A reusable hydraulic combined special-shaped steel formwork and disassembly method

A special-shaped steel and hydraulic technology, which is applied to formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve the problem of affecting the operating life of the runner and the efficiency of the unit, inconvenient for reuse, and inconvenient for secondary positioning. Accuracy and other issues, to achieve the effect of good hydraulic characteristics of the pumping station, good consistency of pouring quality, and small misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

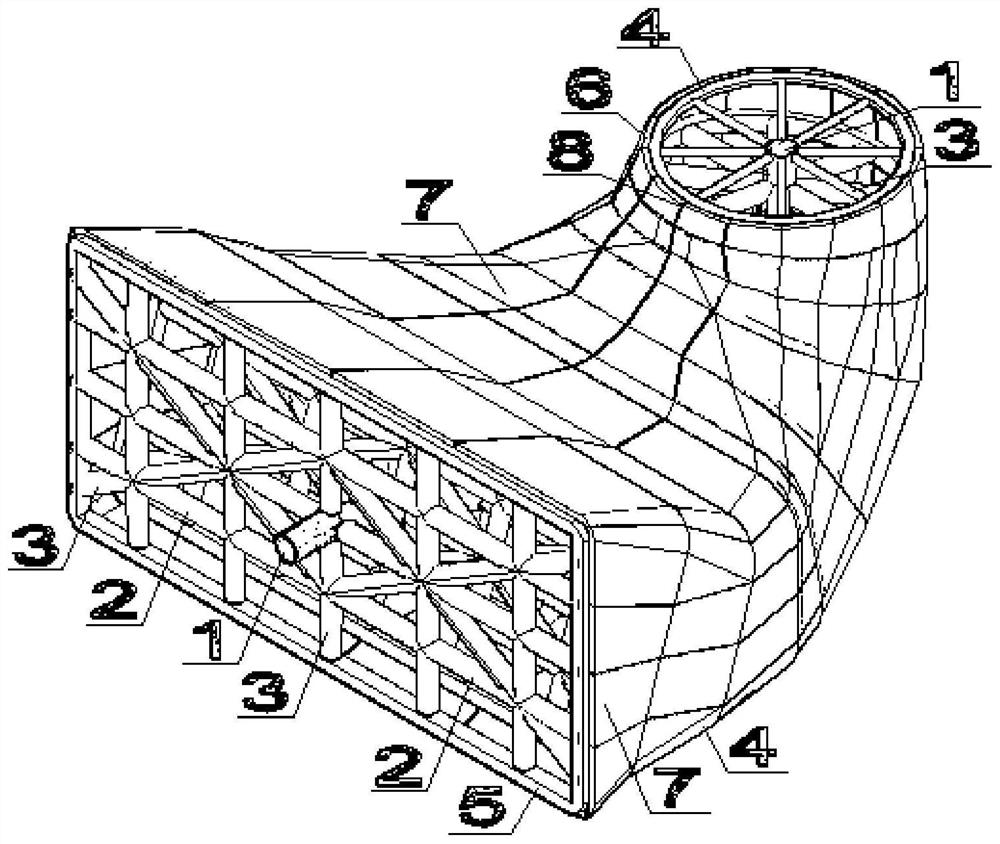

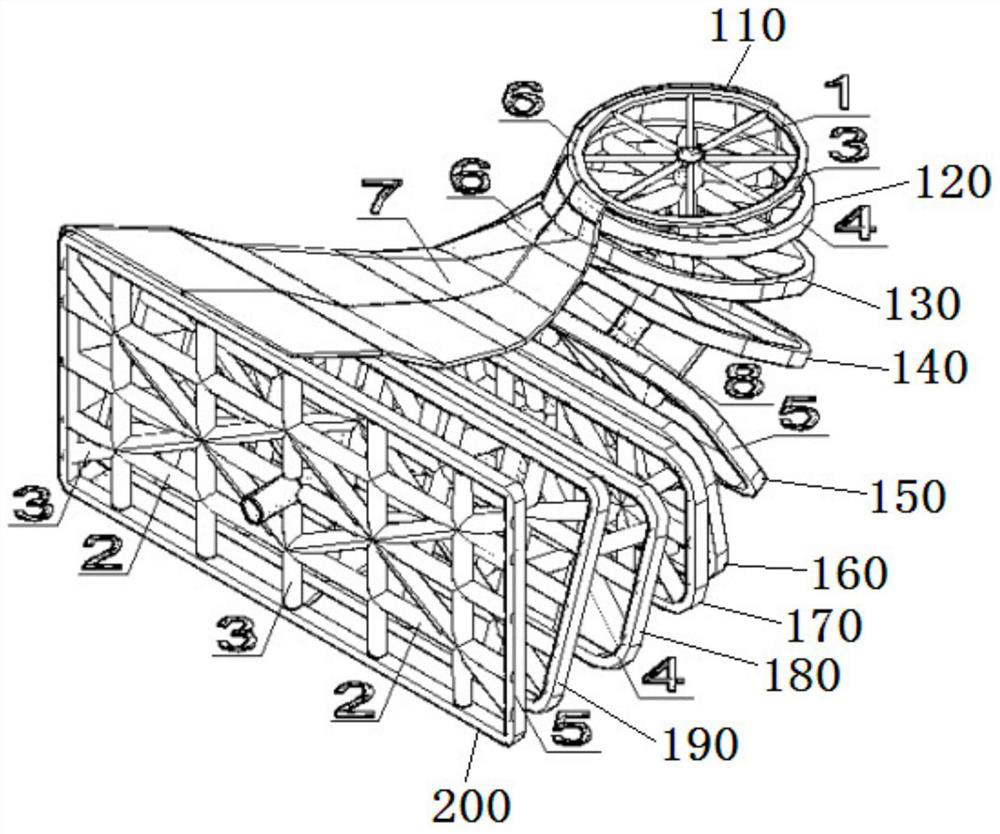

[0043] A reusable hydraulically combined special-shaped steel formwork is used for pouring the elbow section of the flow channel of the pump station, so it has the same shape and structure as the elbow section of the flow channel of the pump station.

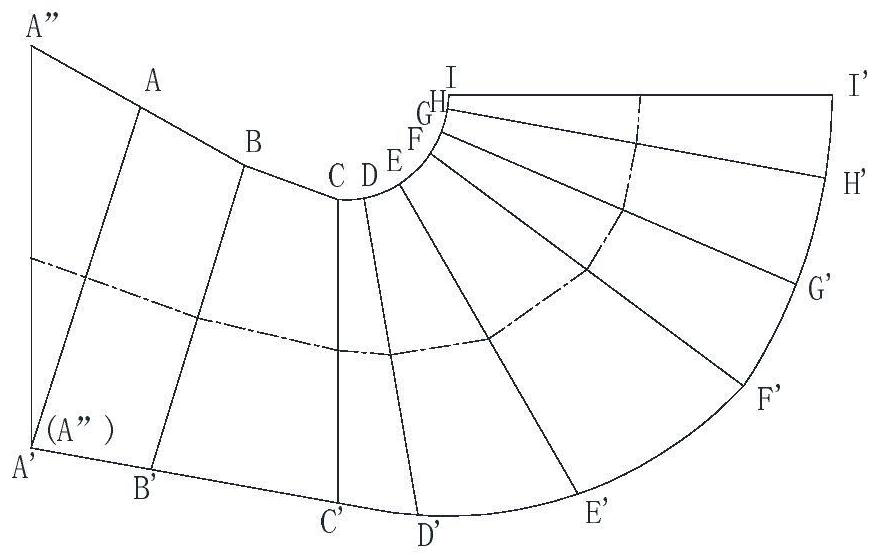

[0044] The elbow section of the flow path of the pump station has ten special-shaped sections, including four circular sections of different sizes and six rectangular sections of different sizes, and the four corners of the rectangular sections are arc-shaped.

[0045] Therefore, a kind of hydraulically combined special-shaped steel formwork that can be reused of the present invention, such as image 3 and Figure 4 As shown, there are also ten special-shaped sections. The ten special-shaped sections are A-A'~I-I' and A"-A", a total of ten sections.

[0046] Such as figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com