Novel tunnel non-contact deformation monitoring method

A deformation monitoring, non-contact technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of high human resource requirements, affect the construction progress, take 10 minutes or even longer, and achieve human resource consumption Minimize and avoid data loss and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

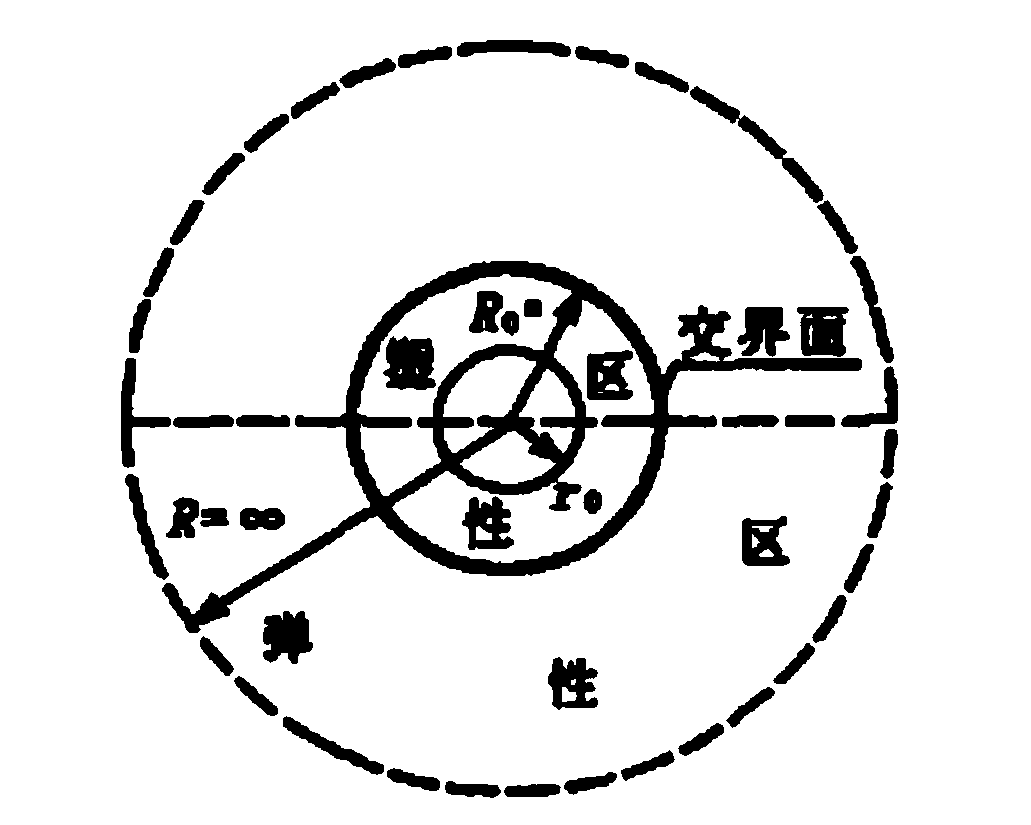

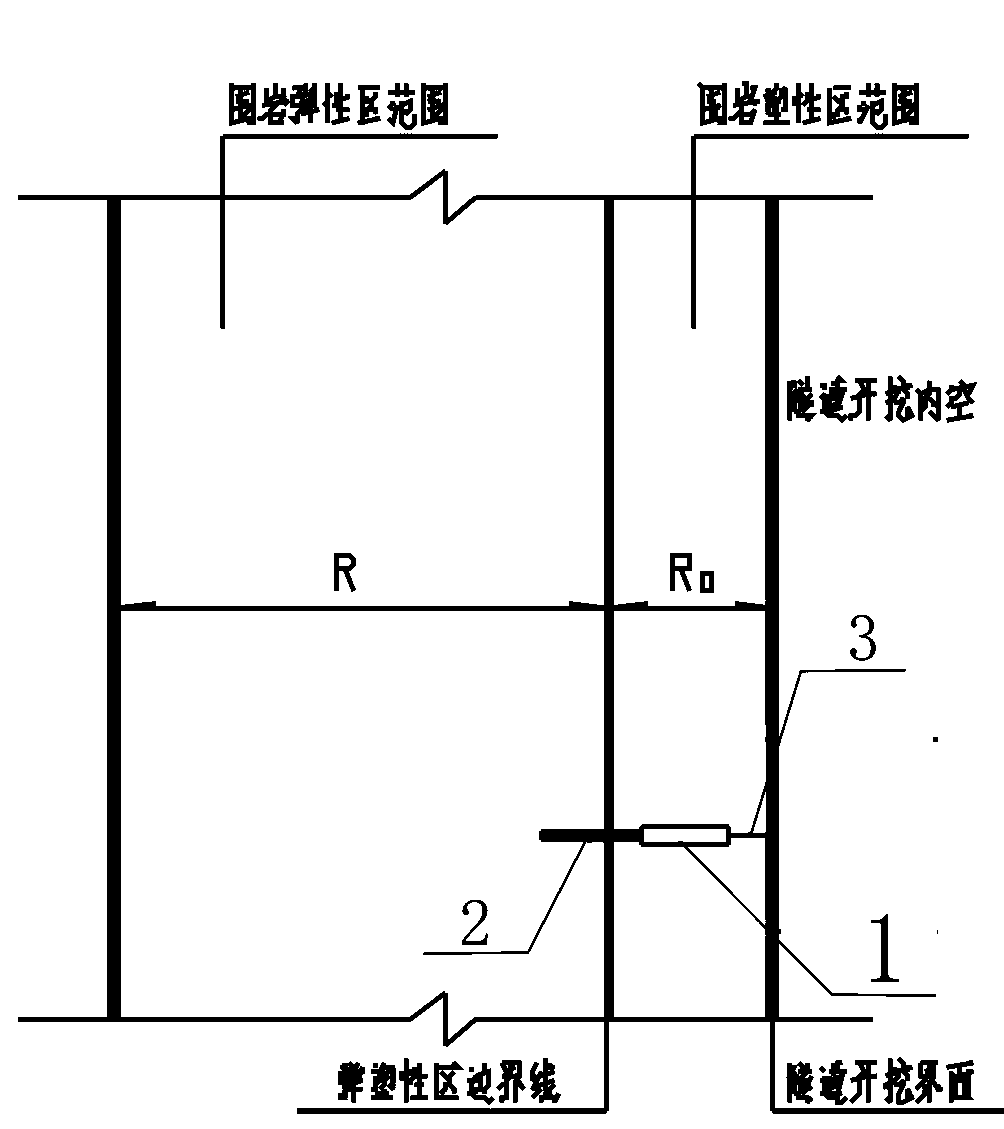

[0036] Embodiment 1: as figure 1 and figure 2 As shown, the deformation of the surrounding rock around the tunnel after excavation can be divided into an elastic zone and a plastic zone, and the deformation monitoring data used to guide design and construction is mainly the plastic deformation of the surrounding rock.

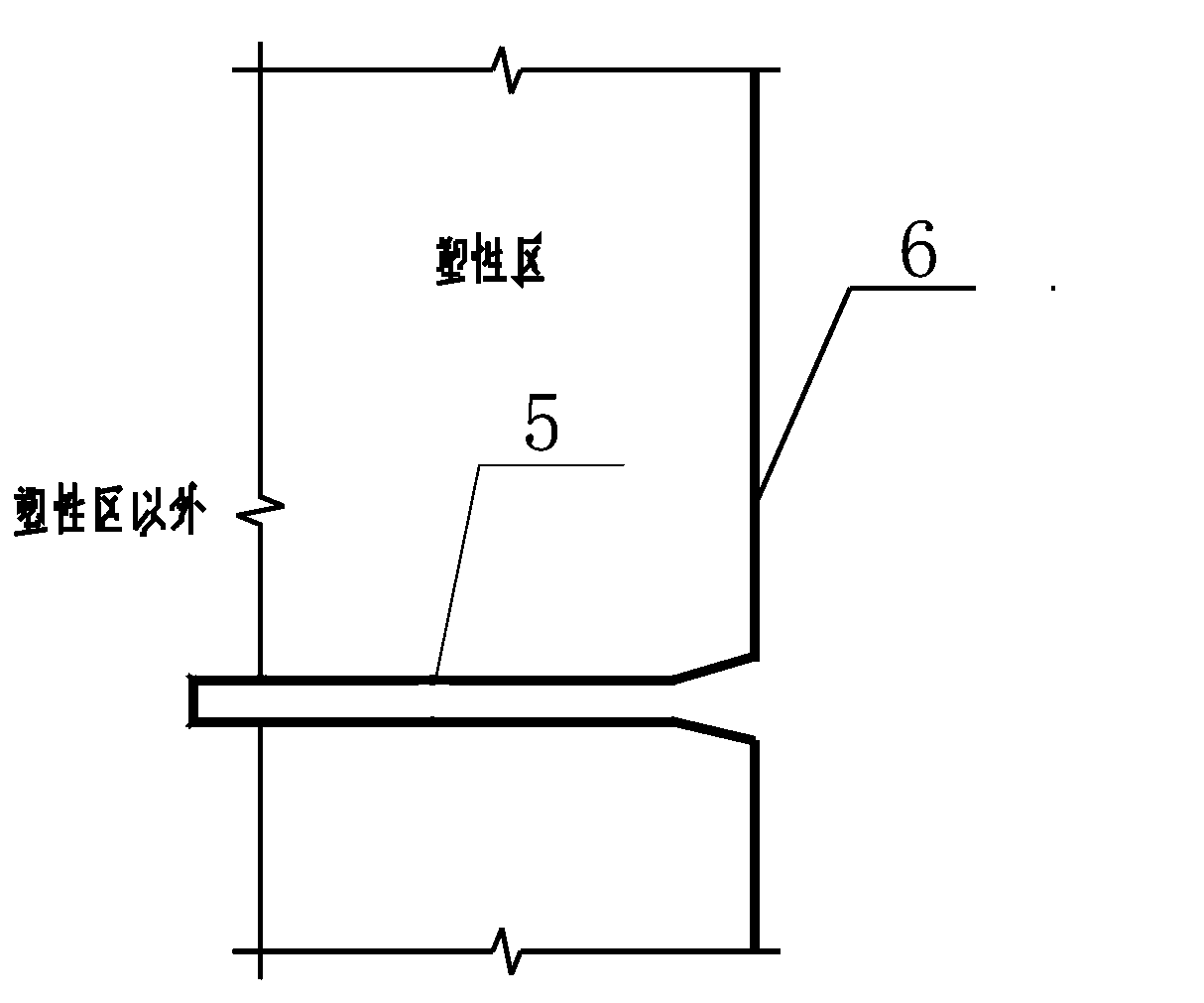

[0037] like figure 2 As shown in , the anchor end of the displacement sensor is embedded in the elastic zone through the interface of the elastic-plastic zone and fixed. Fix the top of the telescopic probe at the sensor end, that is, the active point, to the tunnel excavation interface. Therefore, the deformation value in the R0 range between the tunnel excavation interface and the elastic-plastic zone interface can be effectively tested.

[0038] Before the sensor is buried, it is necessary to first determine the boundary of the plastic zone of the tunnel, that is, the value of R0. The unified strength criterion can consider the influence of the intermedi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com