Linear two-way solenoid valve

A two-way solenoid valve, linear technology, applied in valve details, valve devices, multi-way valves, etc., can solve problems such as less than ideal control accuracy, high assembly process costs, and failure of the check valve core sealing function, and achieve assembly The process cost is relatively low, the assembly process cost is low, and the effect of easy and effective assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

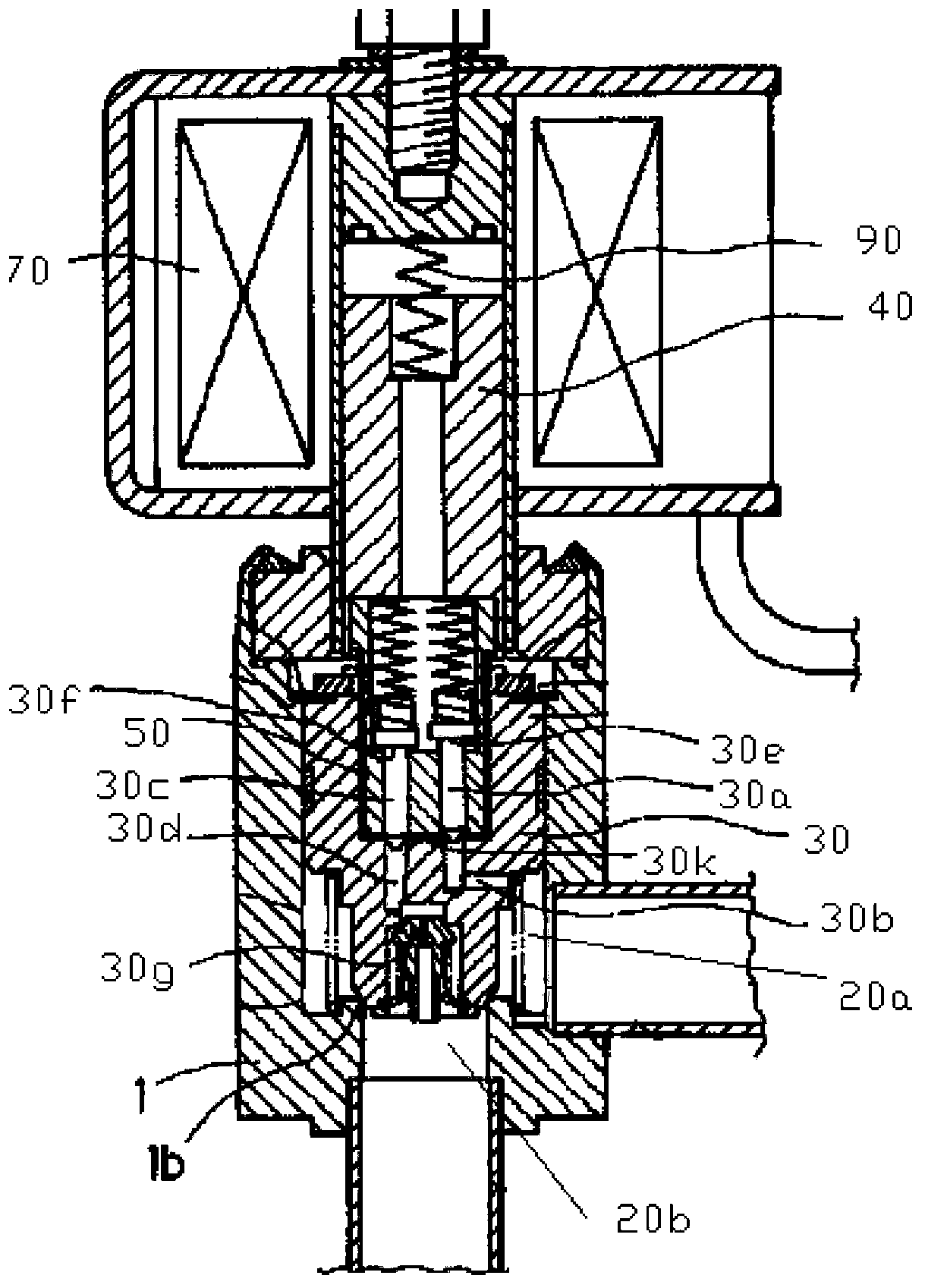

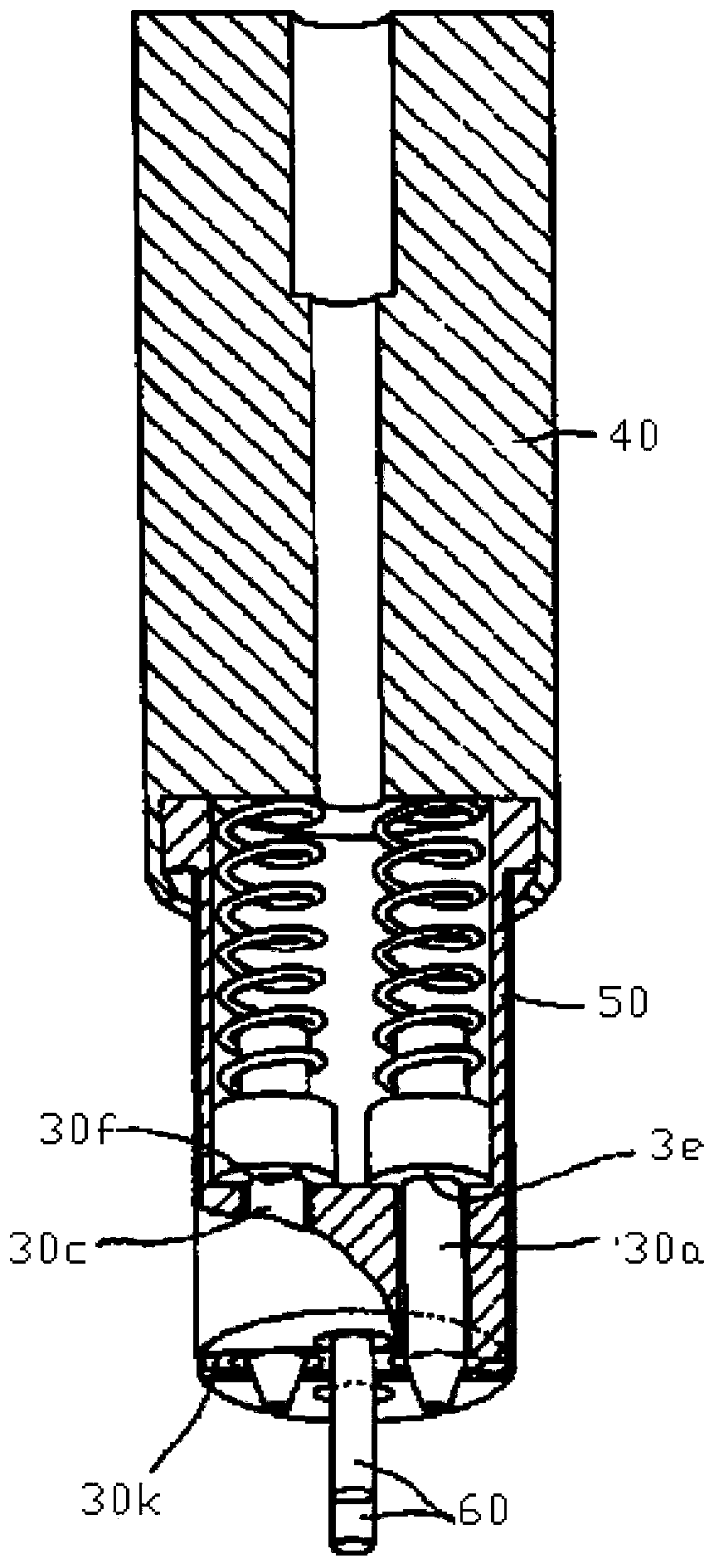

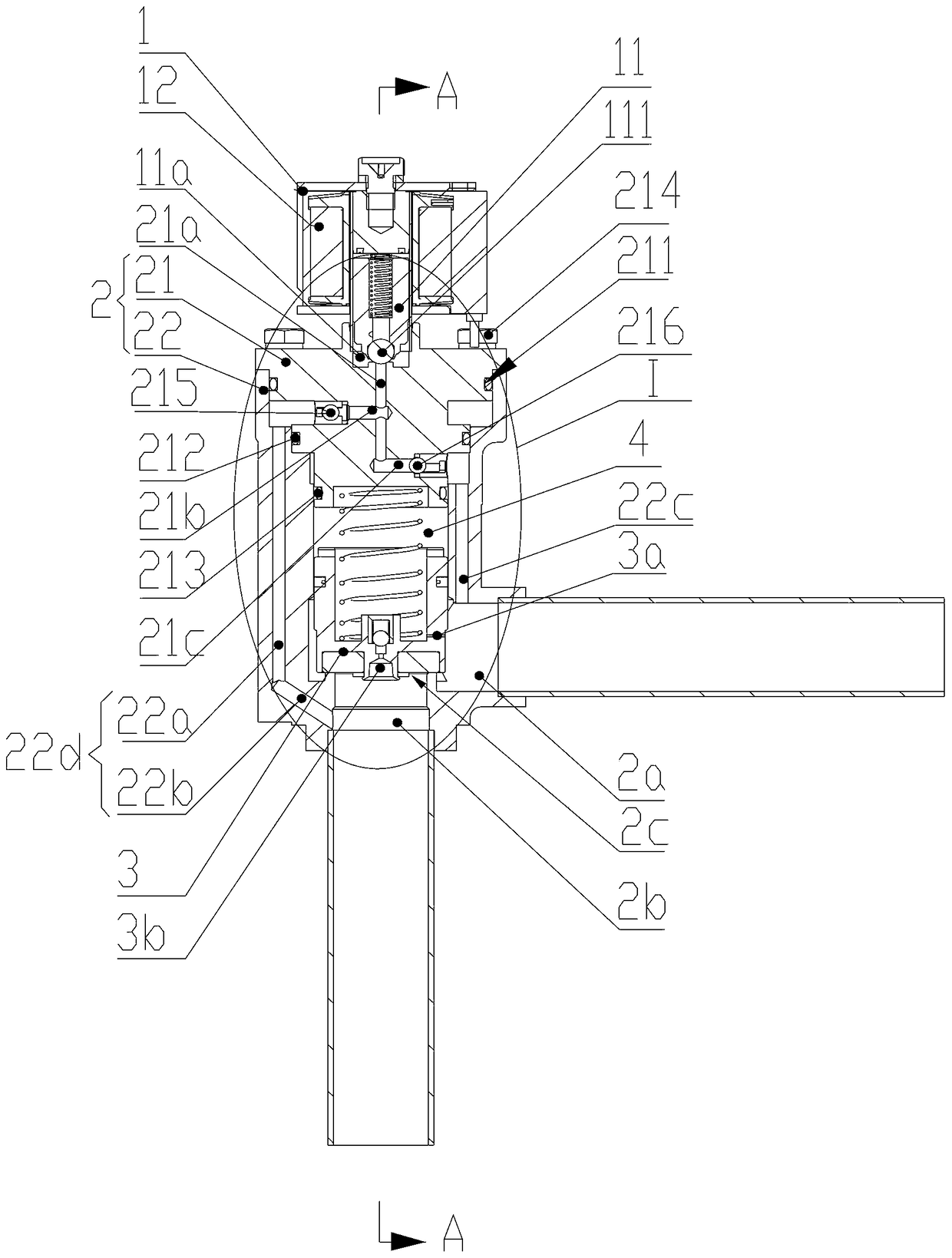

[0062] Please refer to Figure 3-8 , image 3 Axial sectional view of the first embodiment of the linear two-way solenoid valve provided for the invention; Figure 4 for image 3 Partial enlarged schematic diagram of part C in the middle; Figure 5 for image 3 A-A sectional view; Image 6 for image 3 Schematic diagram of the structure of the upper and middle valve body; Figure 7 for Figure 5 Schematic diagram of the structure of the upper and middle valve body; Figure 8 for image 3 The three-dimensional structure diagram of the upper and middle valve body.

[0063] The linear two-way solenoid valve has a main valve body 2 and a pilot valve body 11, and the main valve body 2 includes an upper valve body 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com