Driving device for reciprocating motion around shaft

A reciprocating motion and driving device technology, applied in the direction of electromechanical devices, electric components, control mechanical energy, etc., can solve problems such as difficult control, low cost, and complex transmission rules, so as to reduce torque requirements and operating energy consumption, and facilitate control parameters Excellent design, good dynamic response performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further explained below in conjunction with the drawings.

[0026] The driving device for reciprocating movement around an axis of the present invention includes: a driving motor with an adjustable repetition period of output torque and an adjustable curve of output torque with respect to the angle of rotation, which is used to output periodic torque to drive the load; the parameters are adjustable The energy storage device is used to absorb energy when the load decelerates and output energy when the load accelerates; a load base. The reciprocating movement period is adjustable, the reciprocating movement zero point position is adjustable, and the reciprocating movement angle amplitude is adjustable.

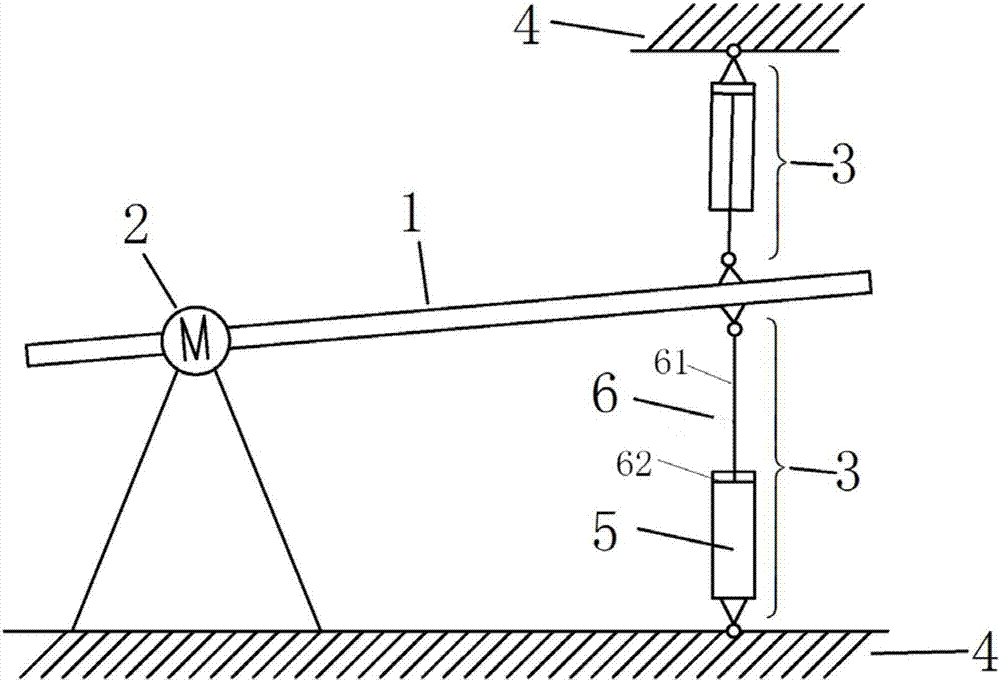

[0027] Specific, such as figure 1 , Including load base 1, drive motor 2, energy storage 3, fixed base 4; the rotating shaft of load base 1 is mounted on the output shaft of drive motor 2; the housing of drive motor 2 is mounted on fixed base 4; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com