Electrical connector and method for producing same

An electrical connector and connector technology, which is applied in the direction of contact manufacturing, connection, clamping/spring connection, etc., can solve the problems of high contact resistance and high resistance of electrical connectors, and achieve the purpose of suppressing sliding distance and reducing sliding wear , The effect of improving electrical reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

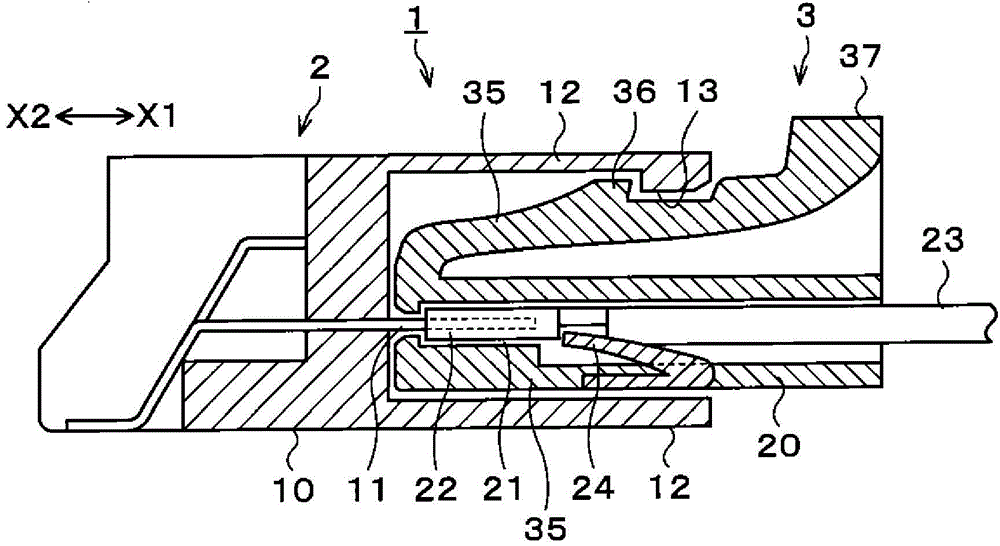

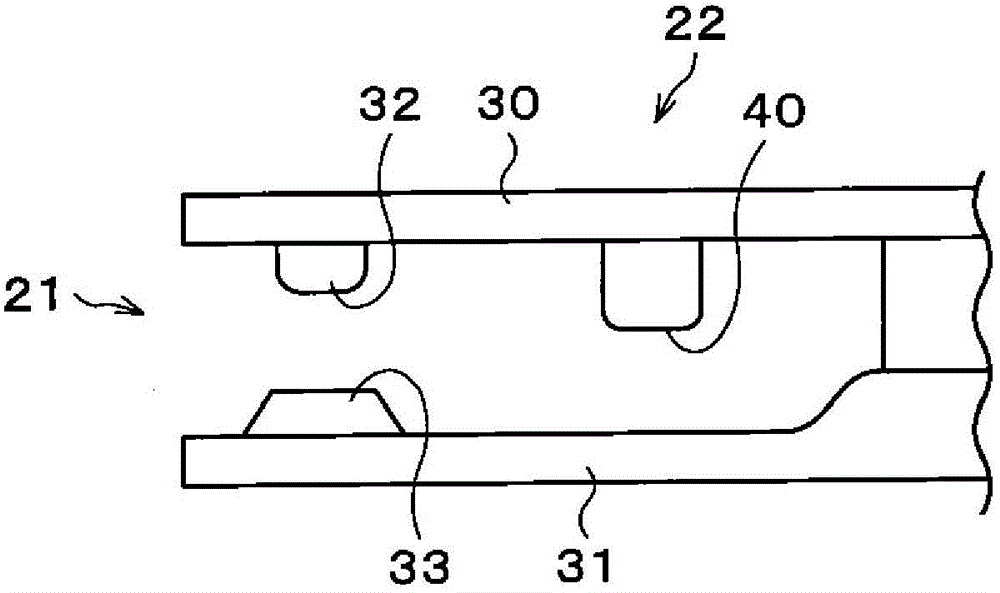

[0036] Hereinafter, an example of the embodiment of the present invention will be described with reference to the drawings. In addition, in this specification and drawings, the same code|symbol is attached|subjected to the component which has substantially the same functional structure, and repeated description is abbreviate|omitted. Such as figure 1 As shown, the electrical connector 1 of this embodiment has a male connector 2 and a female connector 3 that can be freely engaged and disengaged from each other.

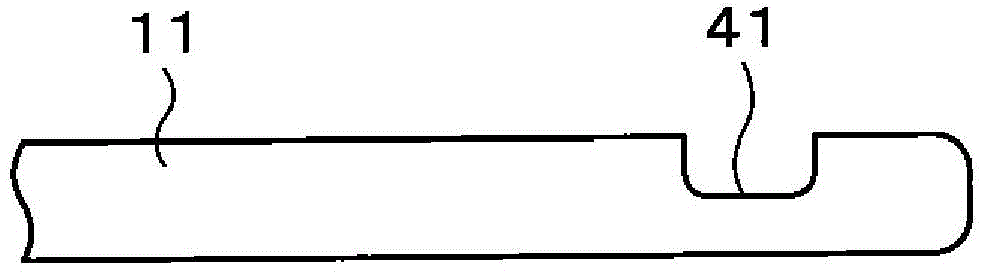

[0037] figure 1 The male connector 2 shown on the left has a structure in which a male terminal 11 made of a conductive material protrudes from the front end surface of the male-side resin molded part 10 . A cylindrical male side cover 12 is provided on the male side resin molded part 10 so as to surround the circumference of the male joint 11 . A male locking lock 13 is provided on the inner peripheral surface of the male side cover 12 facing inward.

[0038] on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com