A bimetal sheet heat-collecting temperature-photosensitive automatic center-of-gravity adjustment device

A bimetallic, automatic adjustment technology, applied in the control/adjustment system, non-electric variable control, position/direction control and other directions, can solve the problems of energy consumption, untimely, complex mechanism, etc., and achieves low cost and convenient disassembly and assembly. , Precision and flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

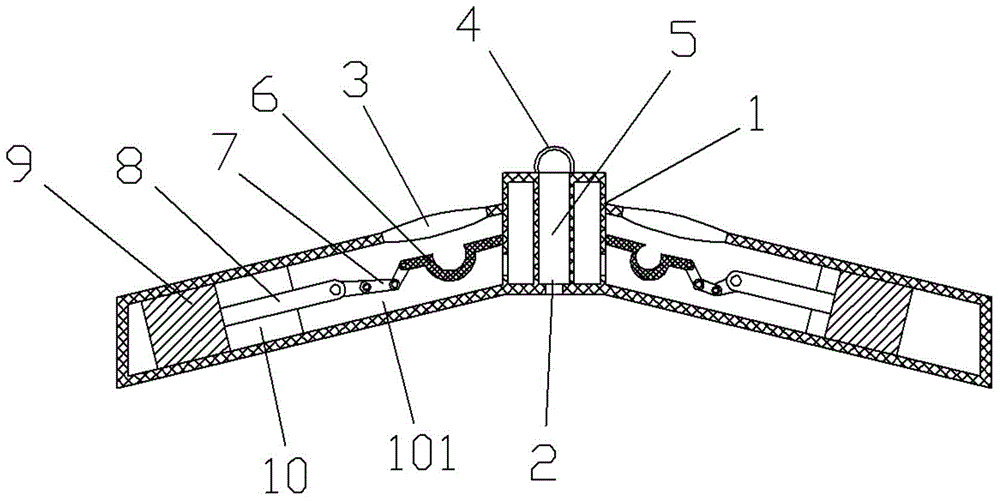

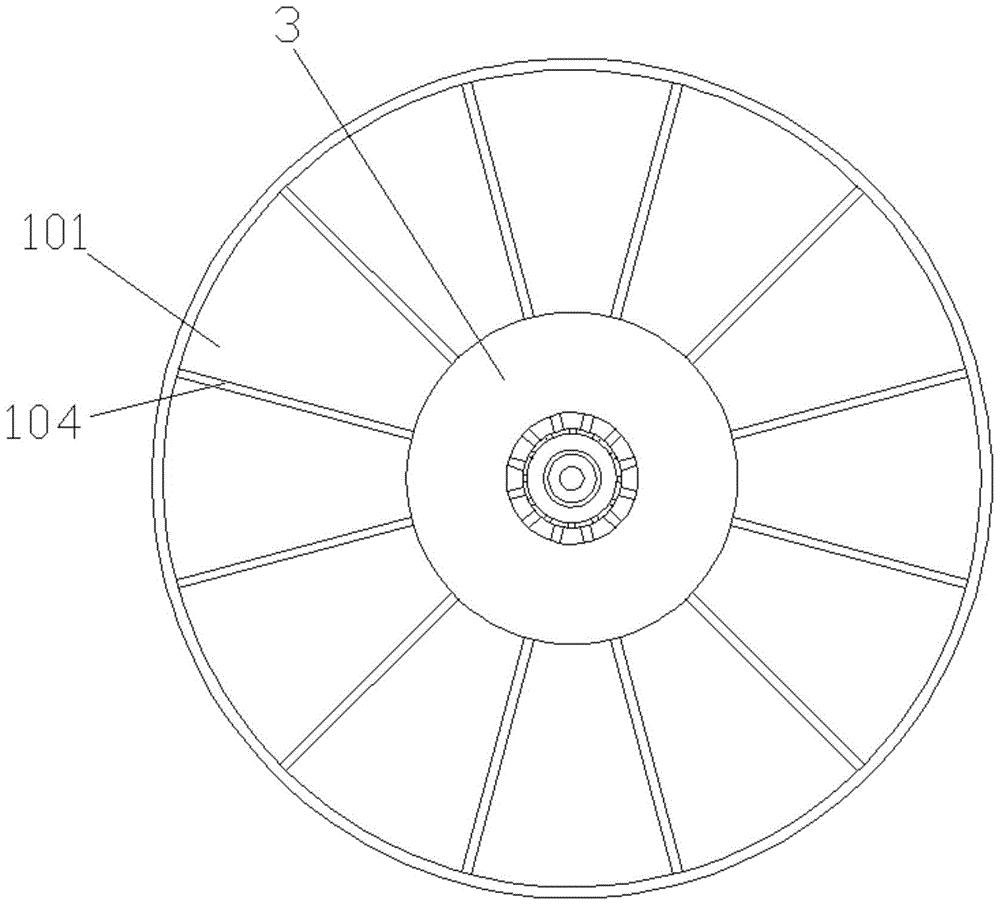

[0019] refer to figure 1 As shown, a bimetal heat-collecting type temperature-photosensitive automatic center-of-gravity adjustment device includes a box body 1, a central installation connection reserved position 2, a light-heat gathering ring 3, a vertical level indicator 4 and an installation avoidance position 5 , the box body 1 includes a split warehouse unit 101 and a unit partition wall 104, the vertical level indicator 4 and the installation avoidance position 5 are located in the middle of the device, and the split warehouse unit 101 is composed of a plurality of uniformly distributed units Composed, connected with each other to form a cone, each of the split chamber units 101 is provided with a piston movable chamber 10 and a bimetallic vigorous structure piece 6 inside, and a heavy piston block 9 that can move along the pi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap