Water treatment gas floating slag scraper

A slag scraper and water treatment technology, applied in the direction of flotation water/sewage treatment, etc., can solve the problems of high operating cost, failure to meet the requirements of process use, cumbersome manufacturing process, etc., and achieve high transmission efficiency, strong adaptability, The effect of high transmission power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

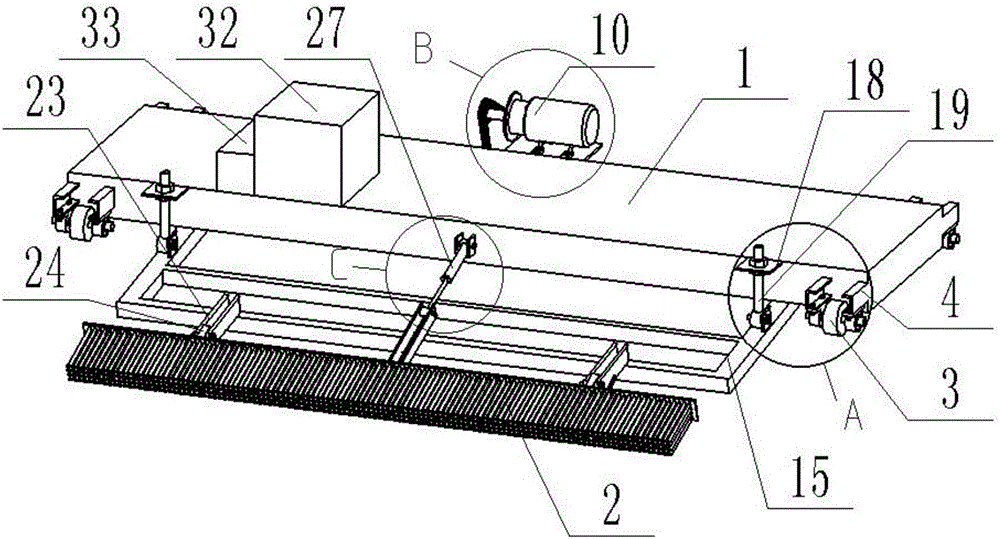

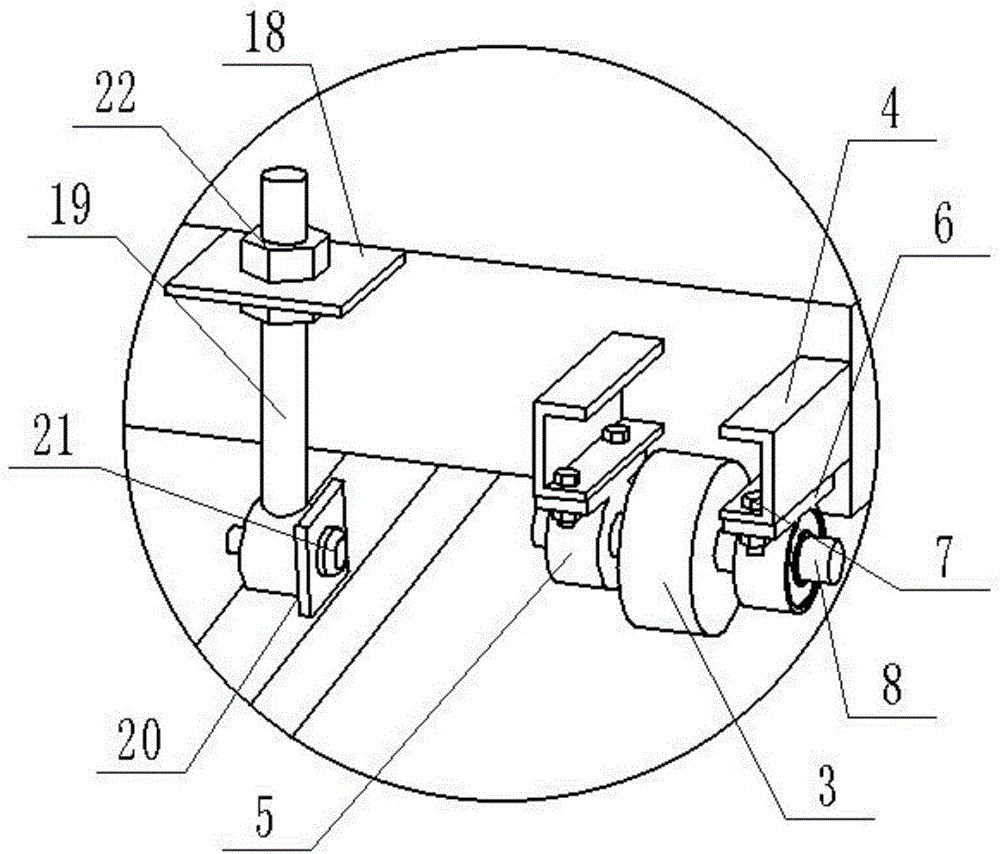

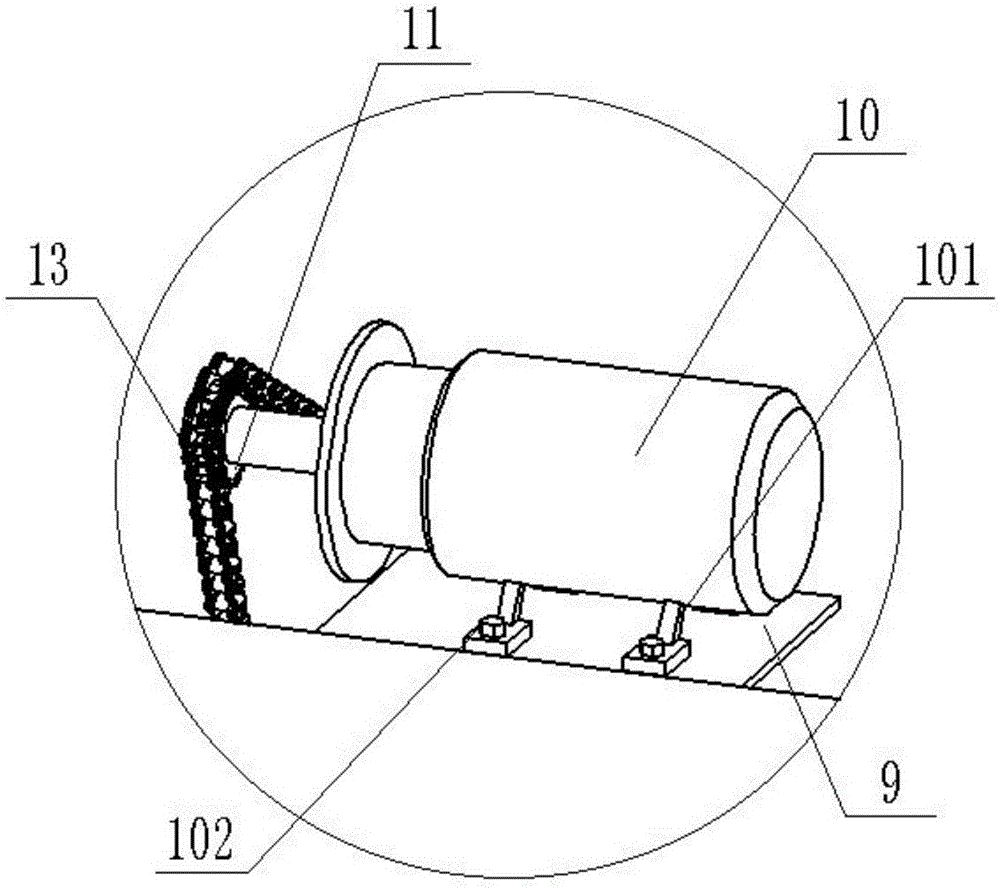

[0026] according to Figure 1 to Figure 6 As shown, a water treatment air flotation slag scraper includes a slag scraper body 1, a scraper 2, and a wheel 3. The wheels 3 are located on the front and rear sides of the slag scraper body 1. Axle 8, support frame 4 is provided on the left and right sides above the wheel 3 on the body 1 of the slag scraper, the wheel shaft 8 is supported on the support frame 4, and a travel switch I14 is provided on the support frame 4, the rear side of the body 1 of the slag scraper A motor 10 is provided, and the output shaft of the motor 10 is provided with a sprocket I11, and the position corresponding to the sprocket I11 on the wheel shaft 8 is provided with a sprocket II12, and the sprocket I11 and the sprocket II12 are connected by a chain 13, so A movable frame 15 is provided under the slag scraper body 1, the rear end of the movable frame 15 is connected to the lower end surface of the slag scraper body 1, and a support plate II 18 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com