Contact lens box capable of automatically taking lenses

A contact lens case and lens technology, applied in accessories, clothing, applications, etc., to achieve the effects of light weight, safe use and operation, and easy portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

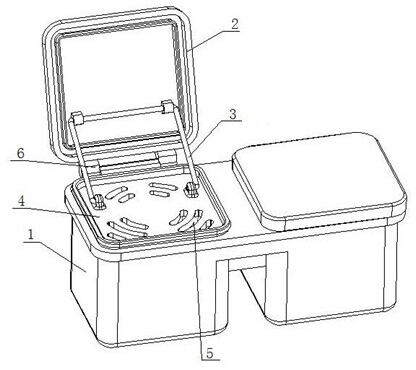

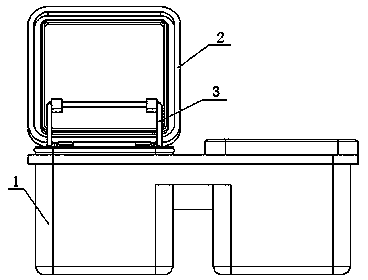

Image

Examples

Embodiment 1

[0045] Such as Figure 8 and Figure 9 The connecting mechanism 3, the shelf 4 and the limiting block 7 of the present invention are integrally formed, wherein the connecting mechanism 3 and the box cover 2 are connected by a flexible connecting rope 9 and the limiting block 7 is designed as a right triangle (saving raw materials); The integrally formed structure of this embodiment is easy to process and install, high in production efficiency, and low in cost. The shelf 4 can be pulled out by using the flexible connecting rope 9 when the lid 2 is opened. After closing, the shelf 4 falls to the initial position by its own gravity.

Embodiment 2

[0047] Such as Figure 10 The connecting mechanism 3, the shelf 4 and the limit block 7 of the present invention are integrally formed, wherein the connecting structure 3 is strip-shaped and grooves 10 are evenly arranged on one side, and the box cover 2 is connected to the box body through a cylindrical connecting piece 12. 1 connection, the transmission tooth 11 is set on the cylindrical connecting piece 12; in this embodiment, the box cover 2 is opened, and the connecting mechanism 3 in contact with it is lifted out of the box body through the groove 10 by using the driving tooth 11 set on the cylindrical connecting piece 12 1. When closing, the transmission gear 11 cooperates with the groove 10 to lower the box body 1 to the initial position, and the structure is simple and practical.

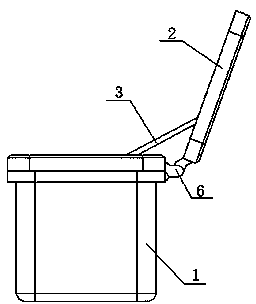

Embodiment 3

[0049] Such as Figure 11 and Figure 12 The connecting mechanism 3, the shelf 4 and the limit block 7 of the present invention are integrally formed as shown, wherein the connecting structure 3 is an inverted "L" shape, and one end of the lifting rod 13 is connected to the box cover 2, and the other end is set in a circle. The rod 13 and the box cover 2 are arranged obliquely, and the angle of inclination is 10°-30°; The shelf 4 is pulled out of the box body 1, and when closed, the shelf 4 falls back to the initial position by its own gravity, wherein the lifting rod 13 is made of corrosion-resistant materials; further as Figure 13 As shown, a limit guide groove 14 is provided on the inverted "L"-shaped connecting mechanism 3, so that there will be no sliding phenomenon during the working process of the lifting rod 13, and the use is safe and reliable.

[0050] Such as Figures 7 to 13 As shown, during the opening and closing process of the glasses case, the shelf 4 moves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com