Arc swinging device applied to automatic metal welding

An automatic welding and metal technology, applied in the field of swinging arc device, can solve the problems of difficult control, complex structure, difficult maintenance, etc., and achieve the effect of convenient welding seam width, simple adjustment and control, convenient disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

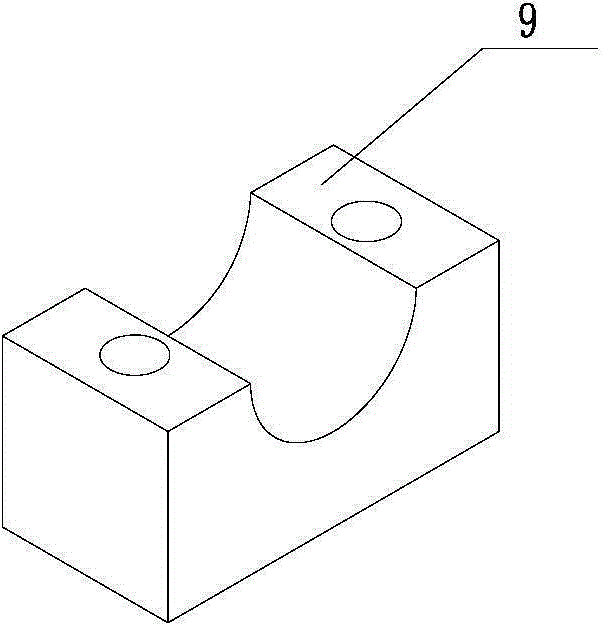

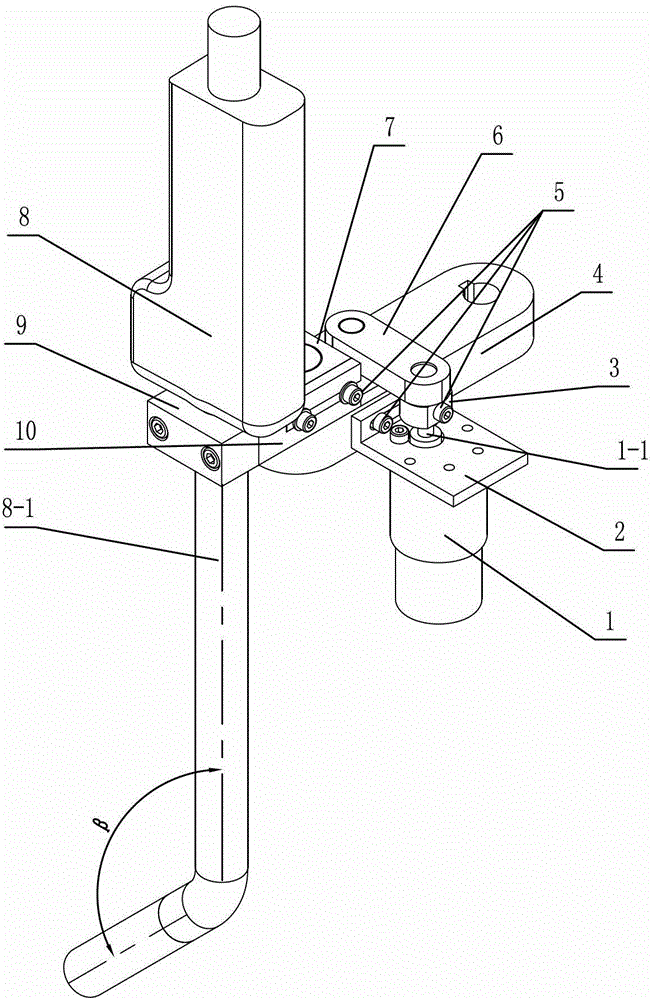

[0020] See figure 1 As shown, the swing arc device for automatic metal welding of the present invention includes a welding torch 8, a swing arc crank linkage mechanism, and a welding torch clamping and welding seam width adjusting mechanism.

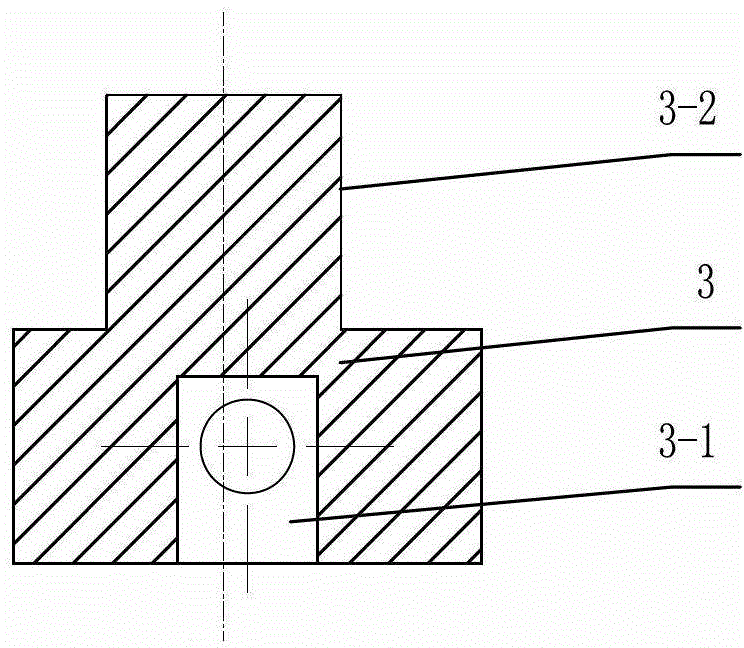

[0021] See Figure 1-4 As shown, the swing arc crank linkage mechanism of the present invention includes a base plate 4, a DC motor 1, an eccentric wheel 3, a connecting rod 6, and a swing guide plate 7. The DC motor 1 is connected to the base plate 4, and the DC motor 1 can adopt a deceleration mechanism. DC motors, see figure 1 As shown, the DC motor 1 of the present invention is installed on the angular motor base 2, and the other side of the motor base 2 is installed on the base plate 4 by a fastener 5, and the output shaft 1-1 of the DC motor 1 and the eccentric wheel 3 Connected, the two sides of the connecting rod 6 are respectively hinged on the eccentric wheel 3 and the swing guide plate 7, and the direct current motor 1 drive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com