Microchannel heat exchanger for air conditioner of passenger car

A micro-channel heat exchanger and air-conditioning technology, which is applied in the direction of evaporator/condenser, lighting and heating equipment, refrigeration components, etc. Poor reliability and other problems, to achieve the effect of light weight, simple structure and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

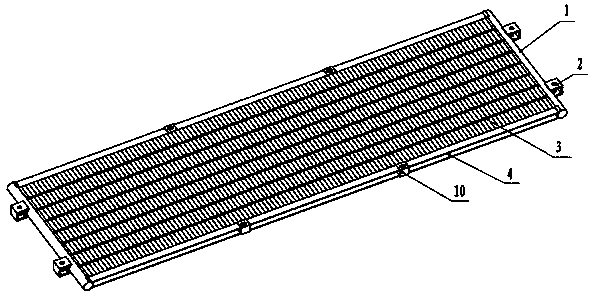

[0032] A specific embodiment of a microchannel heat exchanger for passenger car air conditioners according to the present invention will be further described below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

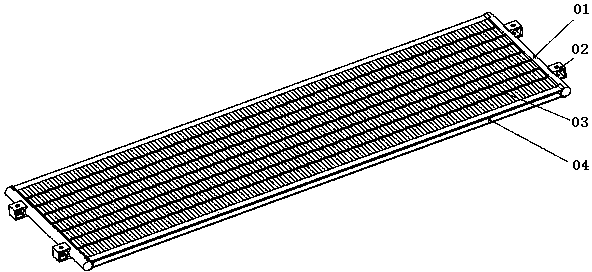

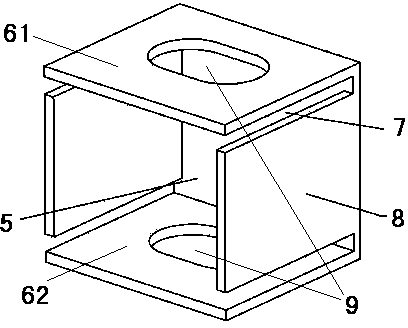

[0033] see figure 2 . A microchannel heat exchanger for passenger car air conditioners, comprising a header 1, a mounting bracket 2, a flat tube 3, a side plate 4 and a fixing device 10. Two headers 1 that are parallel to each other and separated from each other are used; two mounting brackets 2 are respectively arranged on the headers 1; two ends of several flat tubes 3 parallel to each other are connected (welded) on the Between the two collecting pipes 1, the flat tube 3 is communicated with the inner cavity of the collecting pipe 1; the two collecting pipes 1 and the two side plates 4 are made into a rectangular frame structure. These are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com