Once-through boiler unit set coordinated control system and design method thereof

A coordinated control system, once-through boiler technology, applied in general control systems, control/regulation systems, adaptive control, etc., can solve problems such as large parameter fluctuations, poor unit load adaptability, and difficulty in guaranteeing fuel-water ratio coefficients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

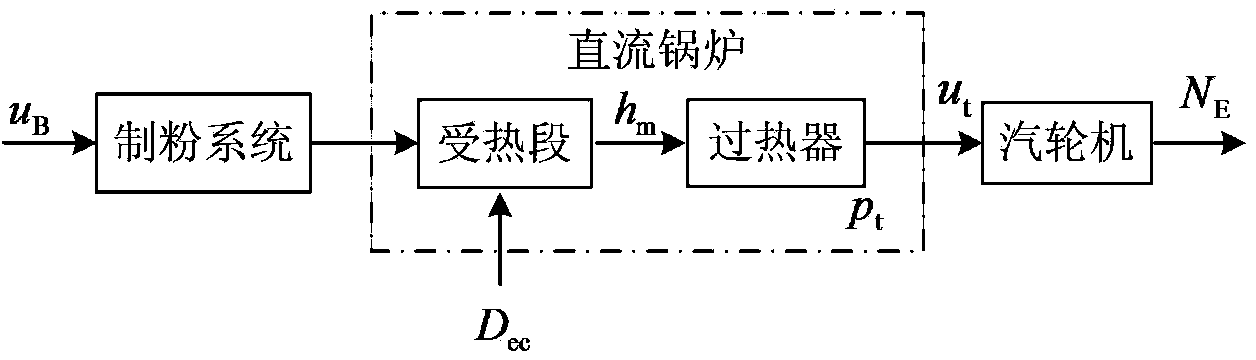

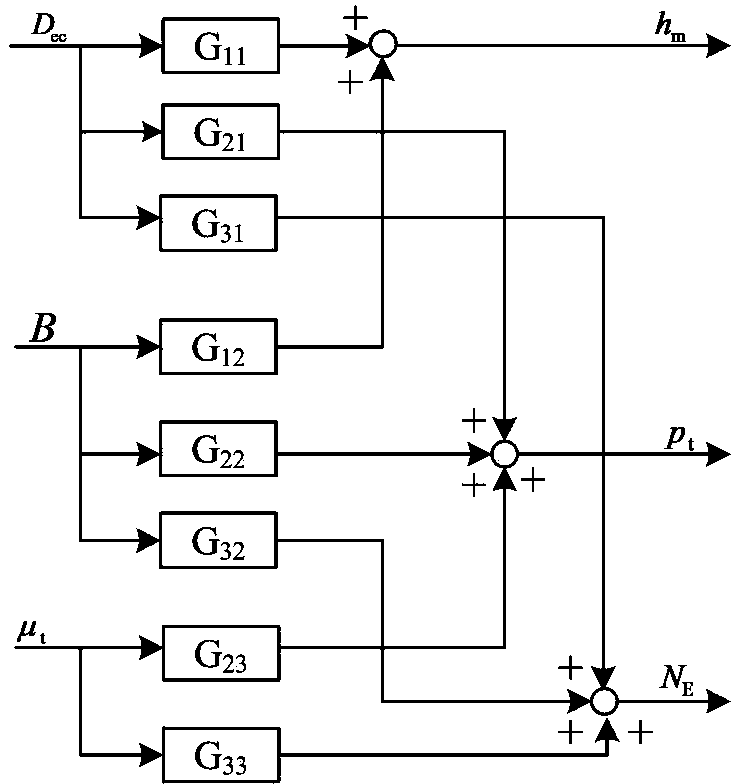

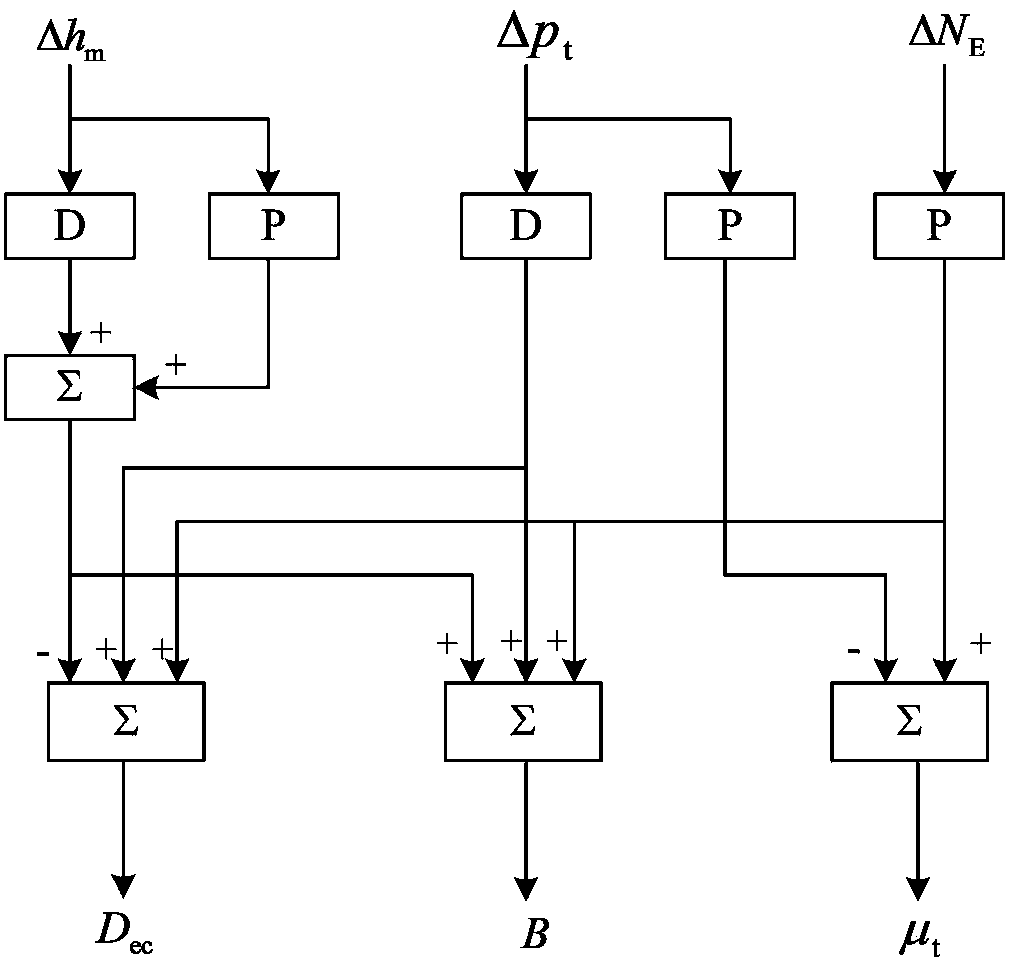

[0034] The present invention proposes a once-through boiler unit unit coordination control system, such as Figure 8 As shown, the control system is composed of a pulverizing system, a once-through boiler, a steam turbine, a power sensor, a pressure sensor, an enthalpy sensor, three PI controllers and a decoupling compensator; among them, the once-through boiler is divided into a heating section and a superheating section; The pulverized powder system is connected to the heating section in the once-through boiler, the heating section is connected to the superheating section, and the superheating section is connected to the steam turbine;

[0035] One end of the power sensor is connected to the steam turbine, and the other end is connected to the input end of the first PI controller, and the detected current turbine power N E and initial turbine power N E0 together to the input of the first PI controller; the output of the first PI controller is connected to the first input of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap