Fixtures for thin-walled parts with lightening holes

A technology of thin-walled parts and weight-reducing holes is applied in the field of fixtures for thin-walled parts with weight-reducing holes, which can solve the problems of waste, affecting production efficiency, easy deformation, etc., and achieves increased equipment investment, reasonable and reliable structural design, and deformation of parts. The effect of reducing the chance of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

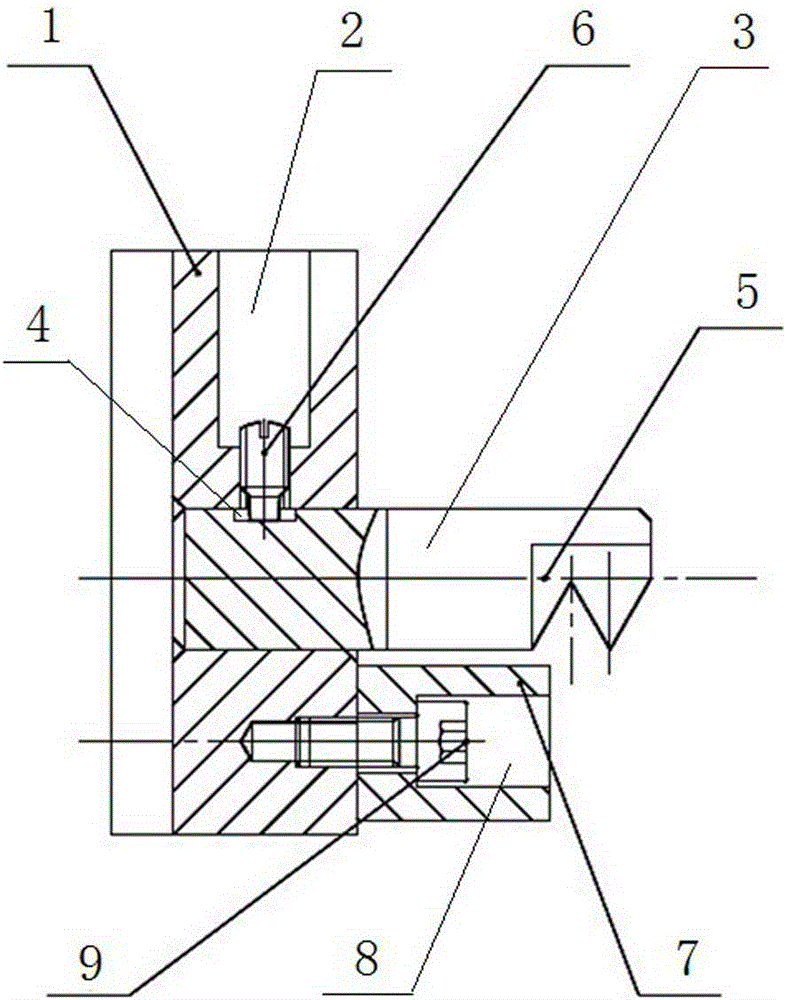

[0010] Fixtures for thin-walled parts with weight-reducing holes, including a rectangular connection base plate 1 connected to each hydraulic chuck female jaw, an adjustment hole is opened in the middle of the connection base plate 1, and one end surface of the connection base plate 1 is opened to communicate with the adjustment hole and Vertical stepped hole 2, a cylindrical chuck rod 3 is pierced in the adjustment hole, a keyway 4 opposite to the position of the stepped hole is opened on the side wall of one end of the chuck rod 3, and a clamping tooth is opened on the side wall of the other end of the chuck rod 3 Groove 5, the set screw 6 that is threadedly connected with it and contacts with the bottom end of keyway 4 is screwed in the step hole 2, and a positioning block 7 is arranged below the clamping alveolar 5, and a step hole I8 is provided on the position block 7, and a step hole I8 is provided in the step hole I8. Screwed with the fastening screw 9 that is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com