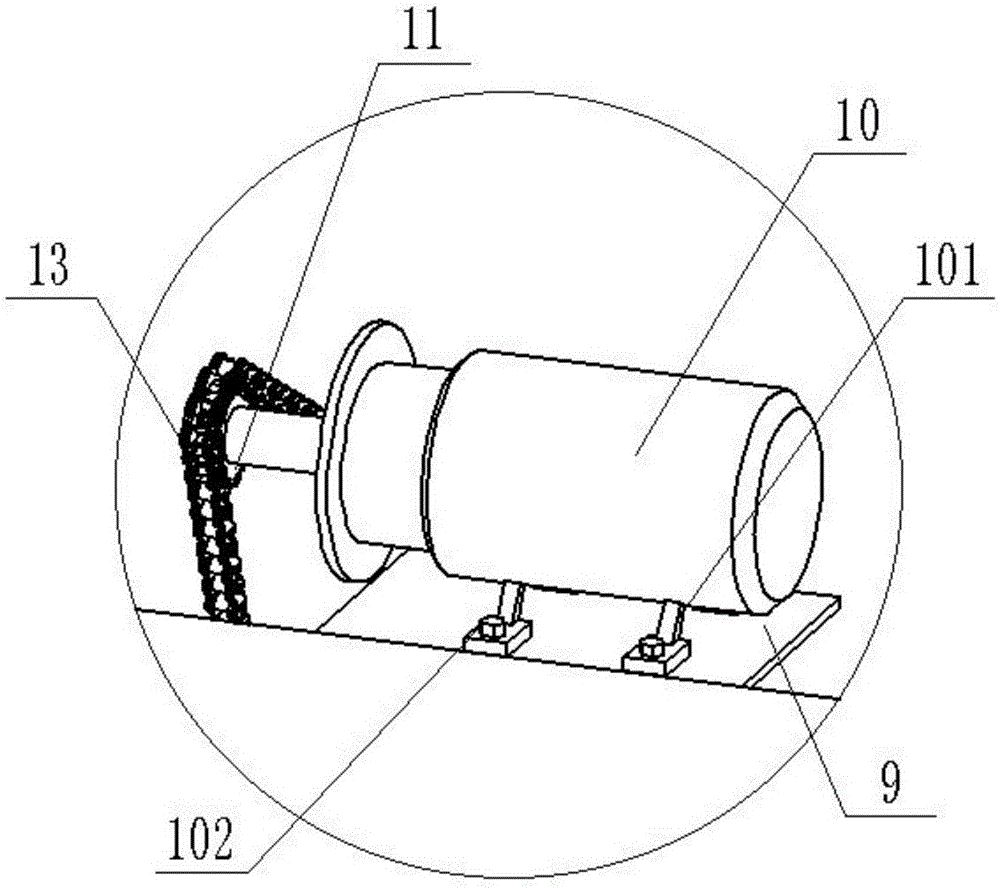

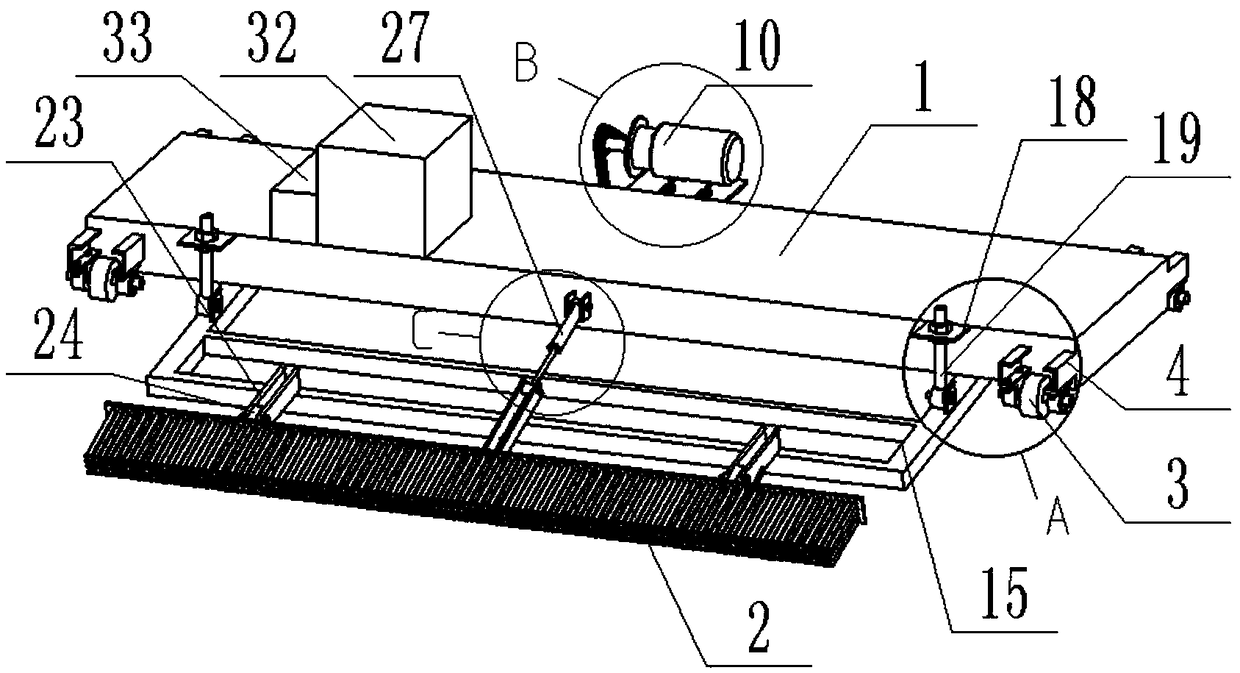

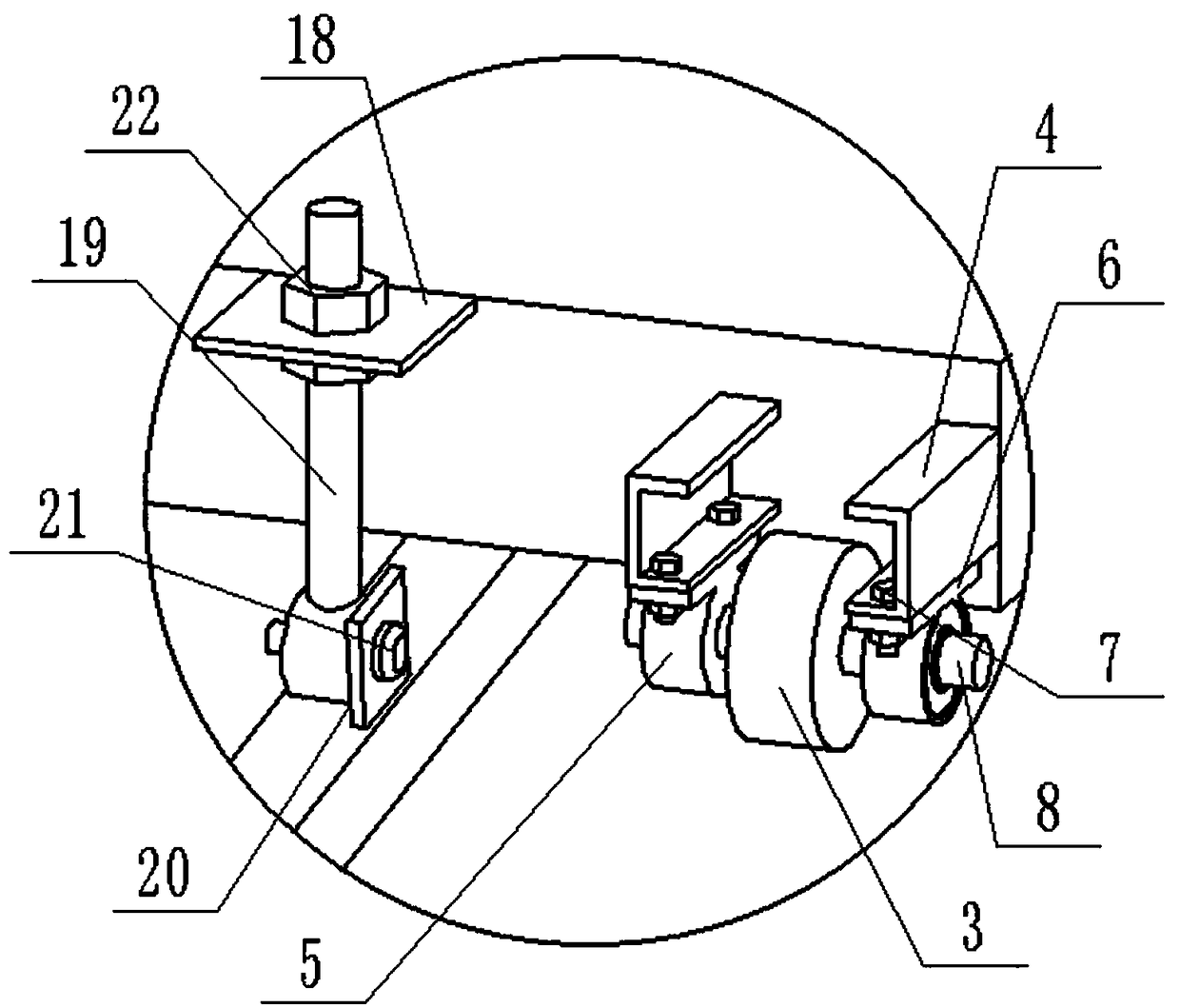

Water treatment gas floating slag scraper

ActiveCN106315729AImprove transmission efficiencyHigh transmission powerWater/sewage treatment by flotationBristleSlag

The invention discloses a water treatment gas floating slag scraper which comprises a slag scraper body, scraping bristles and wheels, wherein wheel shafts are arranged in the wheels; supporting frames are arranged above the wheels on the slag scraper body; a travel switch I is arranged on the supporting frames; a motor is arranged on the rear side of the slag scraper body; a chain wheel I is arranged on an output shaft of the motor; chain wheels II are arranged on the wheel shafts; the chain wheel I is connected with the chain wheels II through chains; a movable frame is arranged below the slag scraper body; the rear end of the movable frame is connected with the lower end surface of the slag scraper body; a long bolt is arranged between the front end of the slag scraper body and the movable frame; a connection frame is arranged at the front end of the movable frame; a connection plate III is arranged at the front end of the connection frame; the scraping bristles are located on the front end surface of the connection plate III; a cylinder is arranged on the front side of the slag scraper body; a connection plate V is arranged on the scraping bristles; a controller is arranged on the upper end surface of the slag scraper body; a hydraulic pump is arranged on the rear side of the controller. The water treatment gas floating slag scraper provided by the invention is simple in structure, good in slag scraping effect and convenient to operate.

Owner:SHANDONG PROVINCE WINSON NON WOVEN MATERIALS

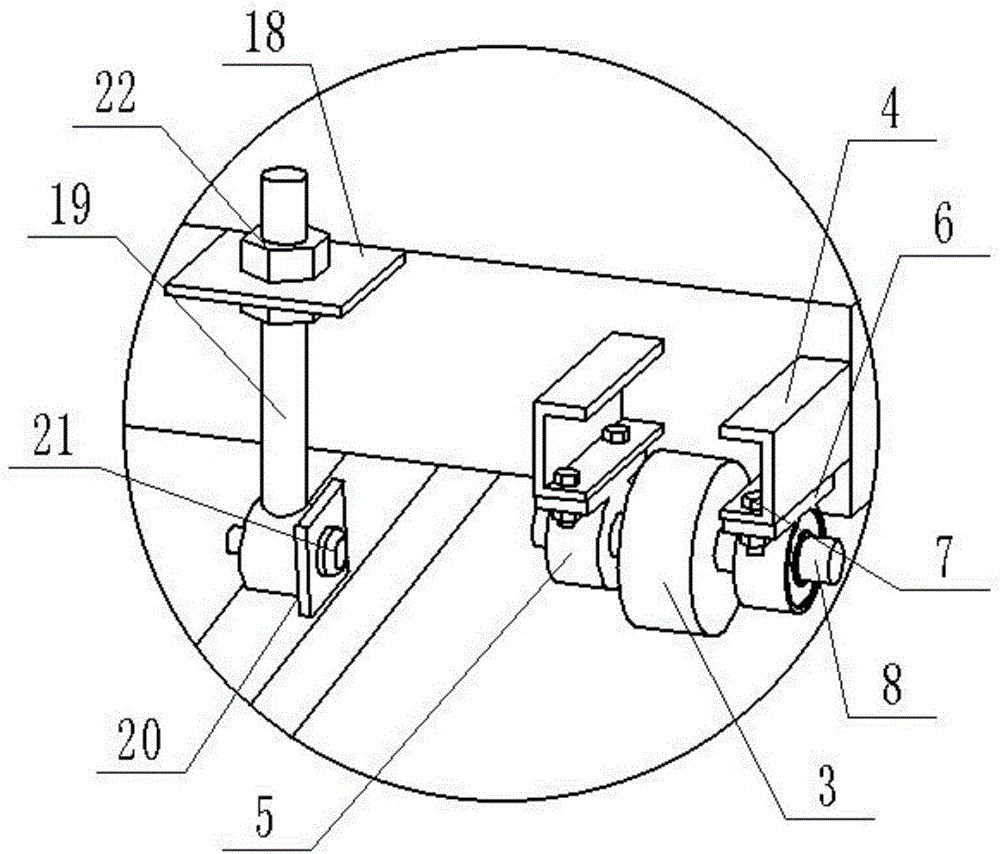

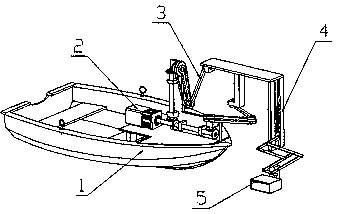

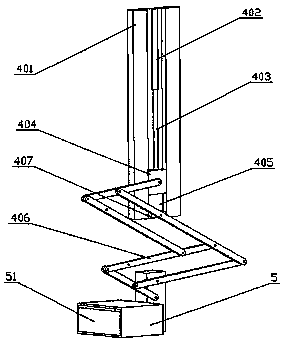

Sewage salvage device for energy storage power station reservoir

PendingCN109183761AEffective salvageMeet cleaning needsWater cleaningWaterborne vesselsPower stationEngineering

The invention discloses a sewage salvage device for an energy storage power station reservoir, and belongs to the technical field of energy storage power stations. According to the technical scheme, the sewage salvage device for the energy storage power station reservoir comprises a ship, a driving mechanism is arranged on the ship, the driving mechanism is connected with a horizontal movement mechanism, the horizontal movement mechanism is arranged on the upper portion of the ship, the horizontal movement mechanism is connected with a vertical adjusting mechanism, the horizontal movement mechanism drives the vertical adjusting mechanism to horizontally move, the vertical adjusting mechanism is arranged on one side of the ship, the bottom end of the vertical adjusting mechanism is connected with a cleaning box, and the vertical adjusting mechanism is used for adjusting the depth of the cleaning box entering the water surface of the reservoir. The technical scheme has the beneficial effects of being simple in structure, novel in design, high in practicability and convenient to use, floating garbage on the water surface of the energy storage power station reservoir can be effectivelyfished, the labor force is reduced, and the efficiency is improved.

Owner:STATE GRID CORP OF CHINA +2

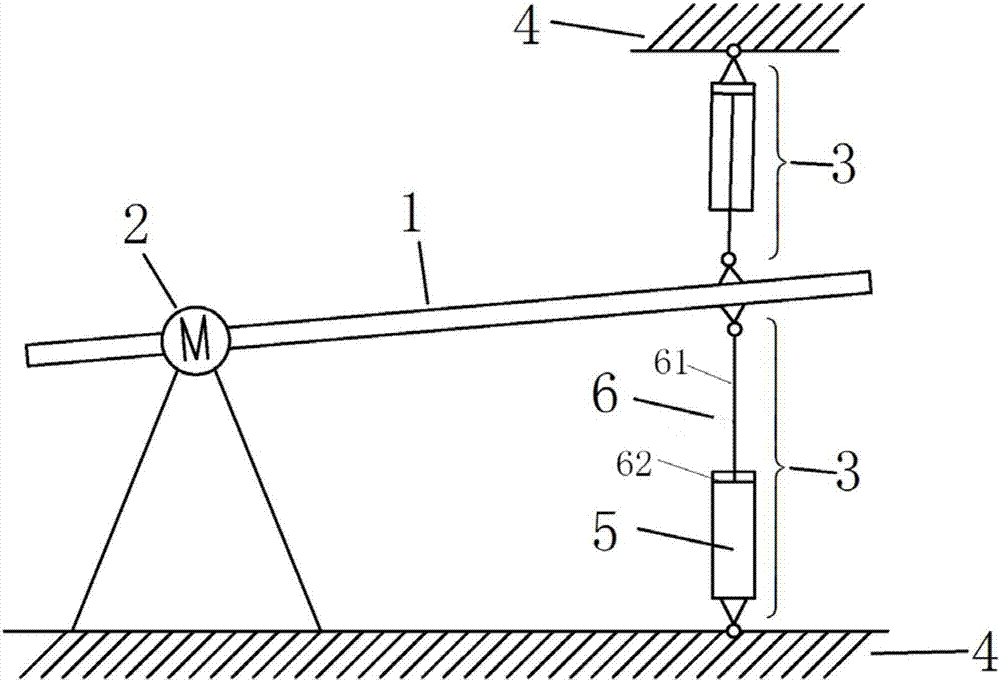

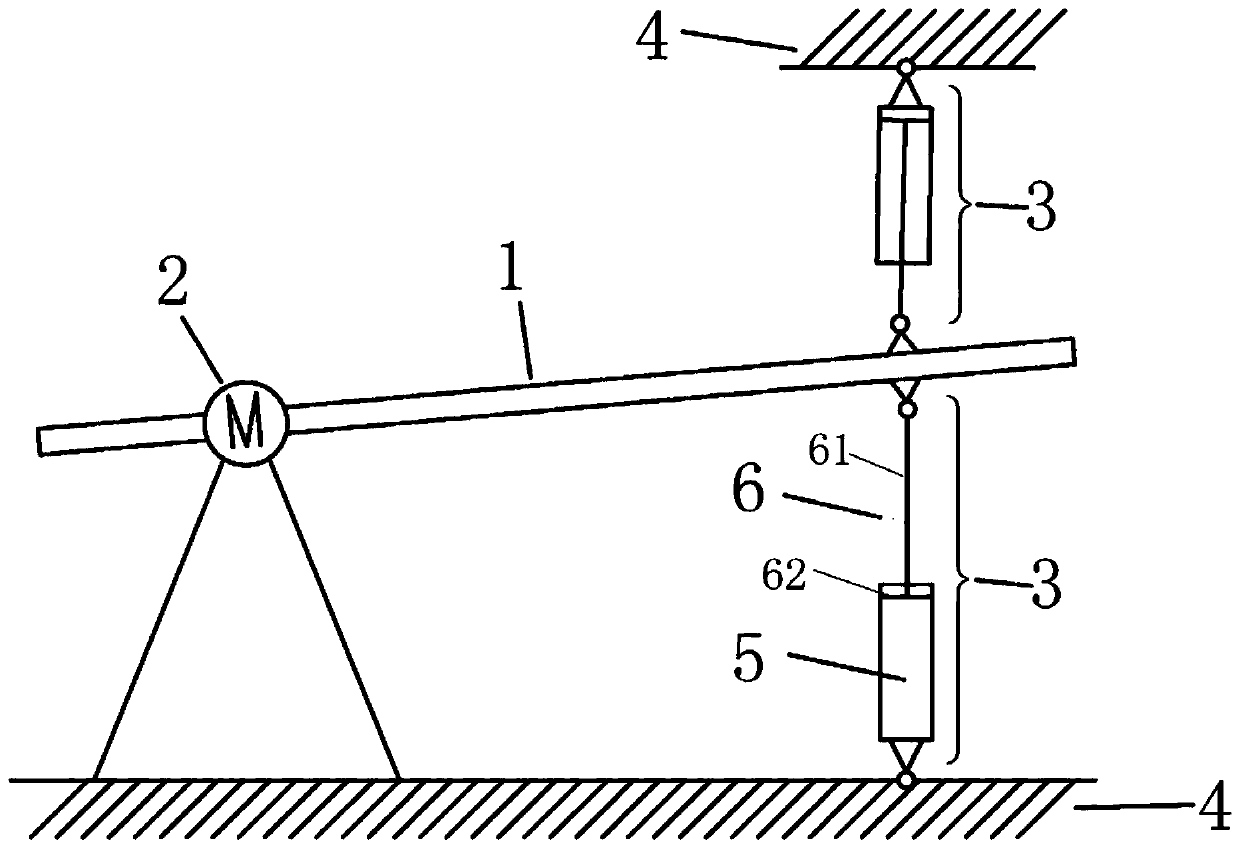

Driving device for reciprocating motion around shaft

InactiveCN107196454AReduce demandReduce operating energy consumptionMechanical energy handlingReciprocating motionMotion parameter

The invention discloses a driving device for reciprocating motion around a shaft. The driving device comprises a driving motor for outputting a torque period and with adjustable curve, wherein the driving motor is used for outputting periodic torque driving load; one or more parameter adjustable energy storages for absorbing the energy in the load deceleration and outputting the energy in the load acceleration; a load base with adjustable reciprocating motion period, adjustable reciprocating motion zero position and adjustable reciprocating motion angle amplitude. The driving device disclosed by the invention is used for driving the load to perform the reciprocating motion around the shaft, a rotating shaft is directly driven by using a moment motor, a mechanical transmission device is cancelled, and the energy storage is provided; the driving device disclosed by the invention has the advantages of being adjustable in motion parameter, simple in transmission mechanism, convenient in analysis and computation method, low in energy consumption, high in reliability, low in noise and low in cost.

Owner:南京智真电子科技股份有限公司

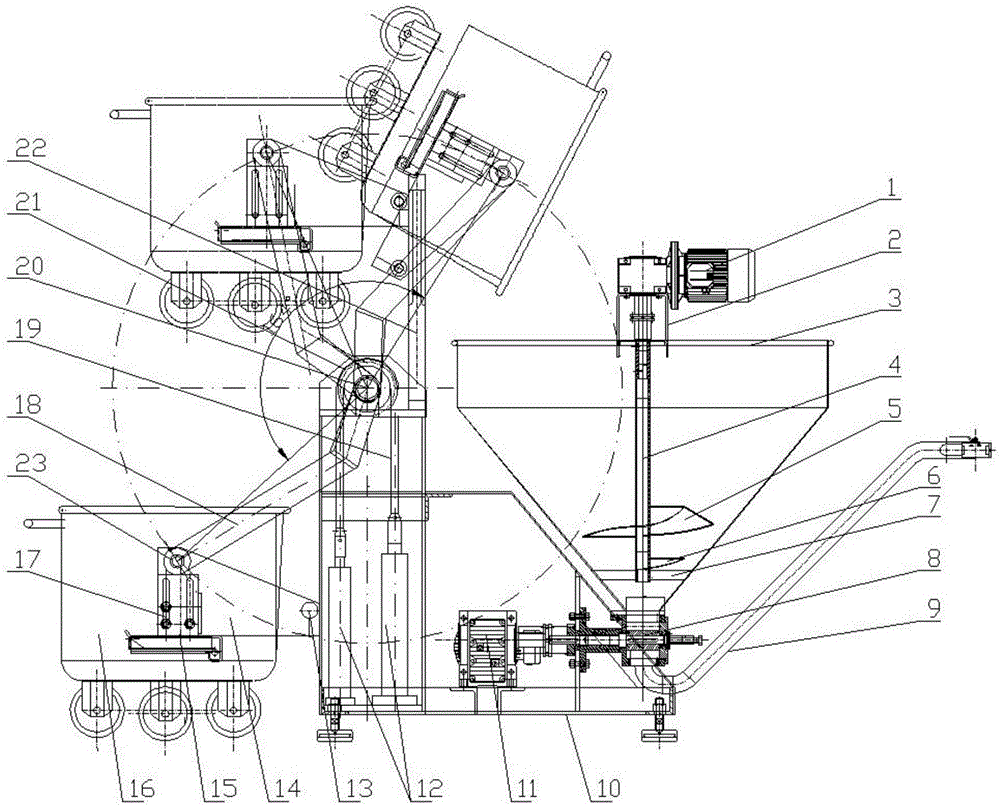

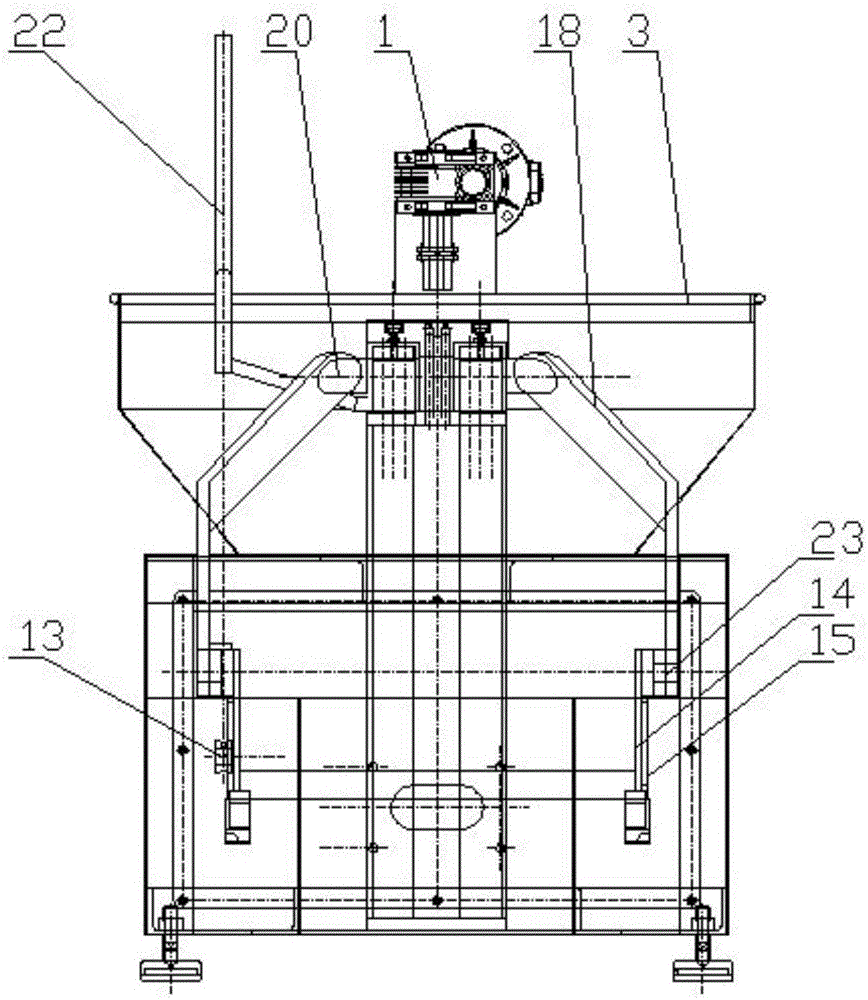

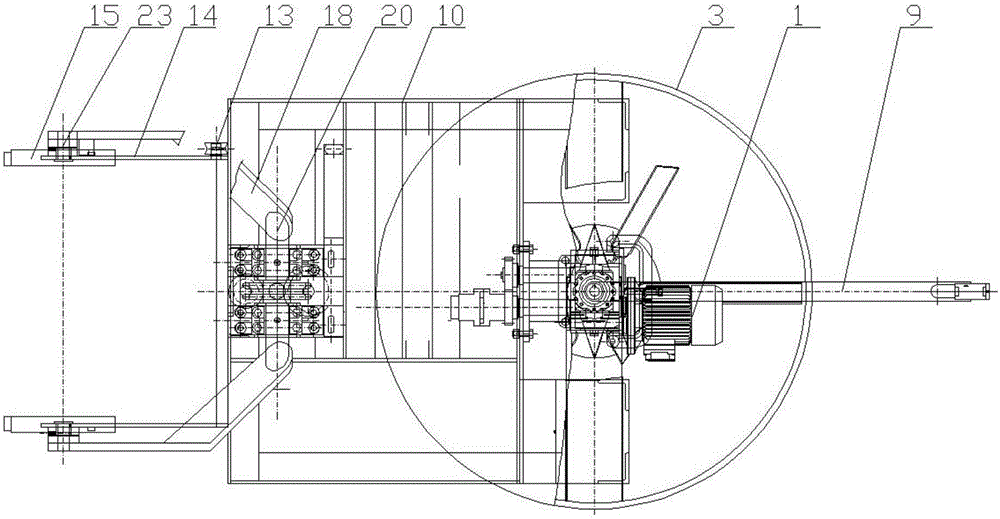

Novel filling machine

ActiveCN107434055APrevent solidificationEasy to disassembleLiquid materialHydraulic cylinderGear pump

The invention relates to a novel filling machine. The novel filling machine comprises a rack and a material storage hopper mounted on the rack, an outlet of the material storage hopper is connected with a discharging pipe, and double gears mutually meshed with each other are mounted between the outlet of the material storage hopper and the discharging pipe and driven by a gear pump; a stirring device is mounted at a feeding opening of the material storage hopper, and a feeding device is mounted on the rack at one side of the material storage hopper. According to the novel filling machine, the stirring device is mounted on the material storage hopper, food is slowly stirred in the filling process, and tofu and other food easy to solidify are prevented from being solidified. The feeding device is driven by hydraulic cylinders, and the rotation of sprockets is achieved through the reciprocating movement of pistons, so that a rotating shaft is driven to rotate, the rotation of a swing arm is achieved, and the filling machine runs stably and reliably.

Owner:TIANJIN YINGDAHUA FOOD MACHINERY MFG

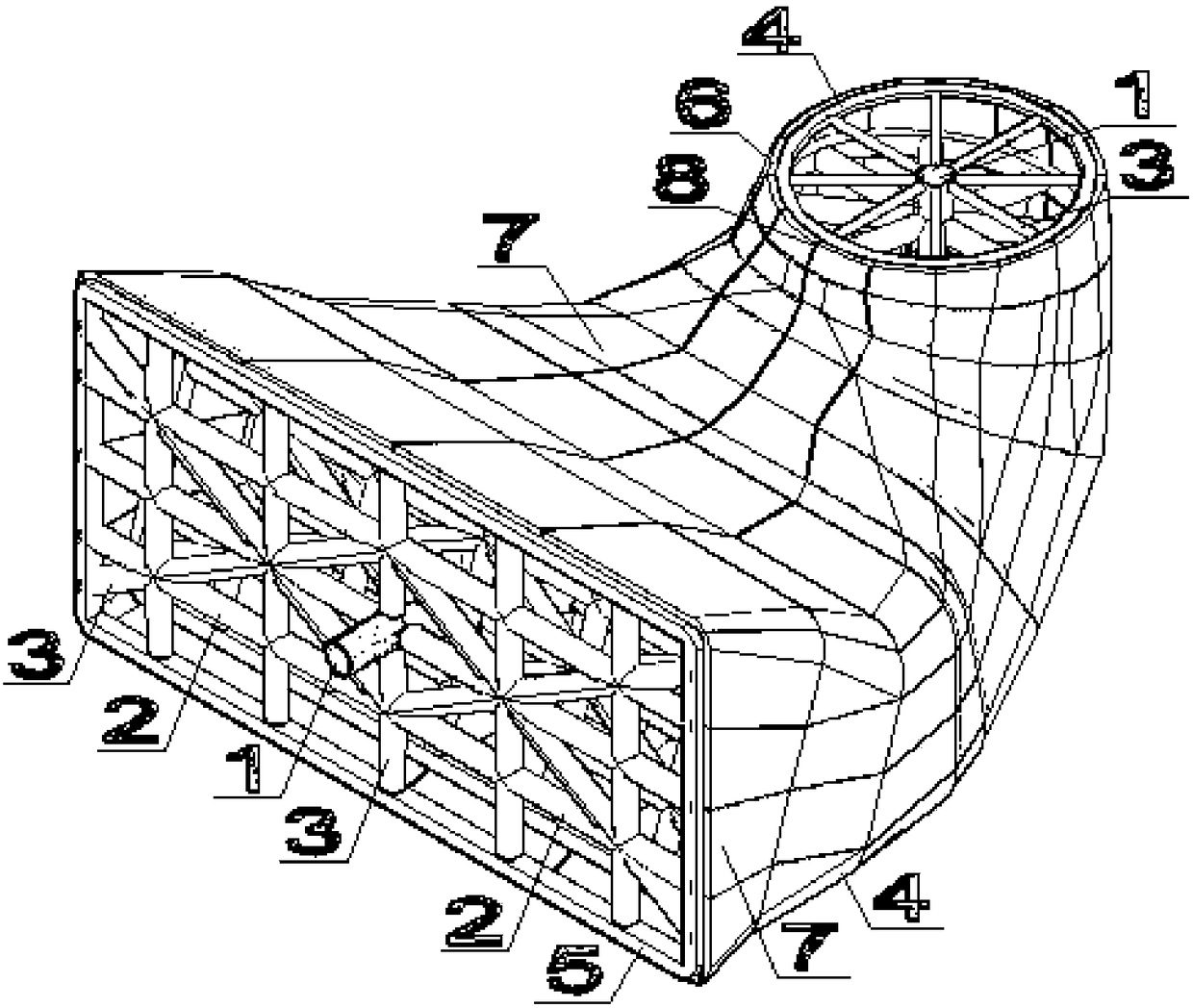

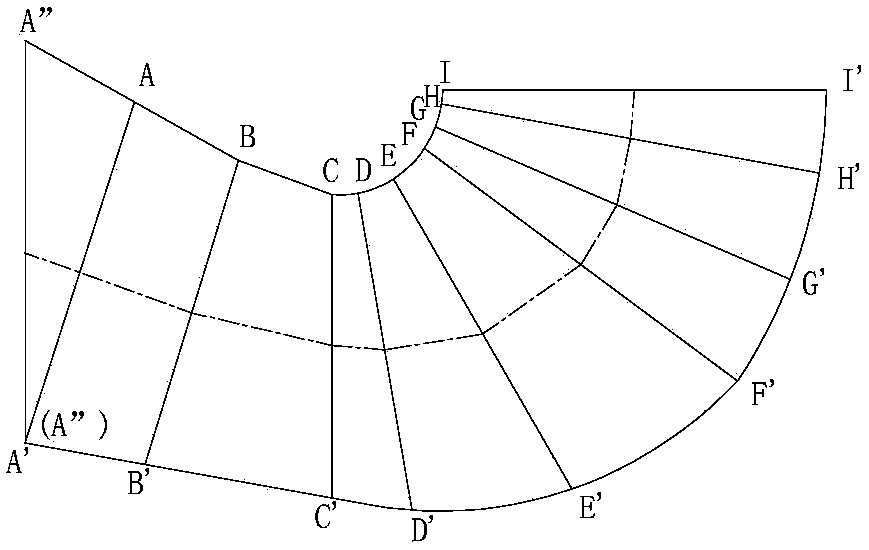

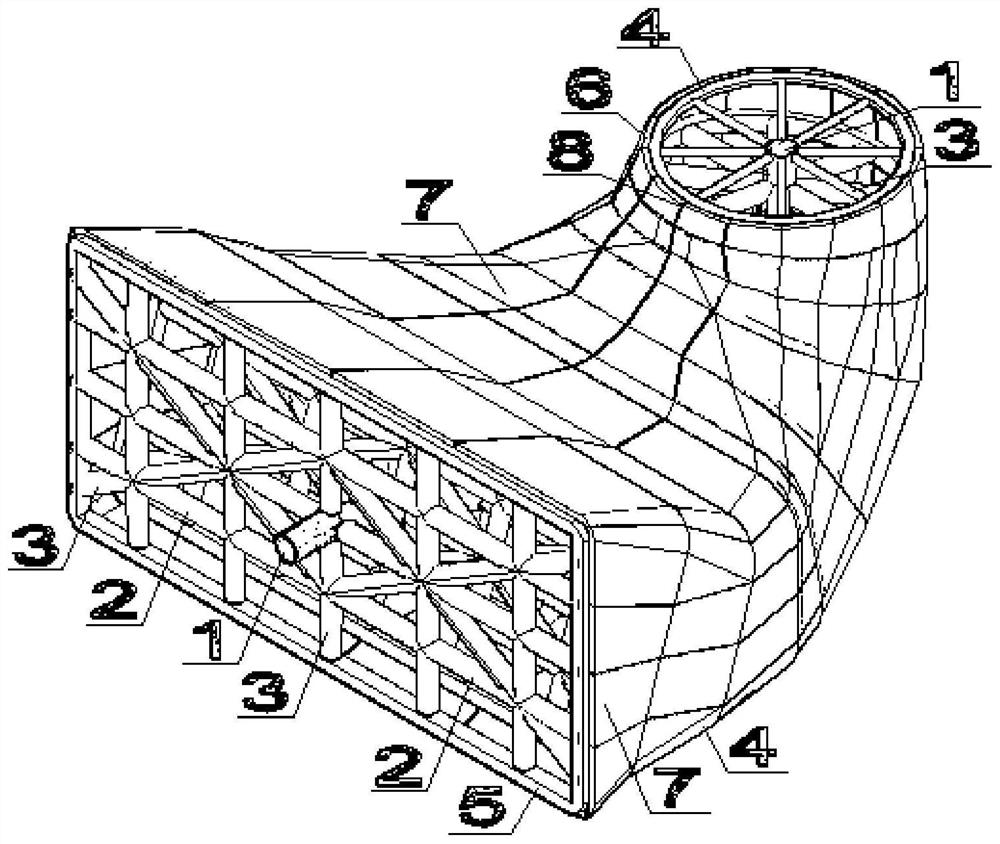

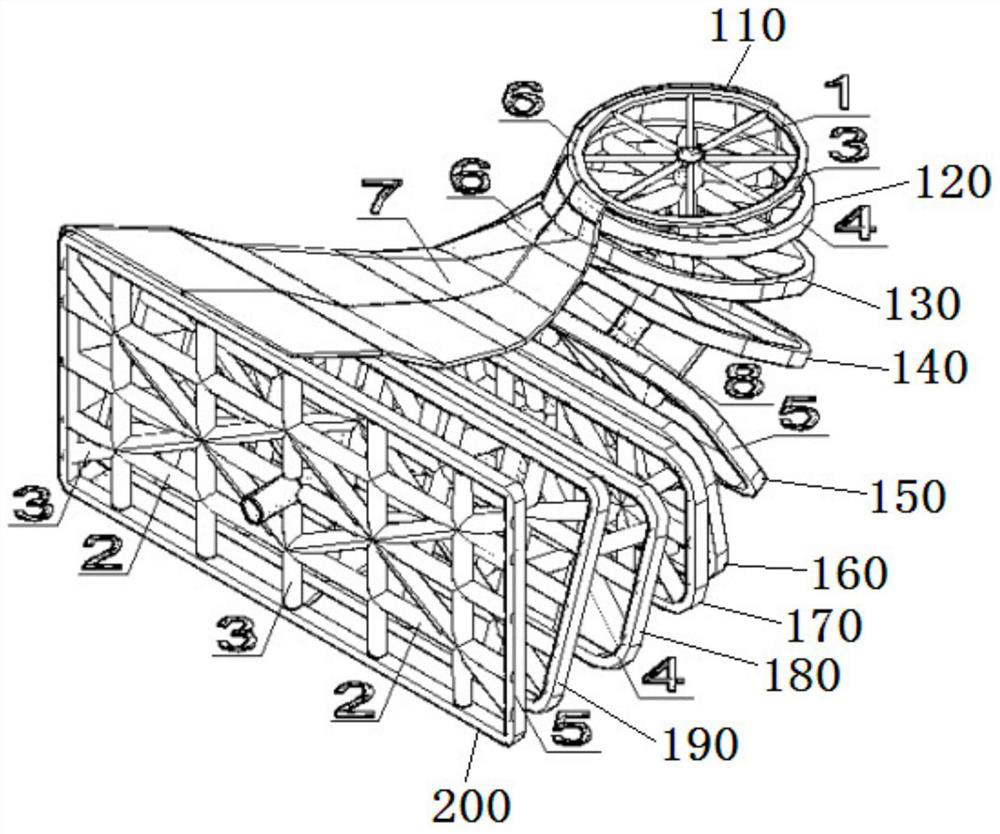

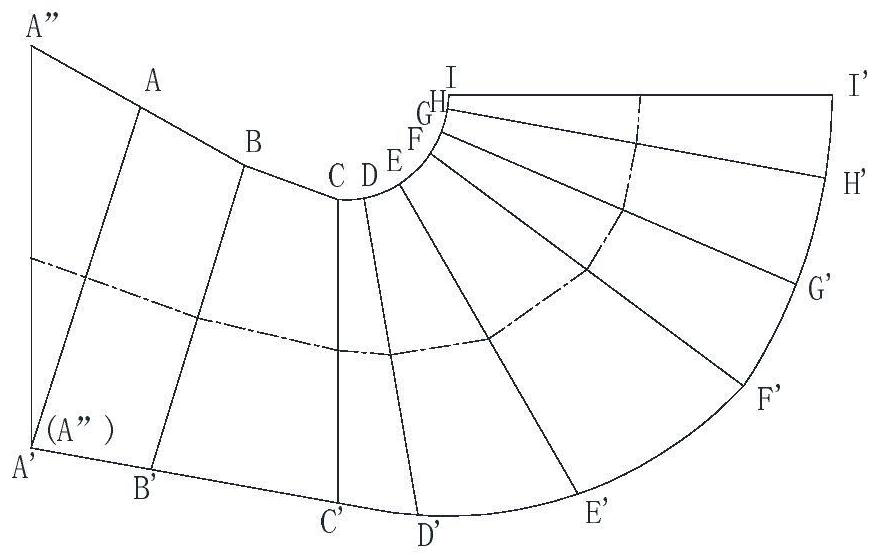

Reusable hydraulic combined special-shaped steel template and disassembly method thereof

ActiveCN108560905ASmooth motionSimple structureForms/shuttering/falseworksHydraulic cylinderPulp and paper industry

The invention discloses a reusable hydraulic combined special-shaped steel template and disassembly method thereof. The steel template comprises an arc section bent frame, a straight section bent frame, a hydraulic main pipe, a hydraulic oil cylinder, a circular arc panel and a plane panel. The hydraulic main pipe is the same as the bending shape of the elbow section of the pump station flow channel, and the hydraulic main pipe penetrates respectively straight through the center of the arc section bent frame and the straight section bent frame; the hydraulic oil cylinder comprises a radial hydraulic oil cylinder, a central straight hydraulic oil cylinder, a lateral hydraulic oil cylinder and an oblique hydraulic oil cylinder; each hydraulic cylinder is provided with a metering valve. The Hydraulic combined special-shaped steel template capable of being repeatedly used and disassembling method thereof ingeniously uses hydraulic oil cylinder as the support and shaping structure of the elbow section of the pump station flow passage , and corrects the deformation of the arc section bent frame, the straight section bent frame, the circular arc panel and the plane panel to ensure the position accuracy of the template by driving the hydraulic oil cylinder through the hydraulic oil to adjust the corresponding stroke or length, , the steel die can be automatically put up or disassembledafter the concrete takes shape, so that the steel template can be repeatedly used and the positioning accuracy is high.

Owner:CHINA THREE GORGES UNIV

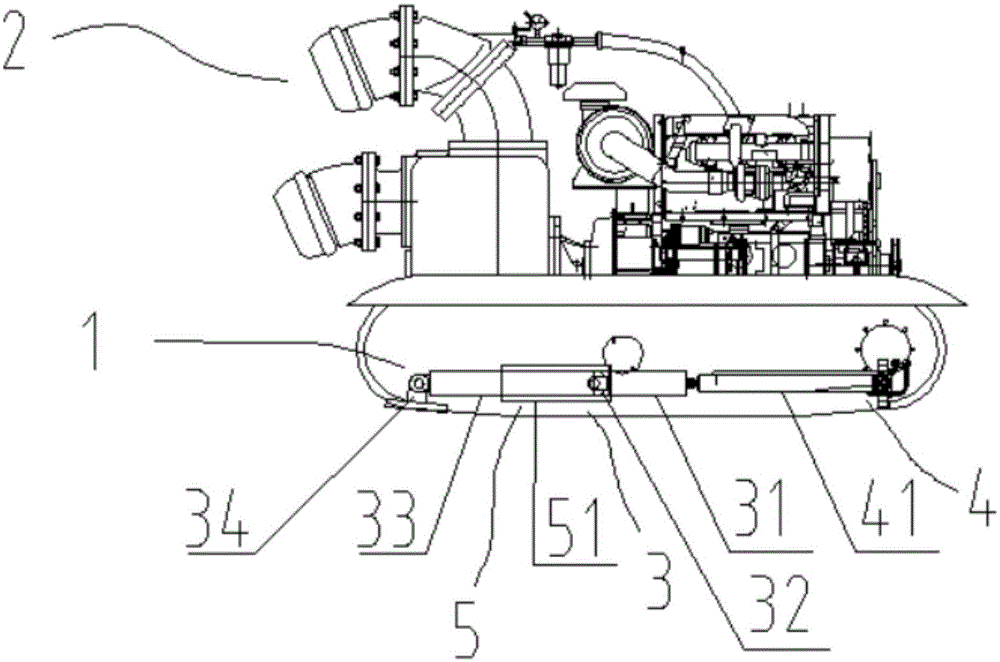

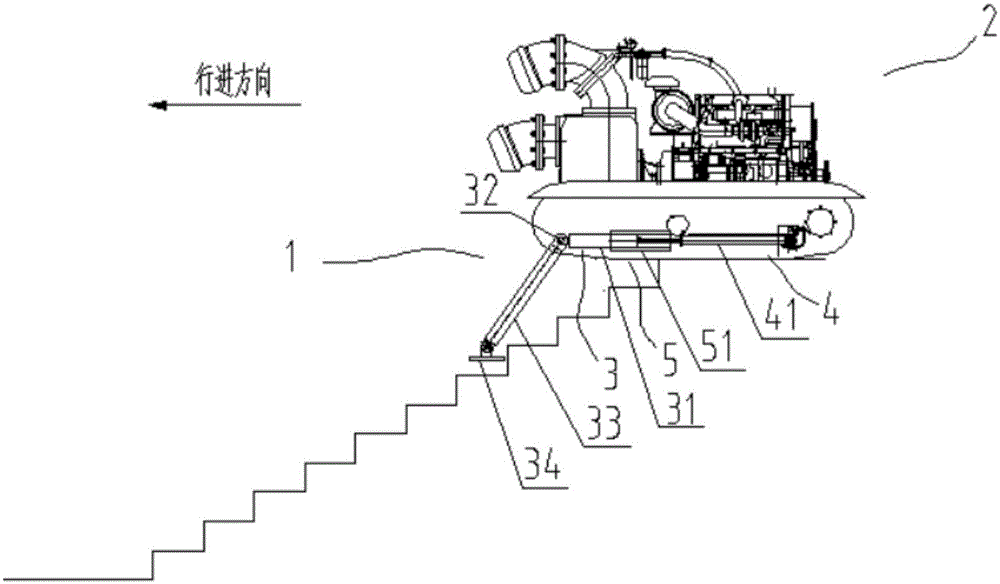

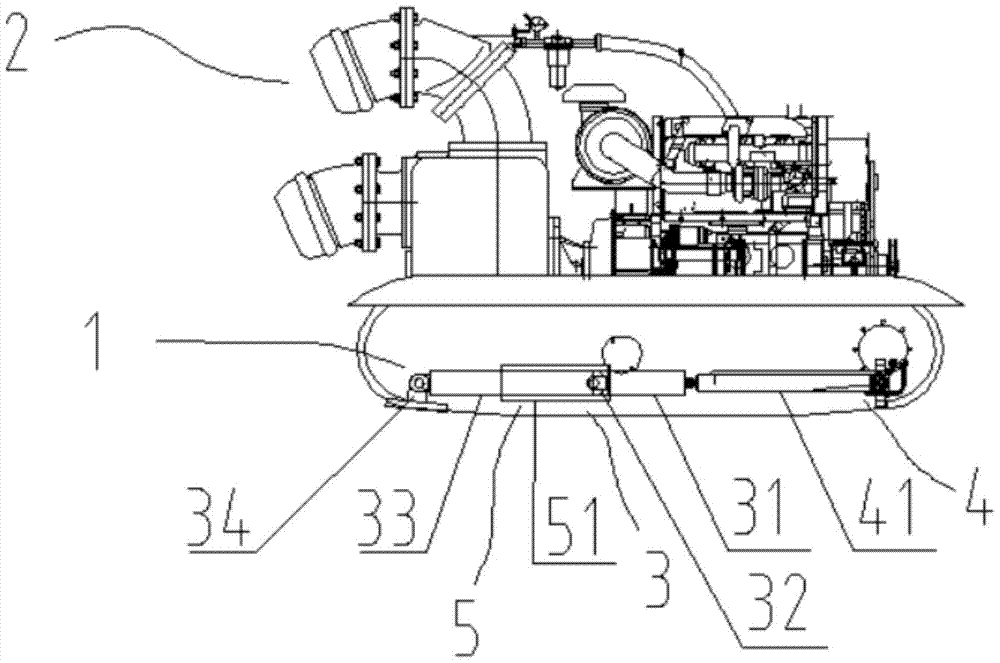

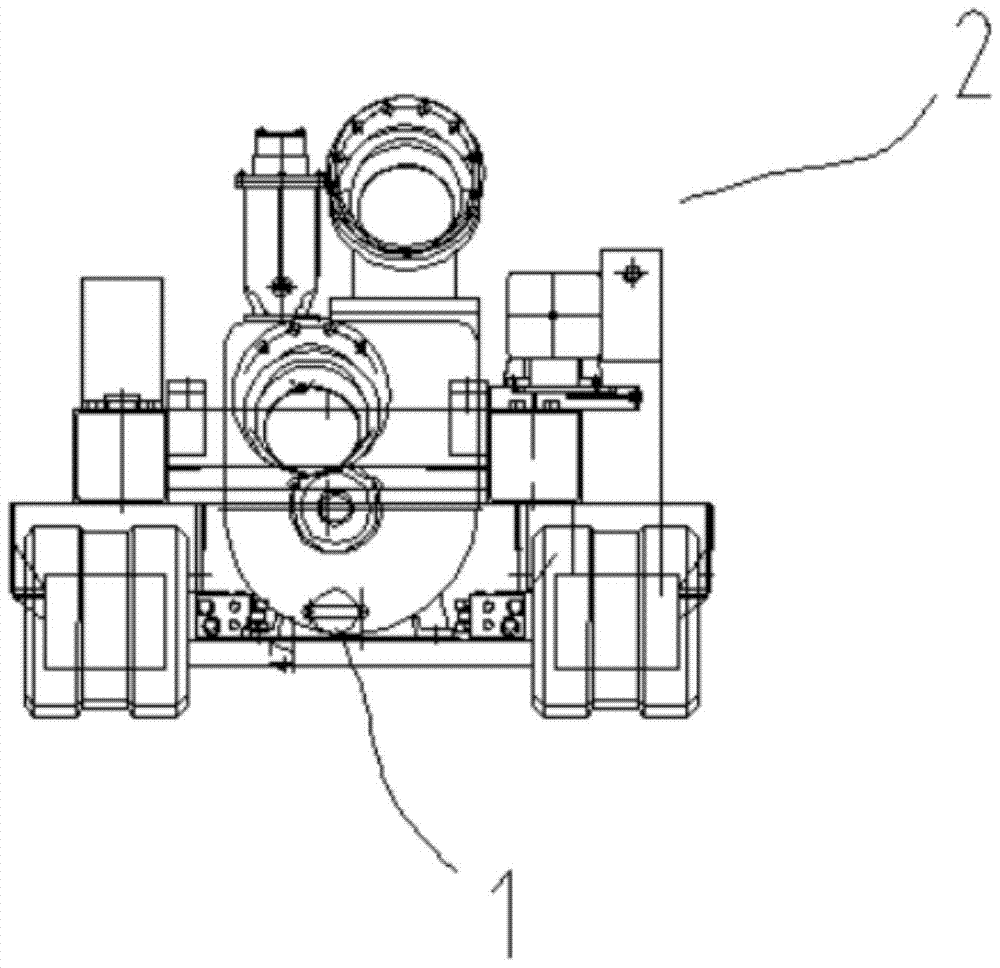

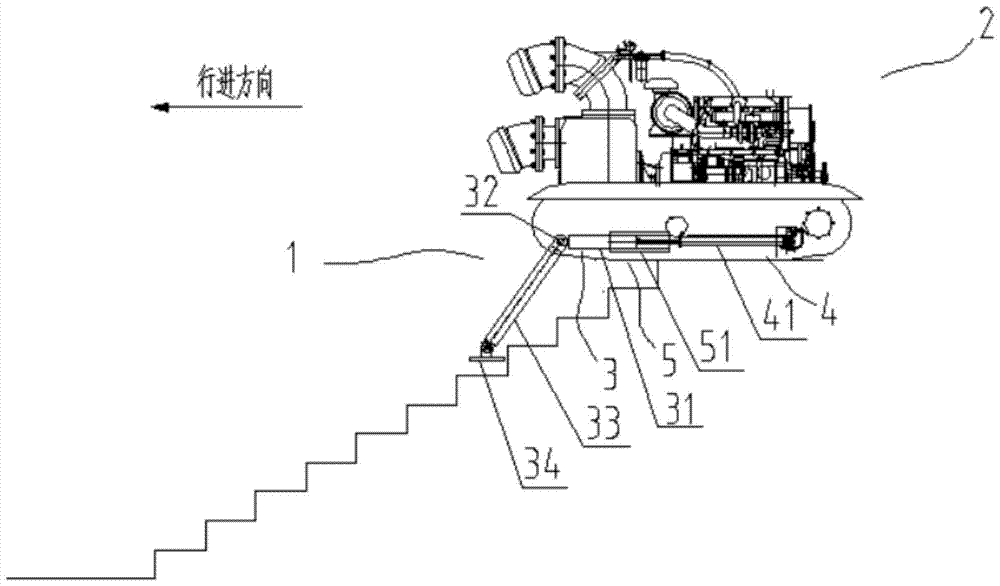

Auxiliary mechanism for assisting caterpillar operation device to walk downstairs

ActiveCN105151142ASimple structureWork reliablyEndless track vehiclesElectrical and Electronics engineeringWalking downstairs

The invention provides an auxiliary mechanism for assisting a caterpillar operation device to walk downstairs. The auxiliary mechanism comprises a supporting component which can extend to a position obliquely below the advancing direction of a caterpillar operation device body, wherein the supporting component has the effects of supporting and buffering when the caterpillar operation device walks downstairs, so that the phenomenon that because the caterpillar operation device suddenly accelerates to advance obliquely downwards, the caterpillar operation device turns over is avoided. The auxiliary mechanism is simple in structure, small in size, low in cost, reliable to operate and convenient to use, and when the auxiliary mechanism for assisting the caterpillar operation device to walk downstairs is not used, and walking and normal operation of the caterpillar operation device are not influenced; the auxiliary mechanism has a wide market prospect and a wide development space, and has a high popularization value.

Owner:FUJIAN QIAOLONG EMERGENCY EQUIP CO LTD

A reusable hydraulic combined special-shaped steel formwork and disassembly method

ActiveCN108560905BSmooth motionSimple structureForms/shuttering/falseworksHydraulic cylinderHydraulic ram

The invention discloses a reusable hydraulic combined special-shaped steel formwork and a dismantling method, which includes a circular arc section bent frame, a straight line section bent frame, a hydraulic main pipe, a hydraulic oil cylinder, an arc panel and a plane panel; the hydraulic main pipe and the pumping station flow The bending shape of the elbow section of the road bend is the same, and the hydraulic main pipe passes through the center of the curved frame of the arc section and the bent frame of the straight section; the hydraulic cylinders include radial hydraulic cylinders, central linear hydraulic cylinders, lateral hydraulic cylinders and oblique hydraulic cylinders. Cylinders; each hydraulic cylinder is equipped with metering valves. The present invention skillfully utilizes the hydraulic cylinder as the supporting and shaping structure of the elbow section of the flow path of the pump station, and the hydraulic oil is used to push the hydraulic cylinder to adjust the corresponding stroke or length, so as to correct the arc section bent frame, straight line section bent frame, arc panel, The deformation of the plane panel ensures the position accuracy of the formwork. It can not only set up the steel formwork automatically, but also disassemble the steel formwork after the concrete is formed, so that the steel formwork can be used repeatedly and has high positioning accuracy.

Owner:CHINA THREE GORGES UNIV

Friction planetary reducer

InactiveCN104061295BLarge transmission ratioNo transmission gapGearing detailsFriction gearingsReducerTransmission ratio

The invention provides a friction planetary reducer, belongs to the technical field of machineries, and solves the problem that the conventional gear planetary reducer is small in transmission ratio. The friction planetary reducer comprises a cylindrical shell, an input end cover and an output end cover, wherein the input end cover and the output end cover are arranged at two ends of the shell respectively; an input shaft and an output shaft are arranged in the shell; the middle of the input shaft is provided with an annular step A positioned in the shell; the output end of the input shaft is provided with an annular step B positioned in the shell; a flexible cylinder, with which the input shaft is sleeved, is arranged in the shell; a plurality of fixed flexible gears coaxial with the input shaft are arranged between the flexible cylinder and the annular step A; a rotating shaft A, one end of which is fixed on the input end cover, is arranged in each fixed flexible gear; a plurality of planetary flexible gears coaxial with the input shaft are arranged between the flexible cylinder and the annular step B; a rotating shaft B, one end of which is fixed on the output shaft, is arranged in each planetary flexible gear. The friction planetary reducer has the advantages of being large in transmission ratio, simple in structure, and the like.

Owner:温岭市天工工量刃具科技服务中心有限公司

Arc swinging device applied to automatic metal welding

The invention relates to an arc swinging device applied to automatic metal welding. The arc swinging device comprises a welding gun, an arc swinging crank connecting rod mechanism and a welding gun clamping and weld width adjusting mechanism, wherein the arc swinging crank connecting rod mechanism comprises a base plate, a direct-current motor, an eccentric gear, a connecting rod and a swinging guide plate; the direct-current motor is connected with the base plate; the output shaft of the direct-current motor is connected with one side of the eccentric gear; two sides of the connecting rod are respectively hinged with the eccentric gear and the swinging guide plate; the swinging guide plate is fixed on the base plate; the welding gun clamping and weld width adjusting mechanism comprises a sliding plate and a clamping block; the gun stem of the welding gun is installed between the sliding plate and the clamping block and can be axially adjusted; the sliding plate is adjustably installed on the swinging guide plate; and weld width indication lines are arranged on the swinging guide plate and the sliding plate. The arc swinging device has the characteristics of being reasonable and simple in structure, convenient to repair, low in manufacturing cost and easy to control.

Owner:CHANGZHOU JIAZHUO SPECIAL VEHICLES +1

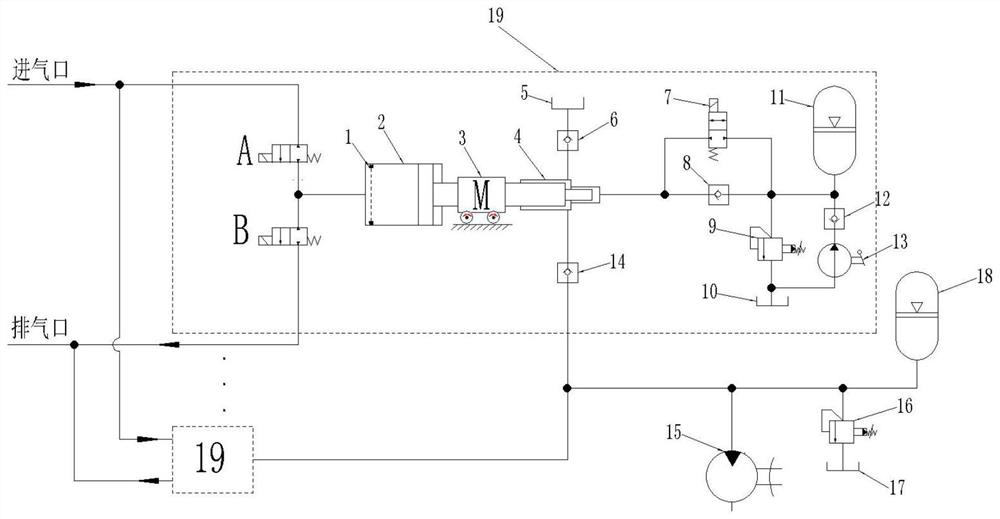

Free piston expansion type hydraulic power output system with balance weight mechanism

PendingCN113153867ASmooth movementSports EfficientServomotor componentsAccumulator installationsEnergy recoveryControl theory

The invention discloses a free piston expansion type hydraulic power output system with a balance weight mechanism. The free piston expansion type hydraulic power output system comprises an air inlet pipeline, an exhaust pipeline, an energy conversion unit and an energy output unit. The energy conversion unit comprises a first oil tank, a second oil tank, a free piston expansion machine, a plunger cylinder and a balance weight mechanism. An expansion cavity of the free piston expansion machine is connected with a switch valve A and a switch valve B which are connected in parallel and connected with an air inlet pipeline and an exhaust pipeline correspondingly, and a working cavity of the plunger cylinder is connected with a first branch and a second branch. The first branch is provided with a first one-way valve and a first oil tank, the second branch is provided with a second one-way valve, a third one-way valve, a second energy accumulator, a second safety valve, a manual pump and a second oil tank, and the two ends of the second one-way valve are connected with a two-position two-way electromagnetic valve in parallel. The energy output unit comprises a one-way quantitative hydraulic motor, a third oil tank, a first energy accumulator and a first safety valve. The free piston expansion type hydraulic power output system is simple in structure, low in manufacturing cost, suitable for two-phase flow and variable working condition working environments and high in energy recovery efficiency.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

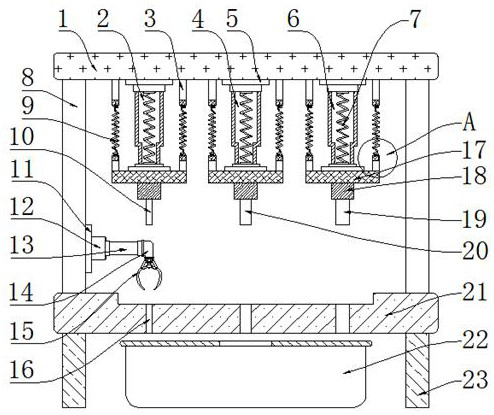

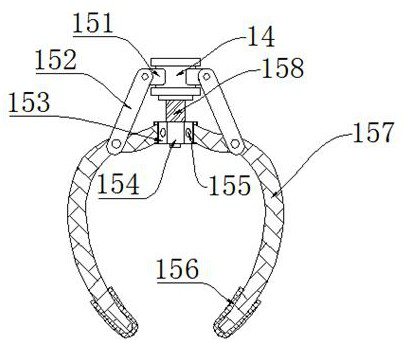

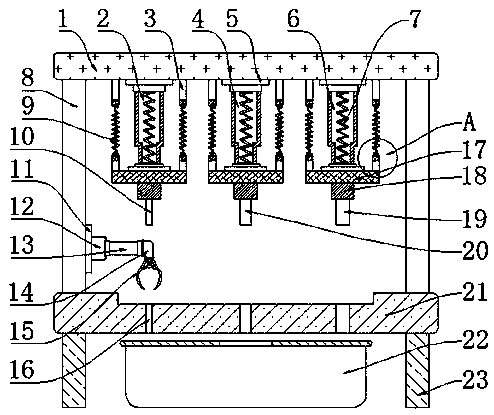

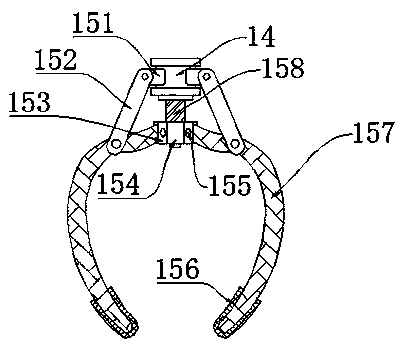

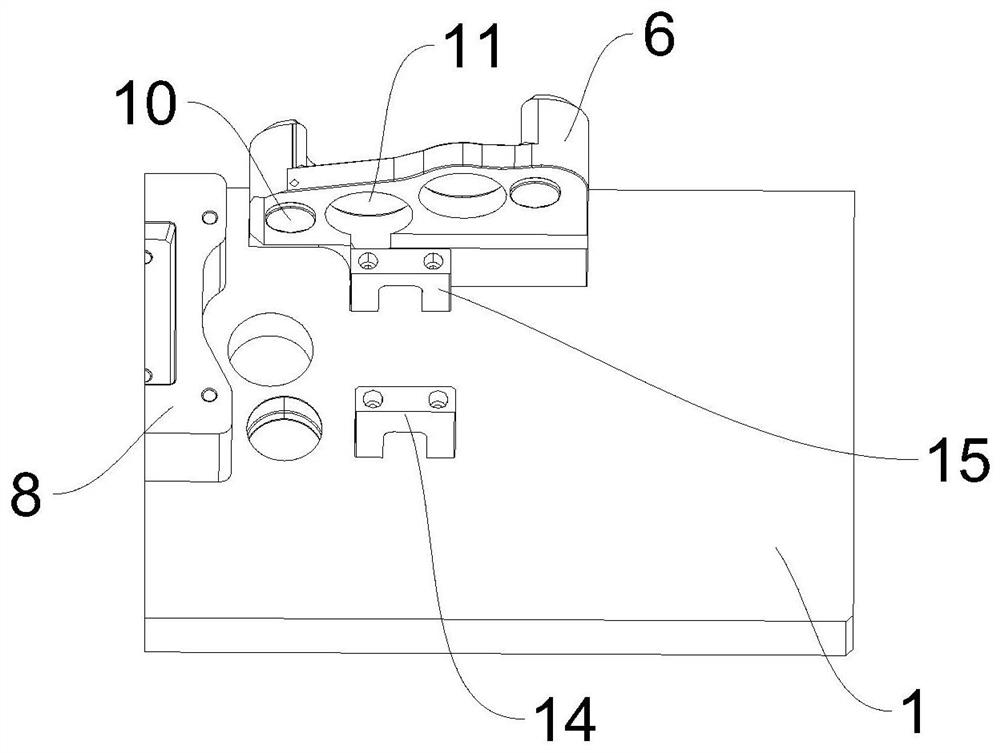

A stamping device for automotive electronic parts

ActiveCN109290423BReduce work intensityReduce processing timeMetal-working feeding devicesPositioning devicesStructural engineeringElectronic component

The invention discloses a stamping device for automobile electronic components. The stamping device comprises an operating platform. Mounting plates are arranged at the lower end of a top plate. A first piston cylinder, a second piston cylinder and a third piston cylinder are arranged at the lower ends of the three mounting plates correspondingly. Piston rods are arranged inside the first piston cylinder, the second piston cylinder and the third piston cylinder correspondingly. A stamping rod is mounted at the lower end of each stamping plate. A first stamping head, a second stamping head anda third stamping head are arranged at the lower ends of the stamping rods. A mounting bracket is arranged at the other side of a hydraulic extending-and-contracting rod. A component clamp is mounted at the lower end of the mounting bracket and provided with a sliding rotating shaft seat. Support pillars are mounted at the bottom end of the operating platform. A containing box is arranged below theoperating platform. By means of the stamping device, the automobile electronic components of different specifications can be stamped at the same time and gripped through the component clamp; and theelectronic components are prevented from being damaged.

Owner:刘兆

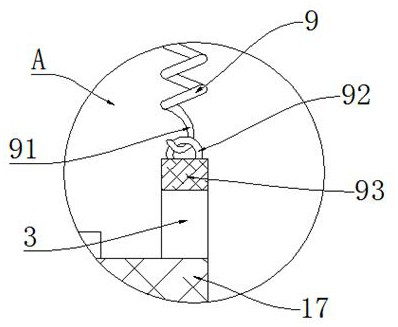

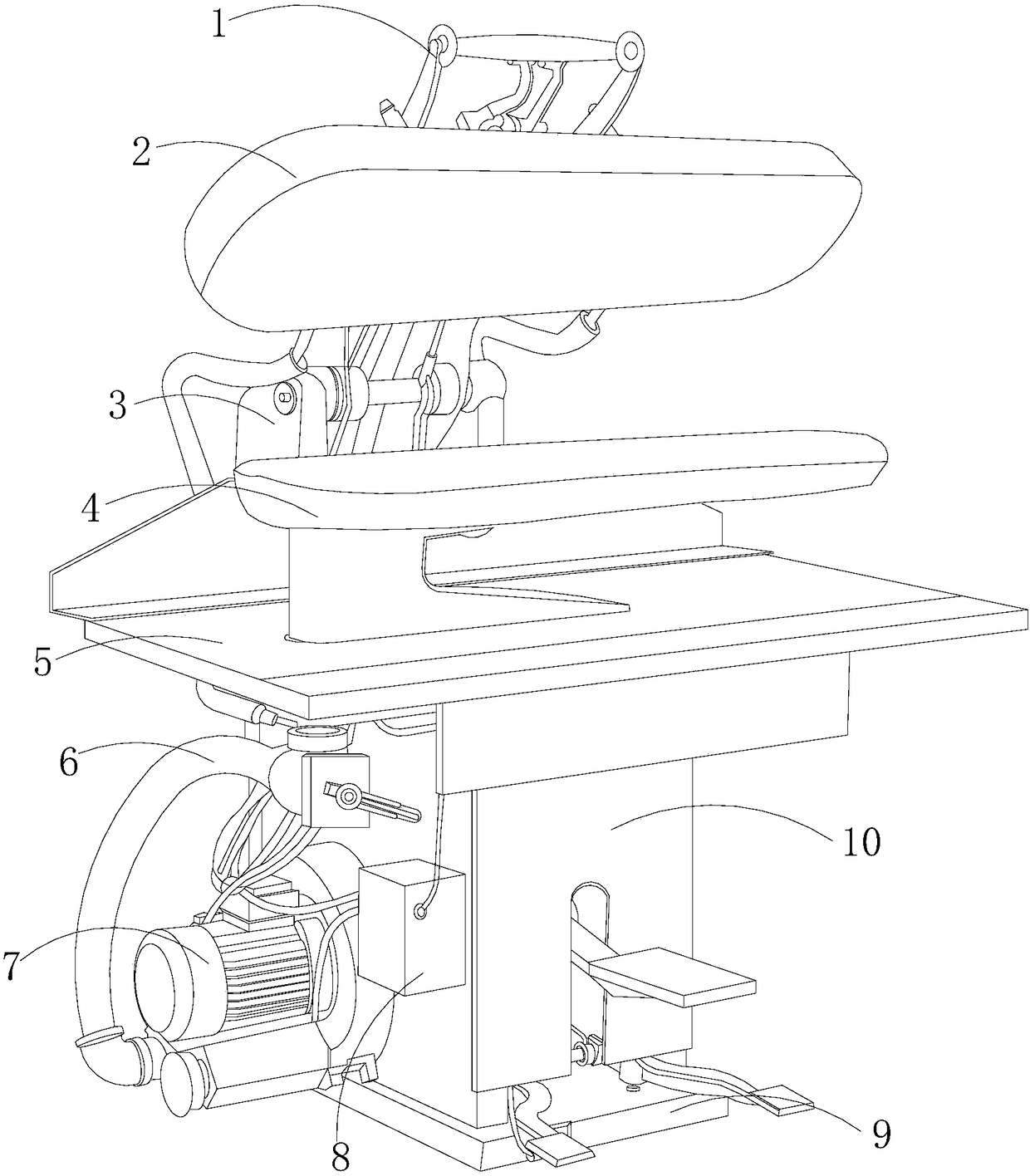

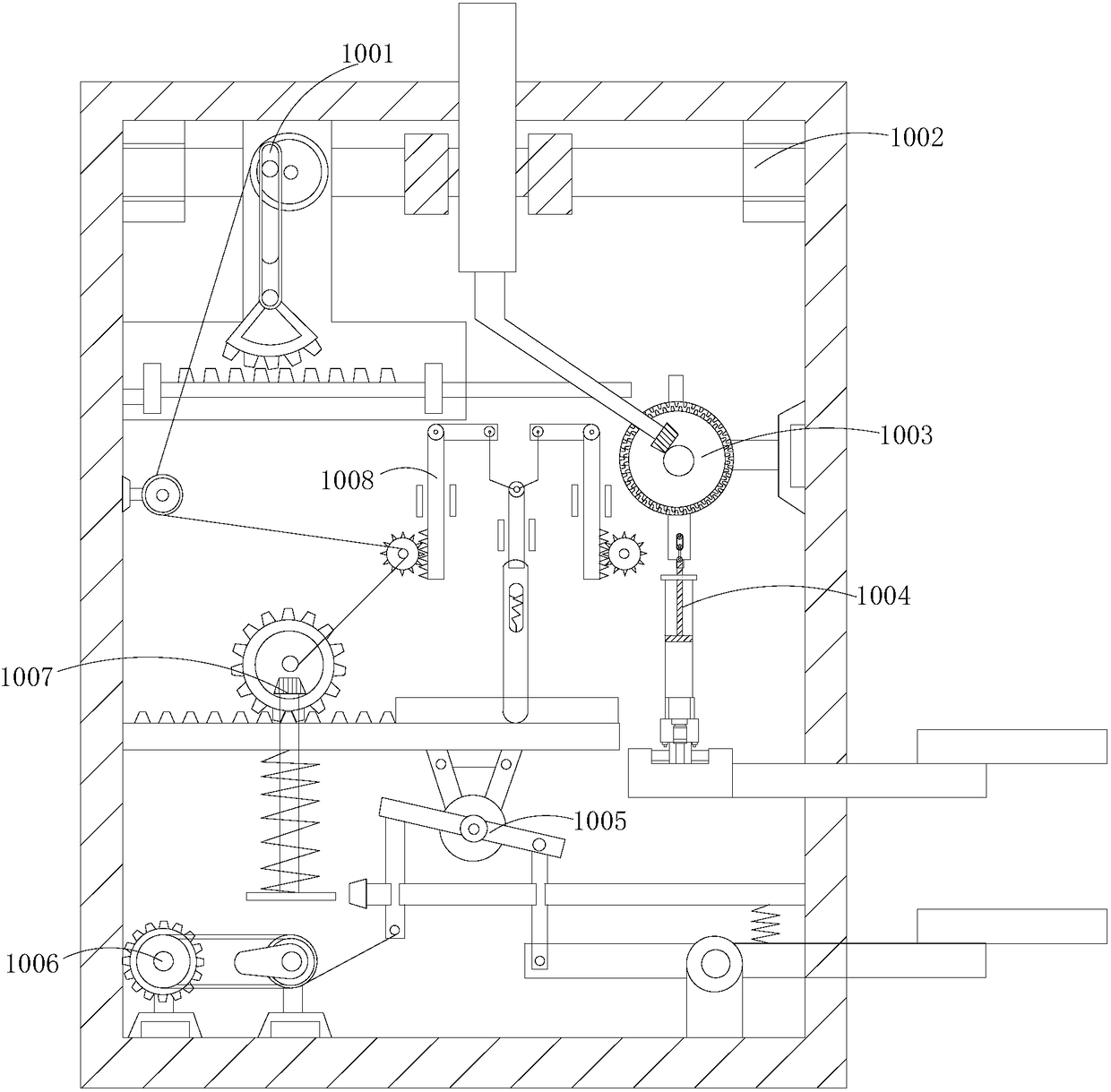

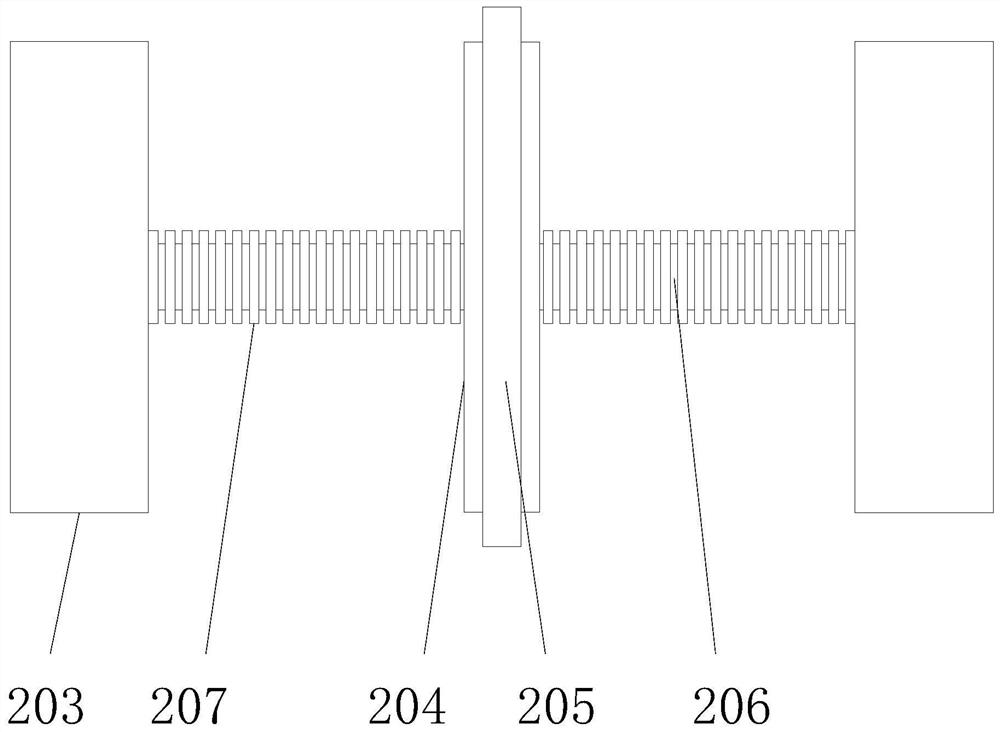

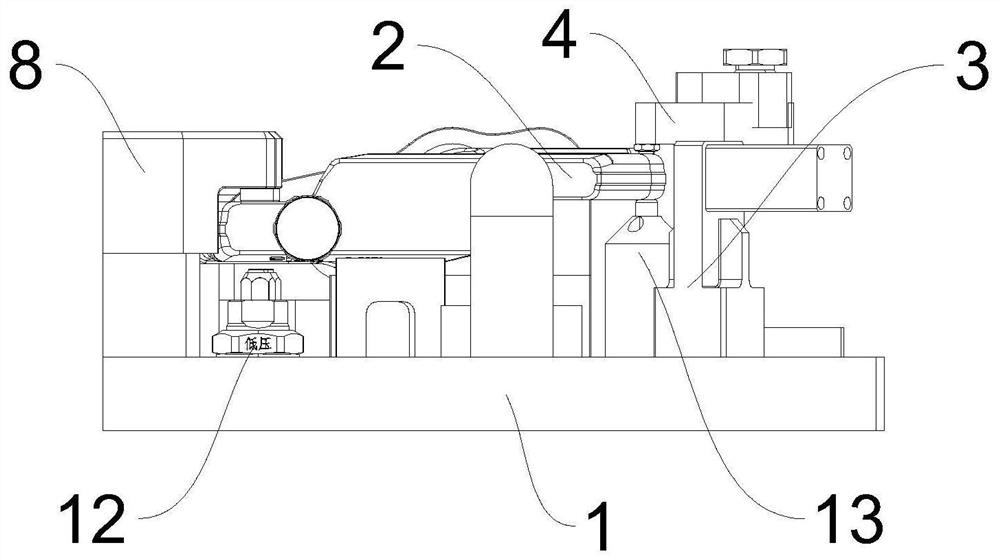

Automatic leveling equipment for cloth ironing

InactiveCN108517670AHigh rhythm efficiencyNo transmission gapIroning apparatusTextiles and paperReciprocating motionEngineering

The invention discloses automatic leveling equipment for cloth ironing. The mechanism comprises a pushing mechanism, an ironing and leveling block, an ironing and leveling block mounting seat, a clothplacing table, a mounting disc, a connecting water pipe, a motor, an electric control box, a chassis and a crate, wherein the ironing and leveling block is buckled and fixed to the ironing and leveling block mounting seat; the pushing mechanism is mechanically connected to the middle part of the back of the ironing and leveling block; the cloth placing table is horizontally fixed on the mountingdisc; the connecting water pipe is connected between the motor and the crate; the electric control box clings to and is fixed to the left side of the crate; the crate is vertically fixed to the chassis; the mounting disc is welded and fixed to the top of the crate; and the ironing and leveling block is symmetrical to the top of the cloth placing table. The pushing mechanism reciprocates through ahydraulic cylinder, so that a reducing device is cancelled. No transmission gap is available, so that the movement is steady and the ironing and leveling efficiency is improved greatly, and the ironing and leveling quality is improved greatly.

Owner:HUZHOU LINGHU ZHONGZHAO JINHUI SILK WEAVING FACTORY

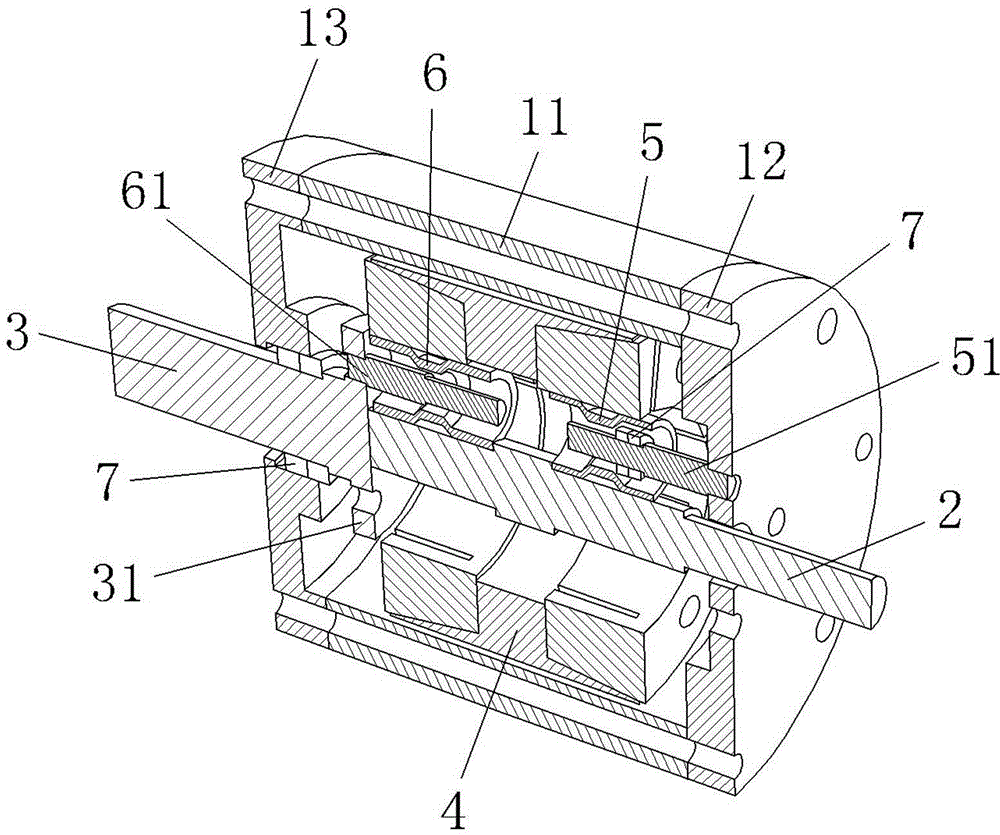

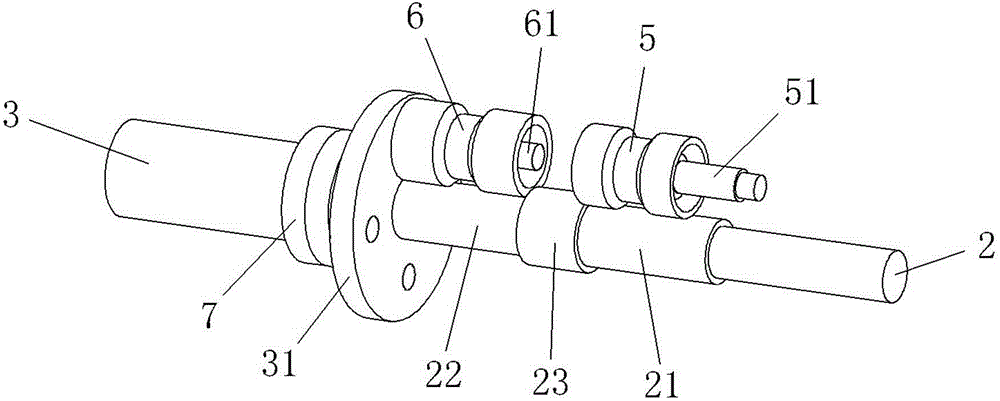

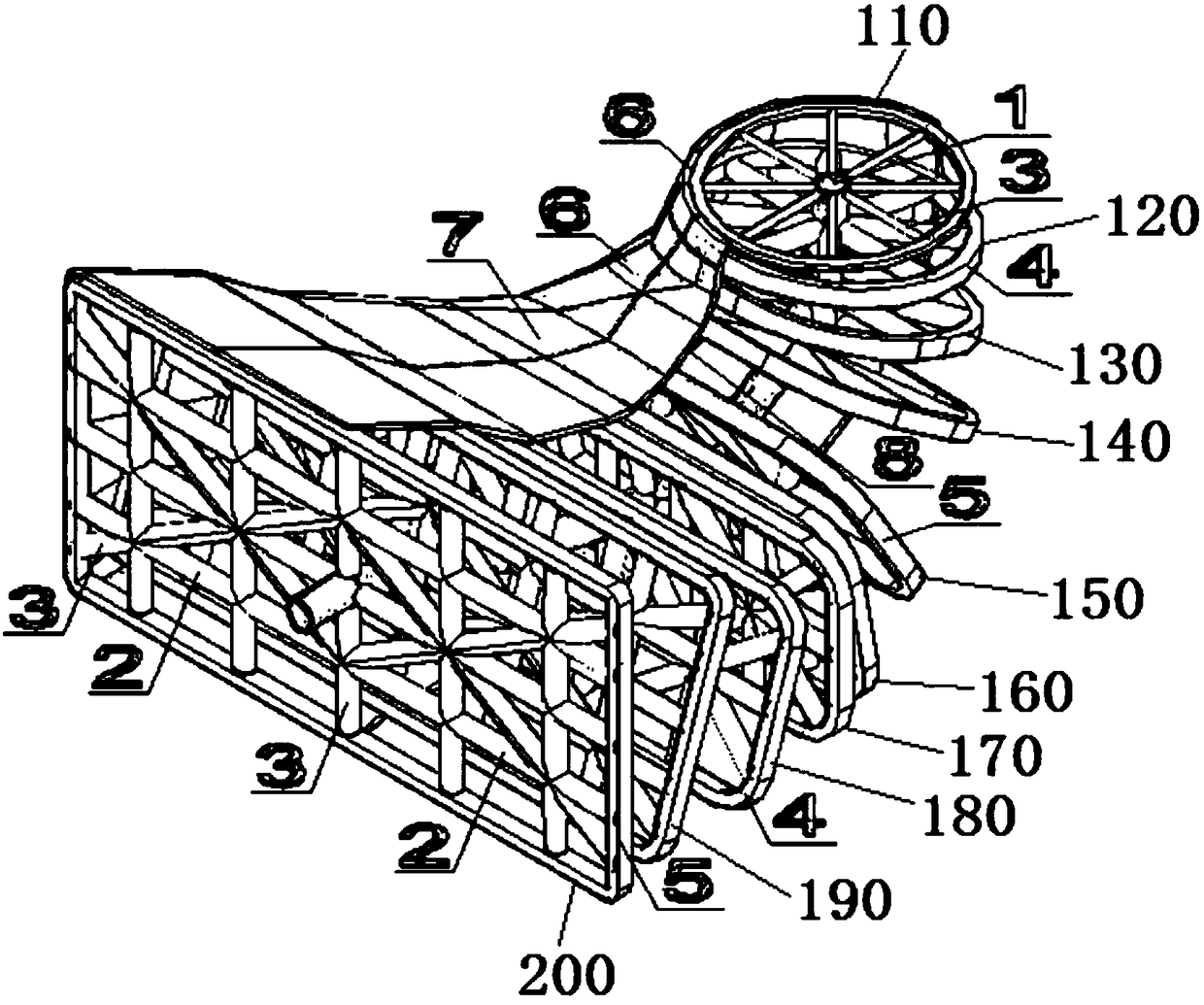

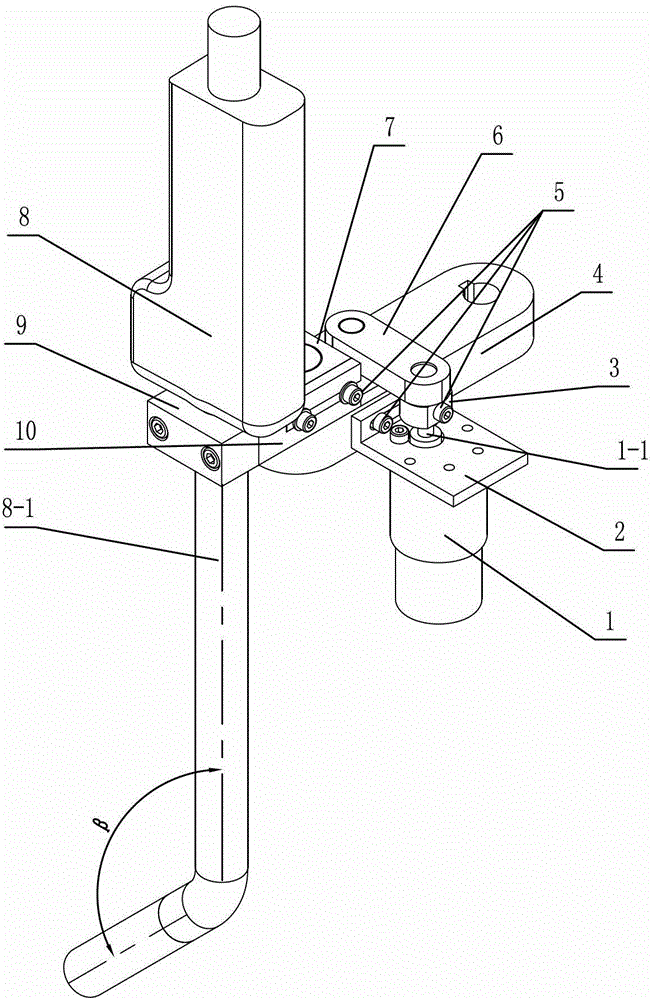

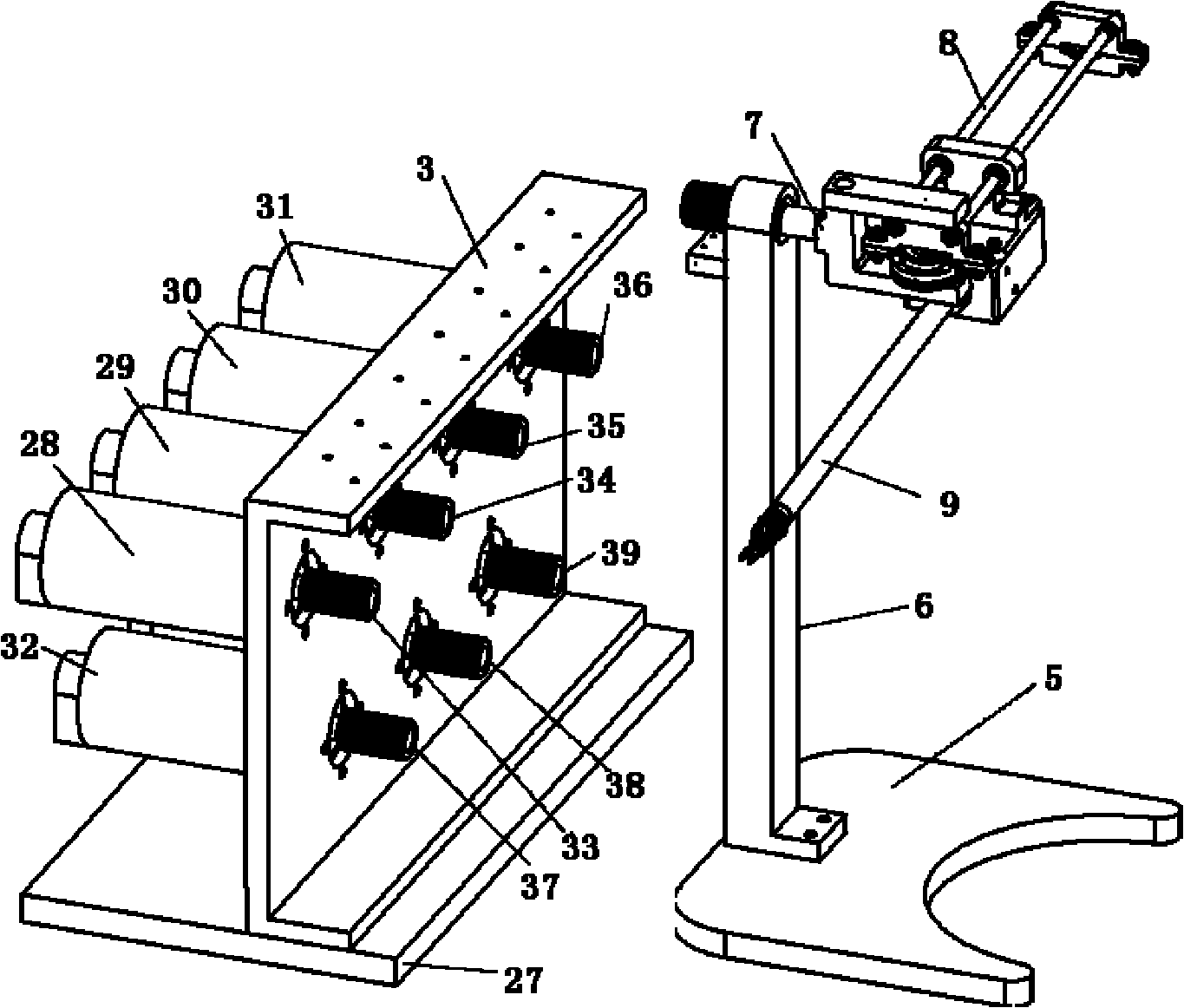

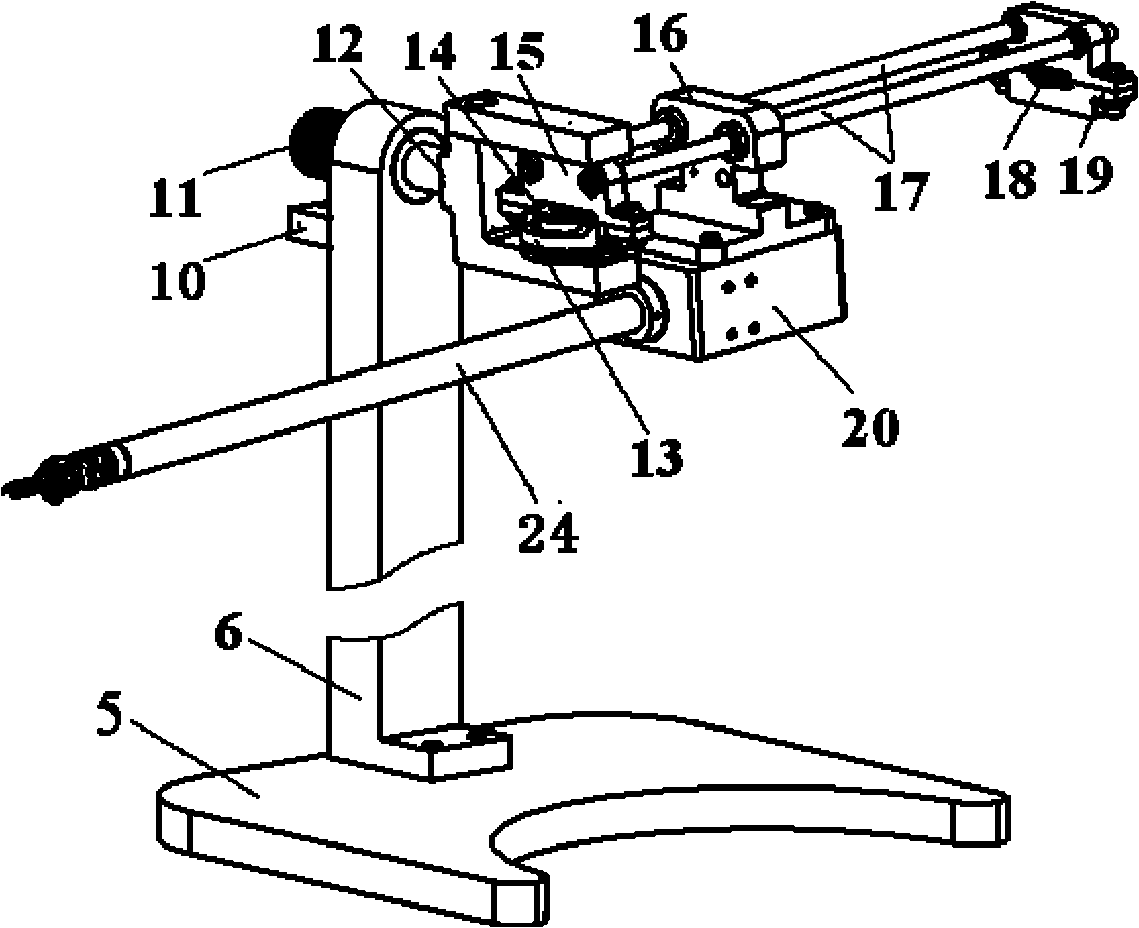

Seven- freedom degree mechanical slave-hand device for minimally invasive surgery

InactiveCN101797185BNo transmission gapSmall moment of inertiaProgramme-controlled manipulatorDiagnosticsLess invasive surgeryComputer module

The invention discloses a seven-degree of freedom (DOF) mechanical slave-hand device for a minimally invasive surgery, which comprises a mechanical slave-hand mechanism, a processing controller, a drive module and a sensor, wherein the processing controller is connected with the drive module which is connected with the mechanical slave-hand mechanism; and the sensor is connected with the drive module and the processing controller respectively so as to transmitting angular displacement and rotating speed information. The transmission form of the mechanical slave-hand mechanism is linear transmission; and in the linear transmission, the mechanical motion and moment between master and slave pieces are transmitted by means of a transmission line which is tightly wound on a line wheel. The seven-degree of freedom (DOF) mechanical slave-hand device for the minimally invasive surgery has the advantages of steady and continuous linear transmission, no transmission gap, small motion inertia, smooth drive and low cost, can realize complex operation of common minimally invasive surgeries, and has high flexibility.

Owner:SHANGHAI JIAO TONG UNIV

Water treatment air flotation slag scraper

ActiveCN106315729BImprove transmission efficiencyHigh transmission powerWater/sewage treatment by flotationBristleSlag

The invention discloses a water treatment gas floating slag scraper which comprises a slag scraper body, scraping bristles and wheels, wherein wheel shafts are arranged in the wheels; supporting frames are arranged above the wheels on the slag scraper body; a travel switch I is arranged on the supporting frames; a motor is arranged on the rear side of the slag scraper body; a chain wheel I is arranged on an output shaft of the motor; chain wheels II are arranged on the wheel shafts; the chain wheel I is connected with the chain wheels II through chains; a movable frame is arranged below the slag scraper body; the rear end of the movable frame is connected with the lower end surface of the slag scraper body; a long bolt is arranged between the front end of the slag scraper body and the movable frame; a connection frame is arranged at the front end of the movable frame; a connection plate III is arranged at the front end of the connection frame; the scraping bristles are located on the front end surface of the connection plate III; a cylinder is arranged on the front side of the slag scraper body; a connection plate V is arranged on the scraping bristles; a controller is arranged on the upper end surface of the slag scraper body; a hydraulic pump is arranged on the rear side of the controller. The water treatment gas floating slag scraper provided by the invention is simple in structure, good in slag scraping effect and convenient to operate.

Owner:SHANDONG PROVINCE WINSON NON WOVEN MATERIALS

Stamping device for automobile electronic components

ActiveCN109290423AReduce work intensityReduce processing timeMetal-working feeding devicesPositioning devicesElectronic componentPiston cylinder

The invention discloses a stamping device for automobile electronic components. The stamping device comprises an operating platform. Mounting plates are arranged at the lower end of a top plate. A first piston cylinder, a second piston cylinder and a third piston cylinder are arranged at the lower ends of the three mounting plates correspondingly. Piston rods are arranged inside the first piston cylinder, the second piston cylinder and the third piston cylinder correspondingly. A stamping rod is mounted at the lower end of each stamping plate. A first stamping head, a second stamping head anda third stamping head are arranged at the lower ends of the stamping rods. A mounting bracket is arranged at the other side of a hydraulic extending-and-contracting rod. A component clamp is mounted at the lower end of the mounting bracket and provided with a sliding rotating shaft seat. Support pillars are mounted at the bottom end of the operating platform. A containing box is arranged below theoperating platform. By means of the stamping device, the automobile electronic components of different specifications can be stamped at the same time and gripped through the component clamp; and theelectronic components are prevented from being damaged.

Owner:刘兆

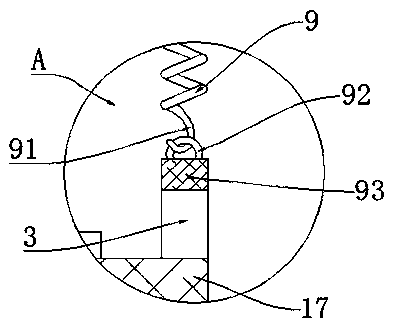

Lifting type submersible pump with strong stability

InactiveCN109058152AImprove stabilityWaterproofPump componentsPump installationsMedial axisArchitectural engineering

The invention discloses a lifting type submersible pump with strong stability. The lifting type submersible pump comprises a lifting platform, a first telescopic column, a second telescopic column, and a hydraulic rod, wherein both ends of the lifting platform are provided with second telescopic support rods; both sides of the lifting platform are provided with first telescopic support rods; the other ends of the first telescopic column and the second telescopic column are provided with fulcrum rods; the exact middle between the first telescopic column and the second telescopic column is provided with a medial axis rod; a submersible pump is arranged below the first telescopic column and the second telescopic column; lifting rings are installed on an upper end of the submersible pump; thelifting ring and the first telescopic column are connected by chains; one end of the hydraulic rod is provided with a hydraulic rod fixing end; the other end of the hydraulic rod is provided with a hydraulic rod telescopic end; the hydraulic rod fixing end is connected to the fulcrum rod through a fixing end shaft; and the hydraulic rod telescopic end is connected to the medial axis rod through atelescopic end shaft. According to the lifting type submersible pump with strong stability, lifting and droping of the submersible pump is realizesd through the hydraulic rod, so that droping is morestable, laborious problem of manual lifting and problem of easy degeneration during the droping are solved.

Owner:TIANJIN MINGAO PUMP CO LTD

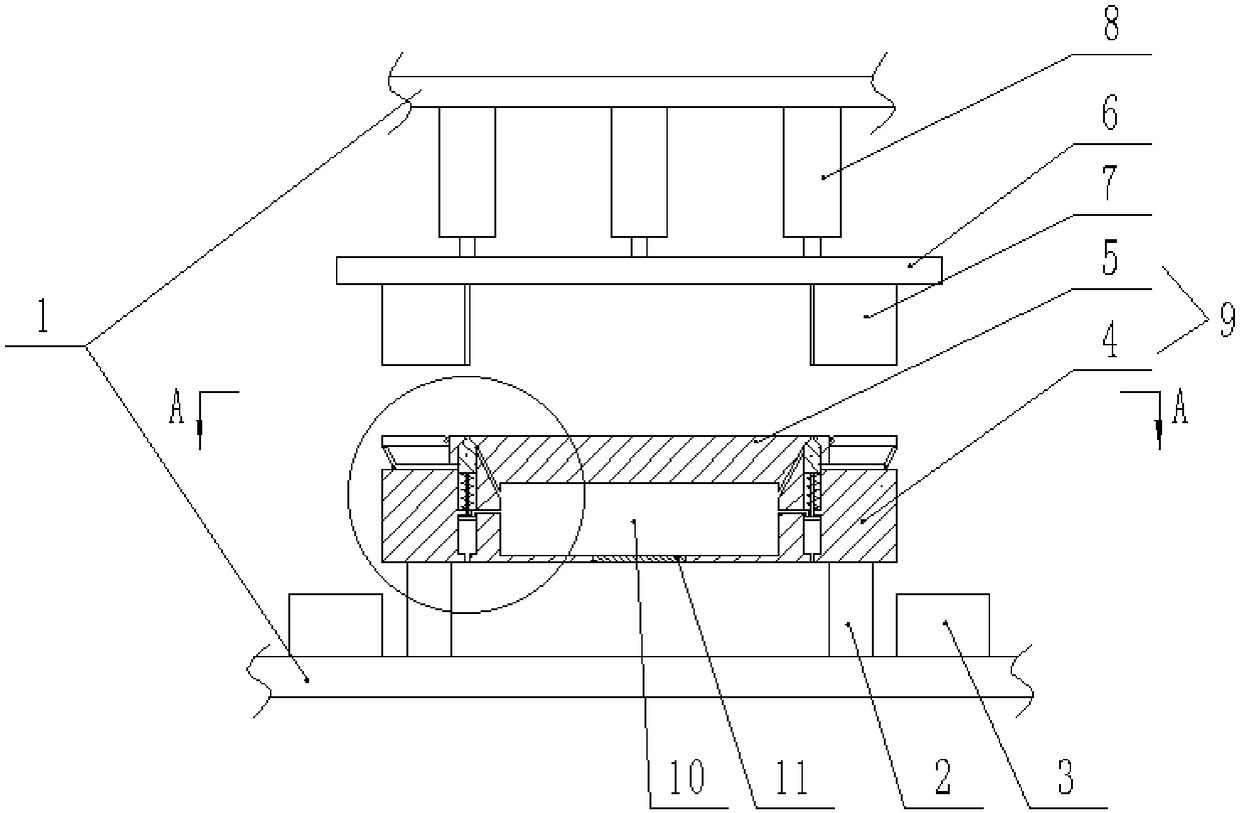

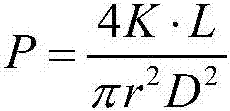

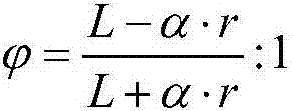

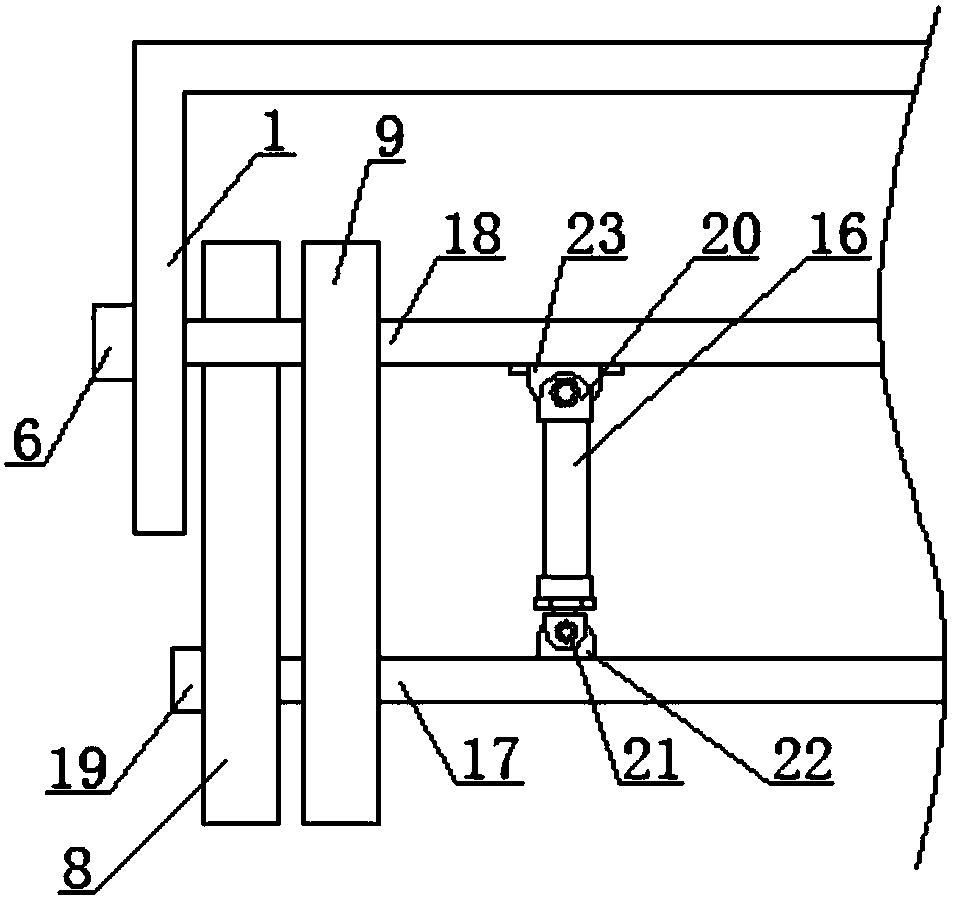

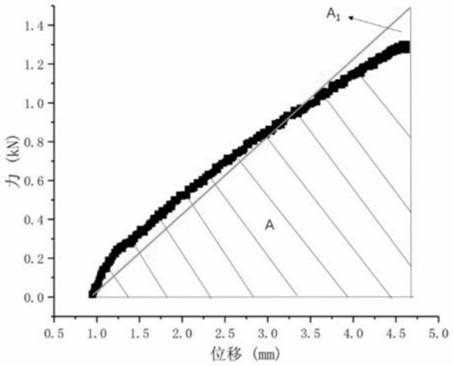

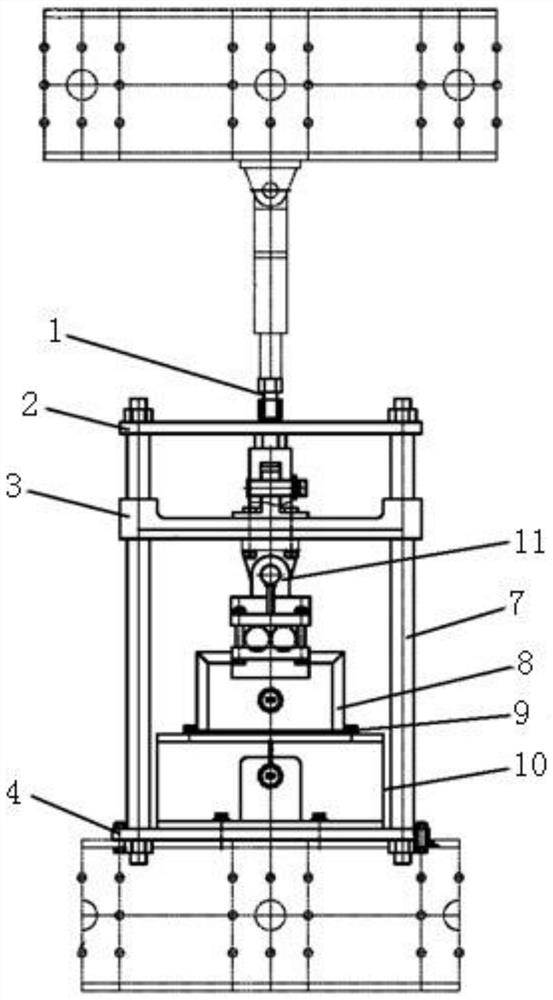

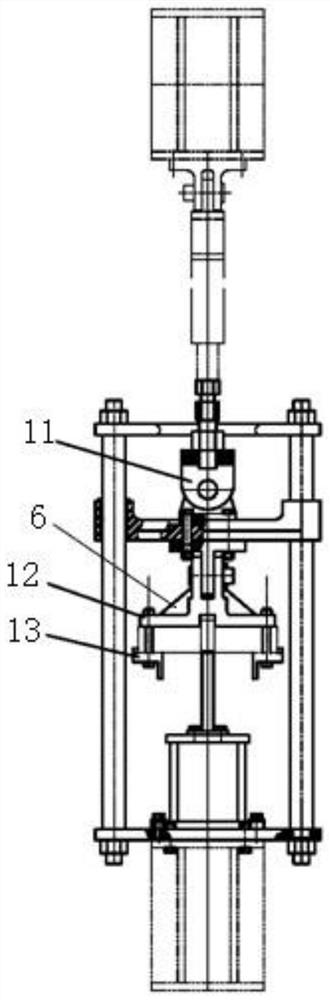

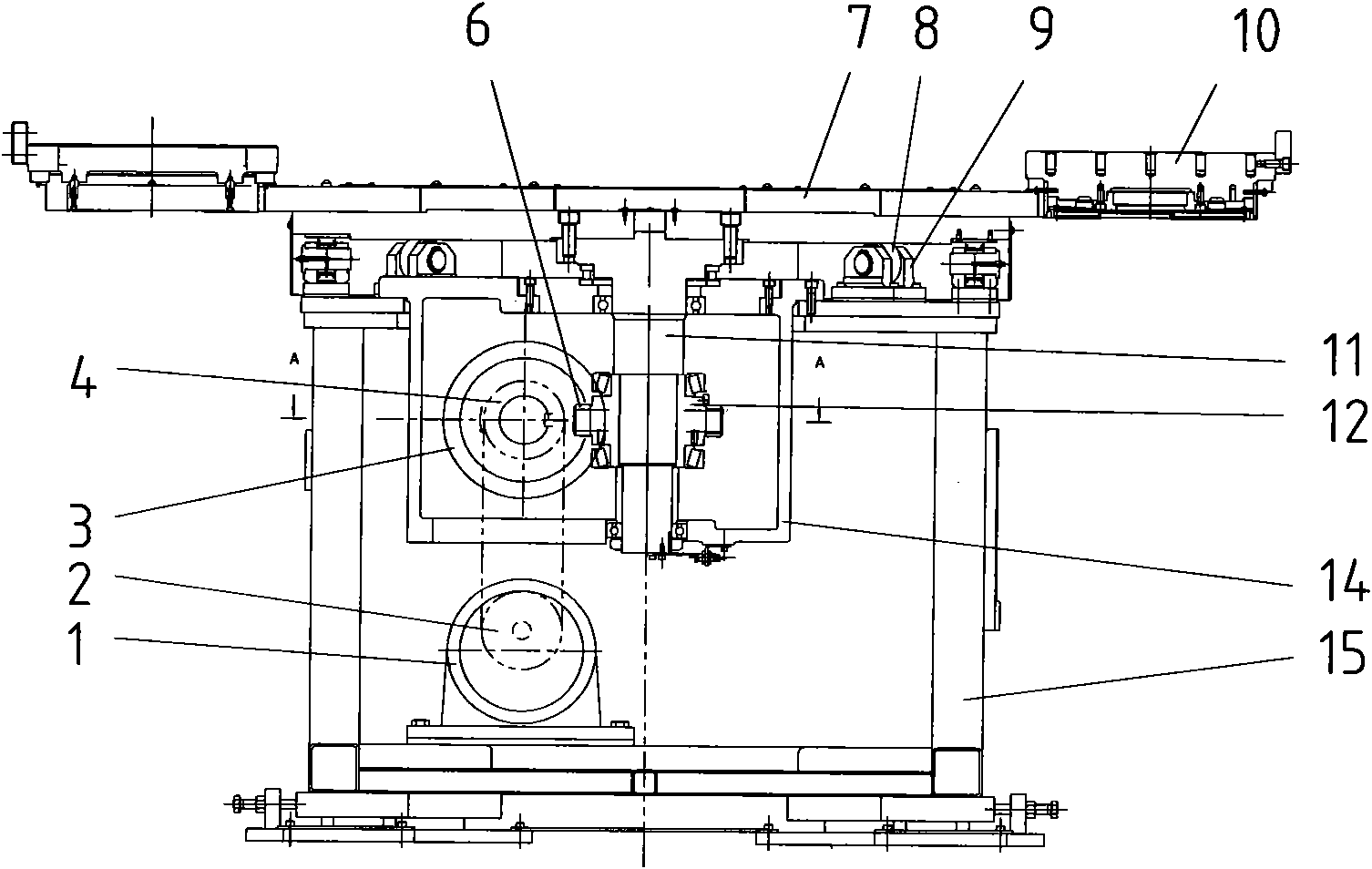

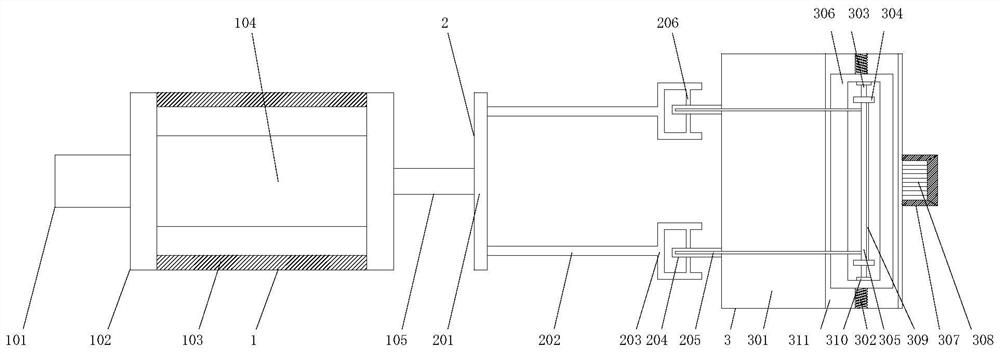

A static stiffness test device and test method for a ship system pipeline support

ActiveCN110108424BGuaranteed contactEasy to replaceMachine part testingElasticity measurementMarine engineeringPipe support

The invention relates to a static stiffness testing device and testing method for a ship system pipeline support, comprising a main body frame, a loading device and a pipeline support and clamping device, the main body frame includes an upper fixing frame and a lower fixing seat arranged symmetrically up and down, and the The four guide columns at the four corners are connected; the loading device includes a screw, a sliding platform and a pressure head. The bottom of the sliding platform is connected, and the four corners of the sliding platform are socketed and connected with four guide columns, and slide up and down along the guide columns; the pipeline support and clamping device includes a tube support plate, a tube support gasket, a pipeline support and a The plate is arranged at the bottom of the pipeline, and the pipe support gasket is arranged on both sides of the pressure head to be symmetrical with the pipe support plate up and down, and connected by bolts. The invention is easy to operate, high in reliability and good in versatility.

Owner:CHINA SHIP DEV & DESIGN CENT

A step-down auxiliary mechanism for a crawler-type operating device

ActiveCN105151142BSimple structureWork reliablyEndless track vehiclesEngineeringIndustrial engineering

Owner:FUJIAN QIAOLONG EMERGENCY EQUIP CO LTD

Eight-station sorting mechanism indexed by cambered surface cam

InactiveCN101982294BSimple structureLess workpiecePrecision positioning equipmentMetal working apparatusEngineeringCam

The invention discloses an eight-station sorting mechanism indexed by a cambered surface cam, comprising a rack and a motor installed on the rack, wherein an eight-station index plate is arranged above the rack, the center below the eight-station index plate is fixedly connected with a vertical shaft, the vertical shaft is installed on an installation rack fixedly connected with the rack, a supporting wheel is arranged above the rack to support the eight-station index plate, and a link transmission mechanism and a cambered surface cam transmission mechanism are arranged between the vertical shaft and the motor. The mechanism has simple integral structure, few workpieces and small land occupation, does not generate a driving gap during the conversion of positive rotation and reverse rotation, and has accurate indexing and high processing precision of workpieces.

Owner:DALIAN HUAGEN MACHINERY

A hydraulic -driven eight -foot thrust bearing base

ActiveCN106640985BUniform load distributionReduce vibration and noisePropulsive elementsPropulsive transmissionThrust bearingActuator

The invention discloses a hydraulic-driven eight-foot thrust bearing base, comprising a shaft, a thrust bearing, a support assembly and a base, wherein the shaft passes through the thrust bearing; the support assembly comprises two actuator groups which are respectively and symmetrically distributed at two sides of the thrust bearing; each actuator group comprises four actuators, two upper part connecting blocks positioned at one side of the thrust bearing, and three lower part connecting blocks arranged on the base; an 'M'-shaped structure is formed by the actuators, the upper part connecting blocks and the lower part connecting blocks of each actuator group; the upper part connecting blocks, the lower part connecting blocks and the actuators are connected in a way of spherical hinge connection. The thrust bearing base provided by the invention is simple, efficient and flexible; after the design is adopted, the bearing load can be evenly distributed, the working performance of a shaft system is improved, the normal operation of the shaft system is guaranteed, and active and passive control can be also effectively carried out on the vibration of the shaft system.

Owner:SHANGHAI JIAO TONG UNIV

Full-automatic hydraulic automatic tensioning device for conveying belt

The invention discloses a full-automatic hydraulic automatic tensioning device for a conveying belt. A hydraulic oil cylinder device, a conveying device and a tensioning device body are included, theconveying device is movably installed on the right side of the front face of the hydraulic oil cylinder device, and the tensioning device body is movably installed on the right side of the front faceof the conveying device. The hydraulic oil cylinder device is composed of a pressing rod, a gland, a supporting rod, a cylinder barrel, a hydraulic driving rod, a piston body, an elastic spring, a fixing piece and a supporting bridge, the pressing rod is movably installed in the center of the left side of the front face of the hydraulic oil cylinder device, the right side of the front face of thepressing rod is movably connected with the gland, and the cylinder barrel is movably arranged at the center of the right side of the front face of the gland. According to the full-automatic hydraulicautomatic tensioning device for the conveying belt, a driving motor is started, a sliding groove formed in the right side of the surface of a fixed base is tensioned, extension springs movably installed at the two ends of the front face of the sliding groove horizontally move, threads arranged on the front faces of sliding rods are matched with inner shafts arranged on the inner sides of the frontfaces of rotating wheels, the inner shafts are rotationally connected with the sliding rods, the automatic tensioning technology of the device is effectively carried out, and the conveying efficiencyis improved.

Owner:浙江拓邦液压科技有限公司

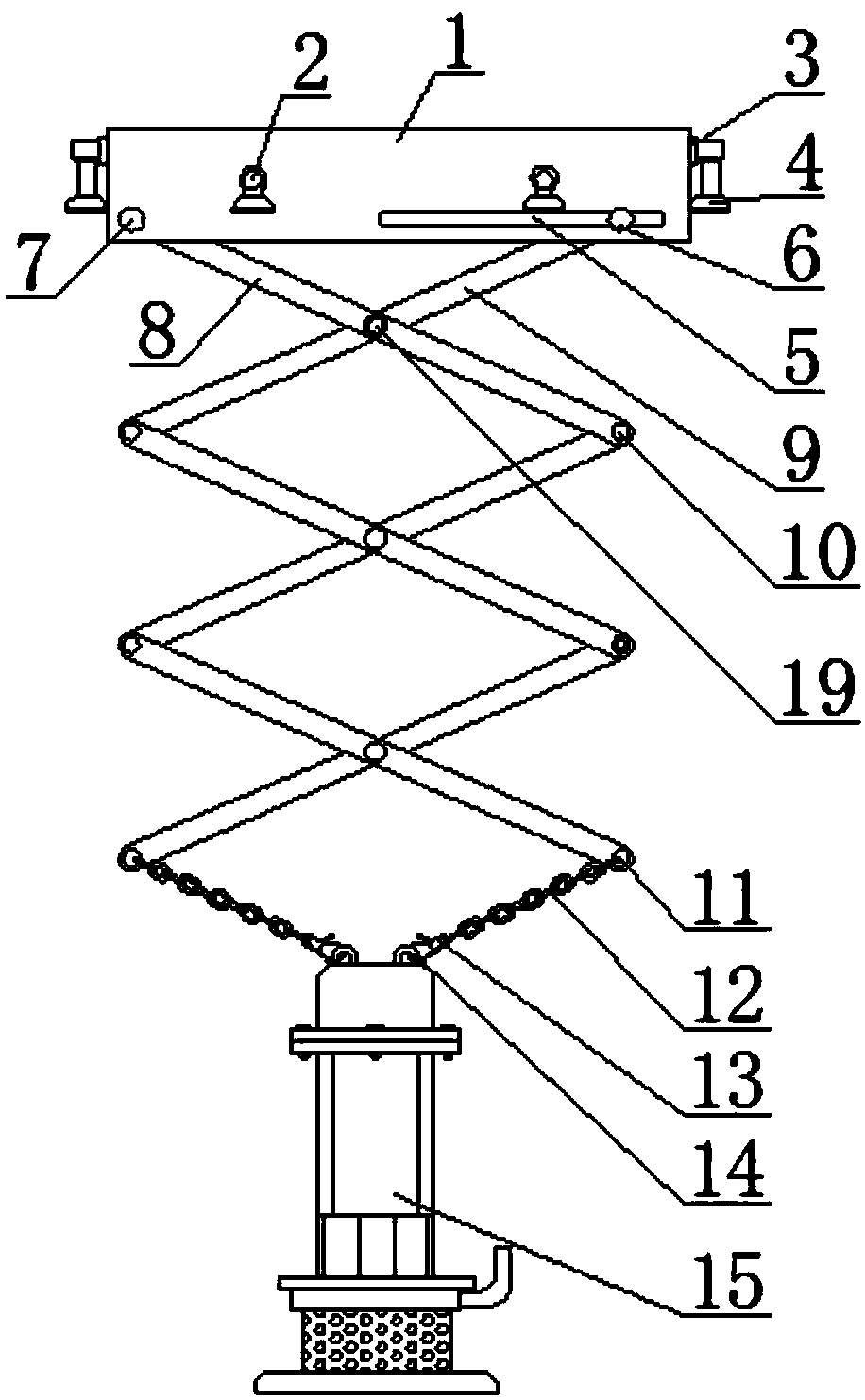

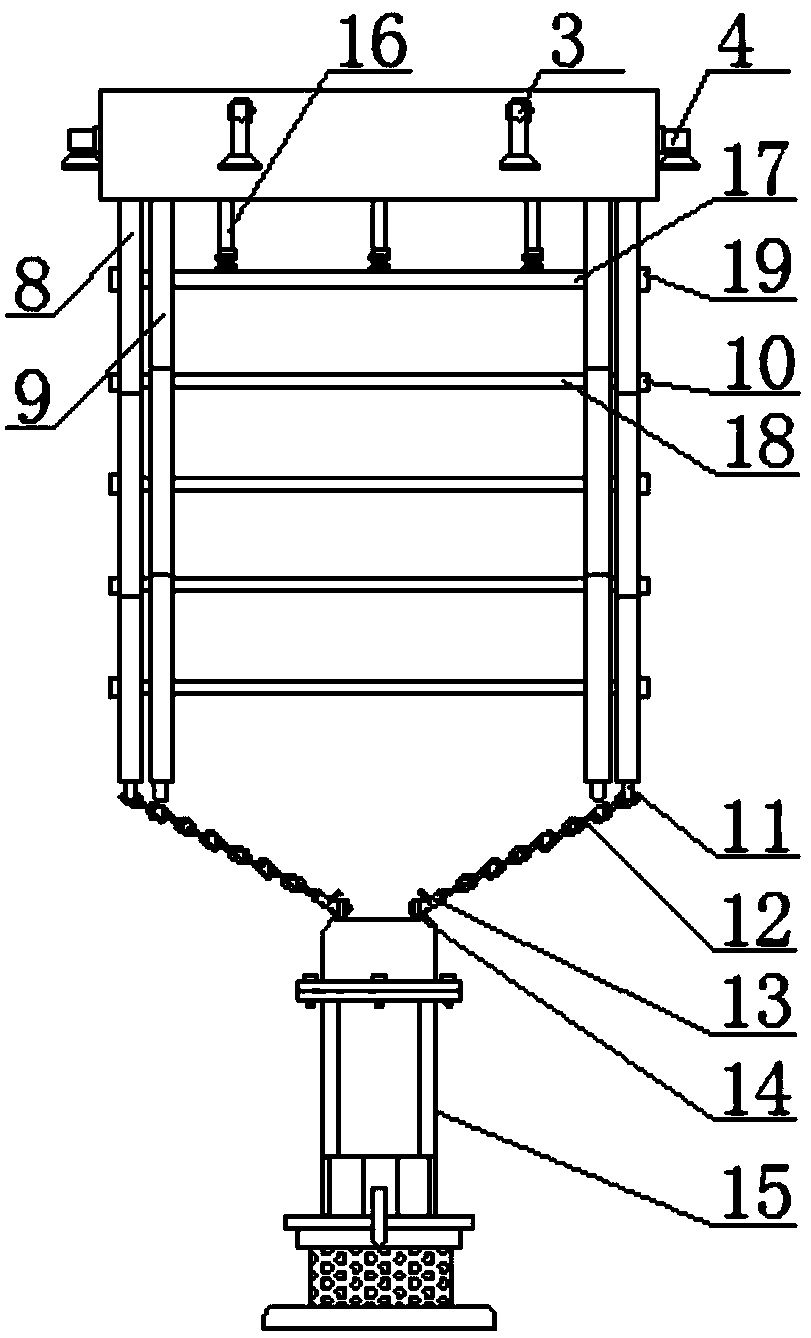

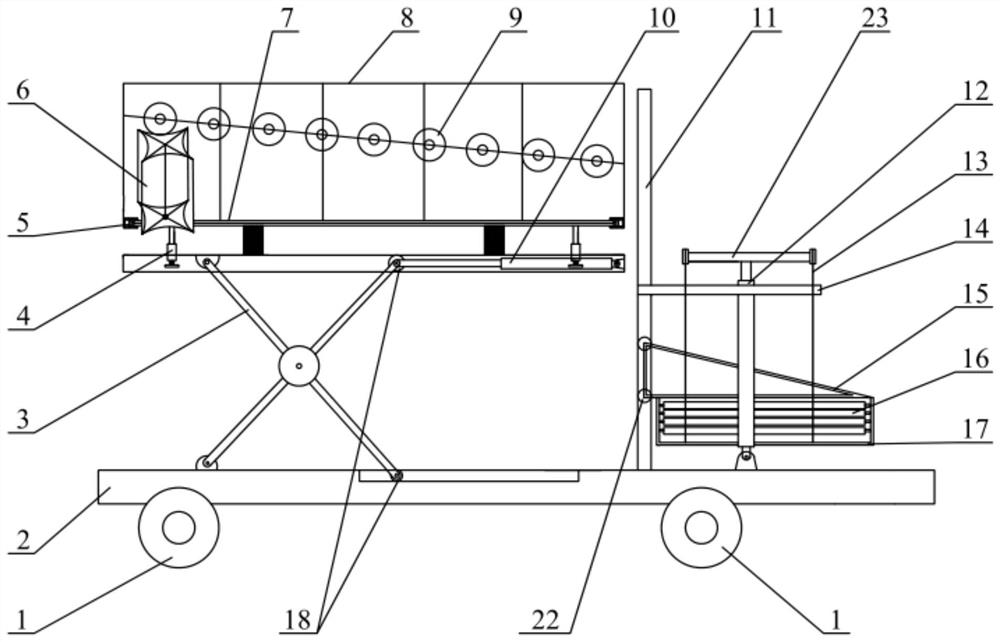

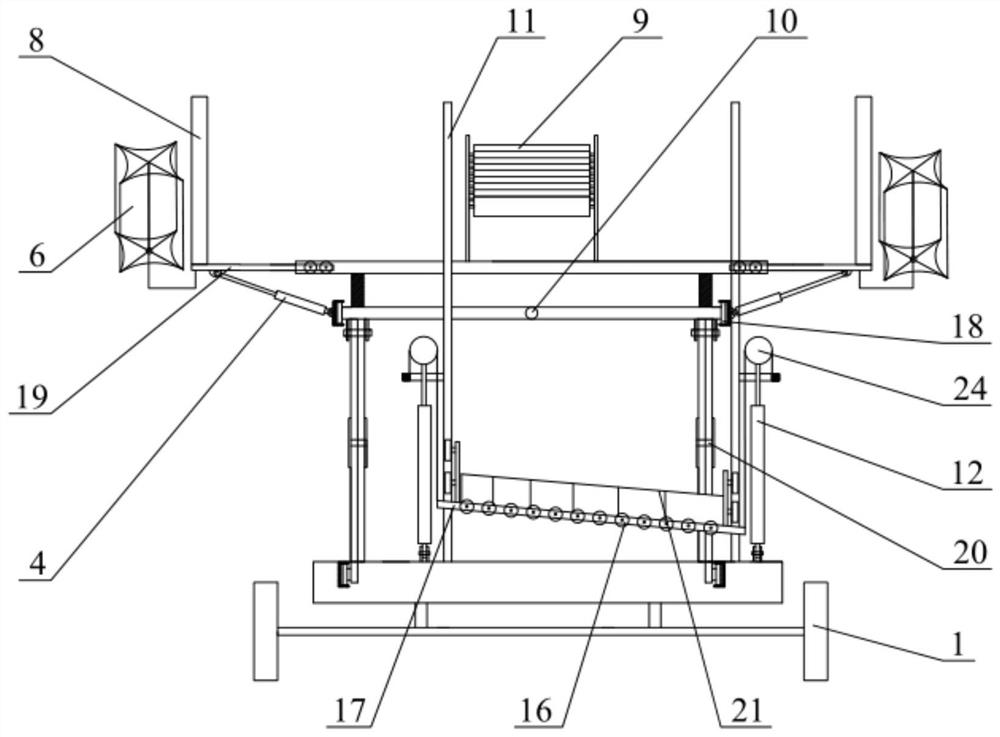

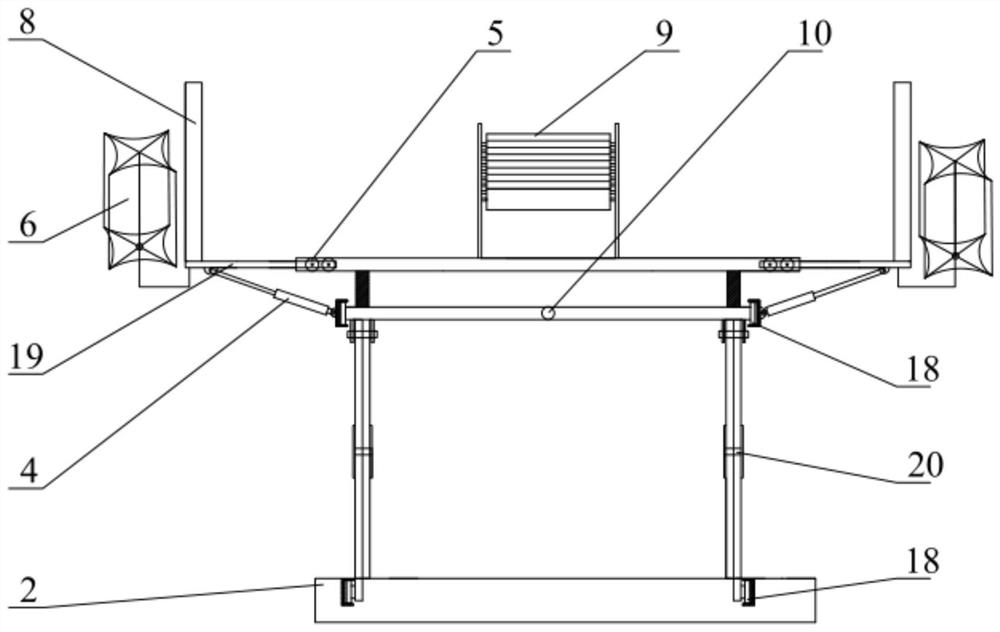

A multifunctional apple picking operation platform and using method thereof

ActiveCN107996138BSimple structureWork reliablyConveyorsSupporting framesFruit treeHydraulic cylinder

The invention discloses a multifunctional apple picking operation platform and its use method. The apple picking operation platform includes a picking platform and a fruit box collection platform, the picking platform and the fruit box collection platform are fixed on the platform base, and the platform base is provided with four a walking wheel; the picking platform is equipped with a fork-type lifting bracket, which is cross-connected by a pin shaft, and the top of the bracket is connected with the main body of the picking platform; The dial; the fruit box collection platform includes a collection platform main body, a fixed bracket, and a chain; the invention controls the operating range of the picking platform through a hydraulic cylinder, and transports the fruit boxes through a transmission roller. The operation platform of the present invention is used for picking operations and fruit box transportation, and can walk freely. The dial wheel protects the fruit trees and fruits during the travel process. At the same time, the operation platform is stable and reliable. The platform size can be adjusted according to different plant row spacing and plant height. scope of work.

Owner:QINGDAO AGRI UNIV

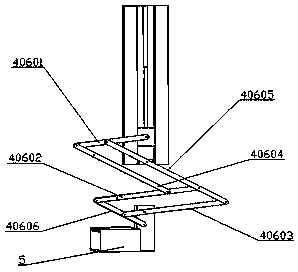

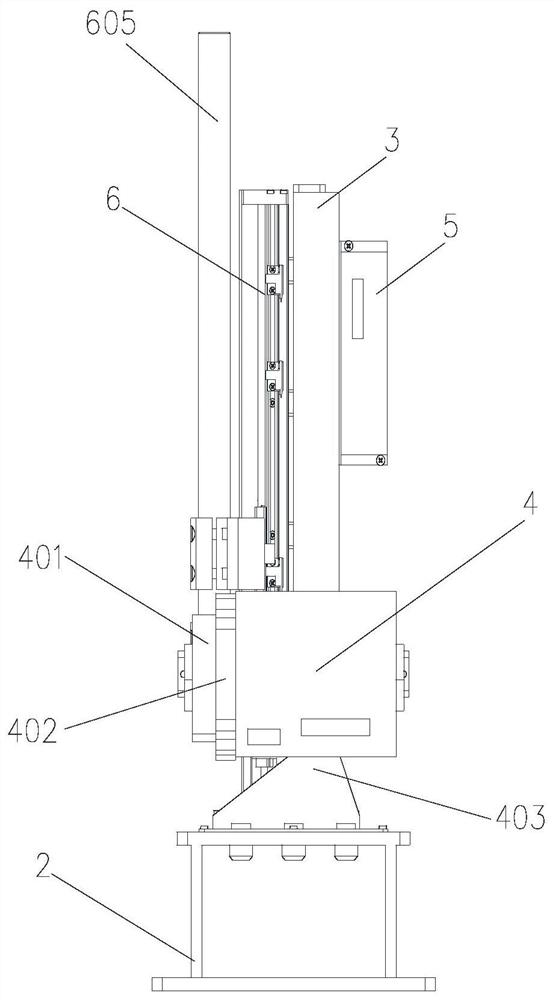

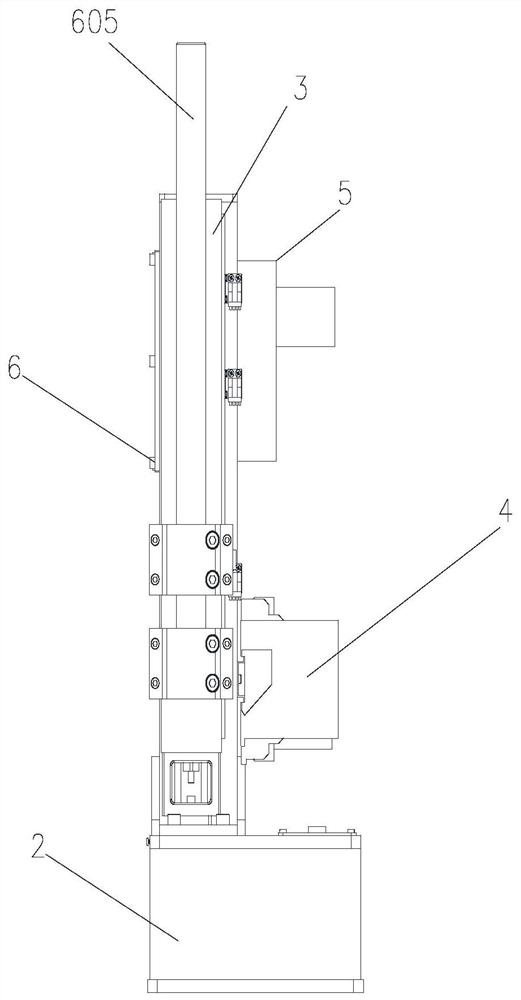

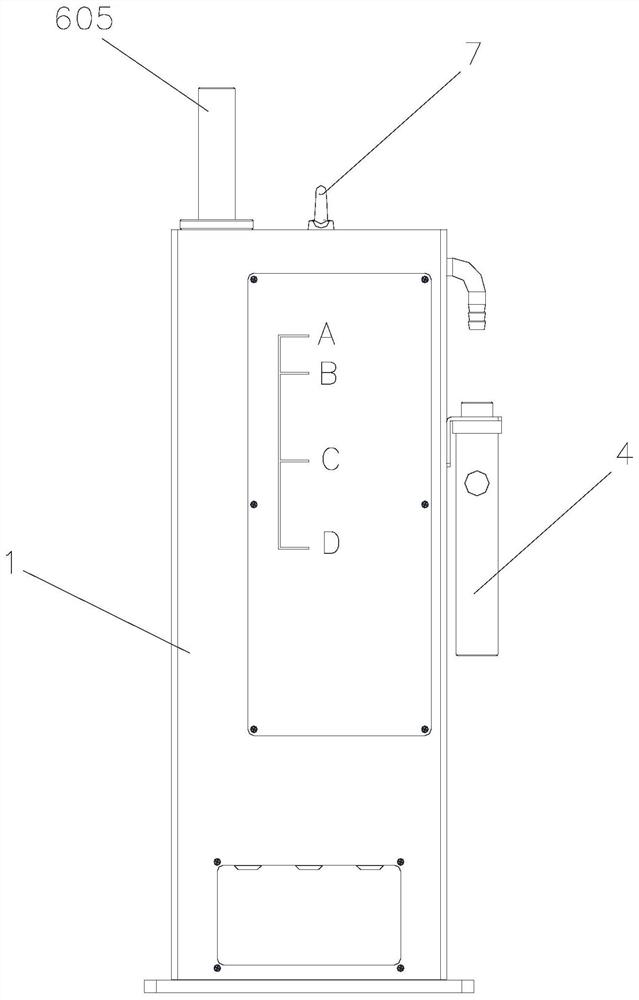

A glass level gauge

ActiveCN110864763BCompact structureEasy maintenanceLevel indicators by physical variable measurementInterference fitBall screw

The invention provides a glass liquid level meter. The glass liquid level meter comprises a base used for being fixed to a user field mounting base, a stand column used for being matched with the baseto form a supporting frame, a controller used for recording and transmitting signals, a single-axis robot used for controlling a probe to move up and down, and a servo driver used for controlling thesingle-axis robot. The stand column is vertically arranged above the base, the controller is arranged on the stand column and located at the end close to the base, the single-axis robot is arranged on the stand column and located on the side adjacent to the controller, and the servo driver is arranged on the stand column and located on the side opposite to the single-axis robot. The integrated design is adopted, the structure is compact, maintenance is convenient, the production cost is effectively reduced, and the reliability of the device is improved; and moreover, linear guide rail guidingand ball screw displacement transmission are adopted, interference fit is adopted, no transmission gap exists, and therefore, high-precision and low-inertia transmission is achieved, and the measurement precision of the whole device is guaranteed.

Owner:XIAN WEIMIKE AUTOMATIC CONTROL INSTR TECH

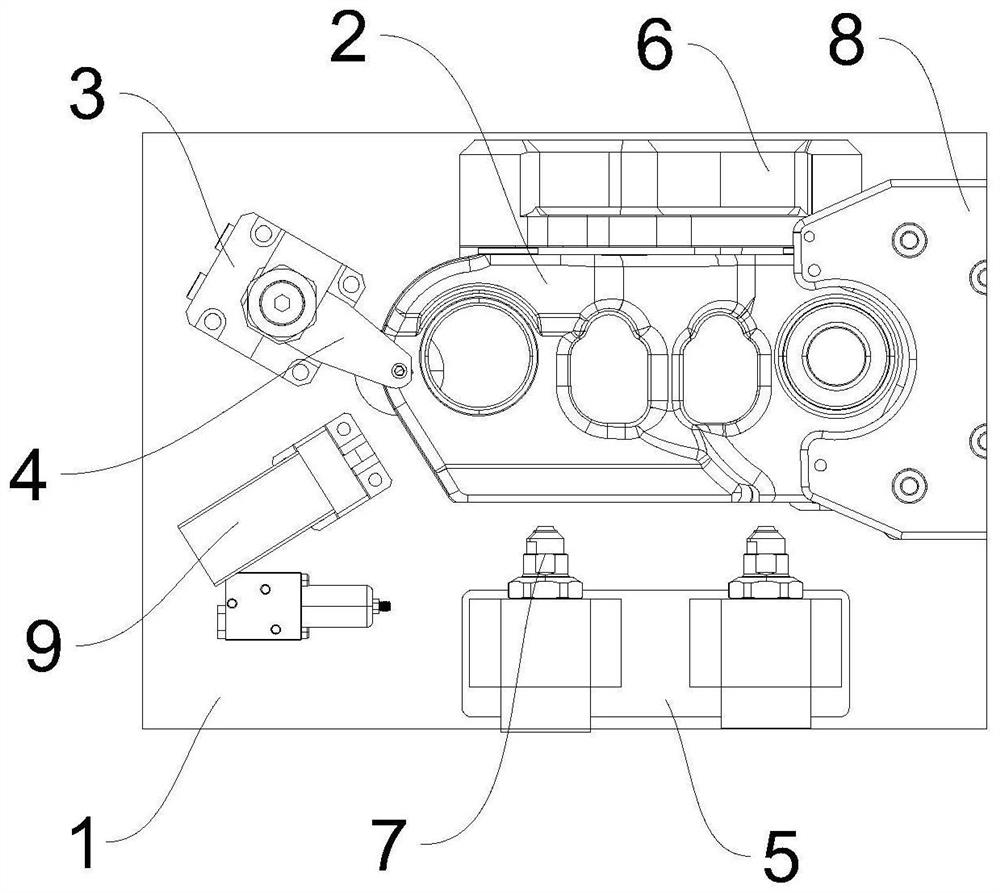

Clamping tool for track link section finish machining

PendingCN114131384ASimple structureSports reliablePositioning apparatusMetal-working holdersHydraulic ramEngineering

The invention provides a clamping tool for caterpillar track section finish machining, and relates to the technical field of caterpillar track section machining equipment. According to the scheme, the clamping tool for caterpillar link section finish machining comprises a mounting base plate, a first hydraulic oil cylinder arranged on one side of the mounting base plate and a second hydraulic oil cylinder arranged on the other side of the mounting base plate, a rotating cylinder matched with the first hydraulic oil cylinder is arranged on one side of the mounting base plate, and the output end of the rotating cylinder is connected with a rotating pressing plate; and a limiting piece matched with the second hydraulic oil cylinder is arranged on the other side of the mounting base plate. The caterpillar track section can be clamped and fixed during finish machining of the caterpillar track section, and the machining precision of the caterpillar track section during finish machining is improved.

Owner:钢客履带(江苏)有限公司

A driving device for reciprocating motion around an axis

InactiveCN107196454BAir chamber inflation is precisely adjustableReduce demandMechanical energy handlingReciprocating motionMotion parameter

The invention discloses a driving device for reciprocating motion around a shaft. The driving device comprises a driving motor for outputting a torque period and with adjustable curve, wherein the driving motor is used for outputting periodic torque driving load; one or more parameter adjustable energy storages for absorbing the energy in the load deceleration and outputting the energy in the load acceleration; a load base with adjustable reciprocating motion period, adjustable reciprocating motion zero position and adjustable reciprocating motion angle amplitude. The driving device disclosed by the invention is used for driving the load to perform the reciprocating motion around the shaft, a rotating shaft is directly driven by using a moment motor, a mechanical transmission device is cancelled, and the energy storage is provided; the driving device disclosed by the invention has the advantages of being adjustable in motion parameter, simple in transmission mechanism, convenient in analysis and computation method, low in energy consumption, high in reliability, low in noise and low in cost.

Owner:南京智真电子科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com