Integrated inductor structure and method for manufacturing integrated inductor structure

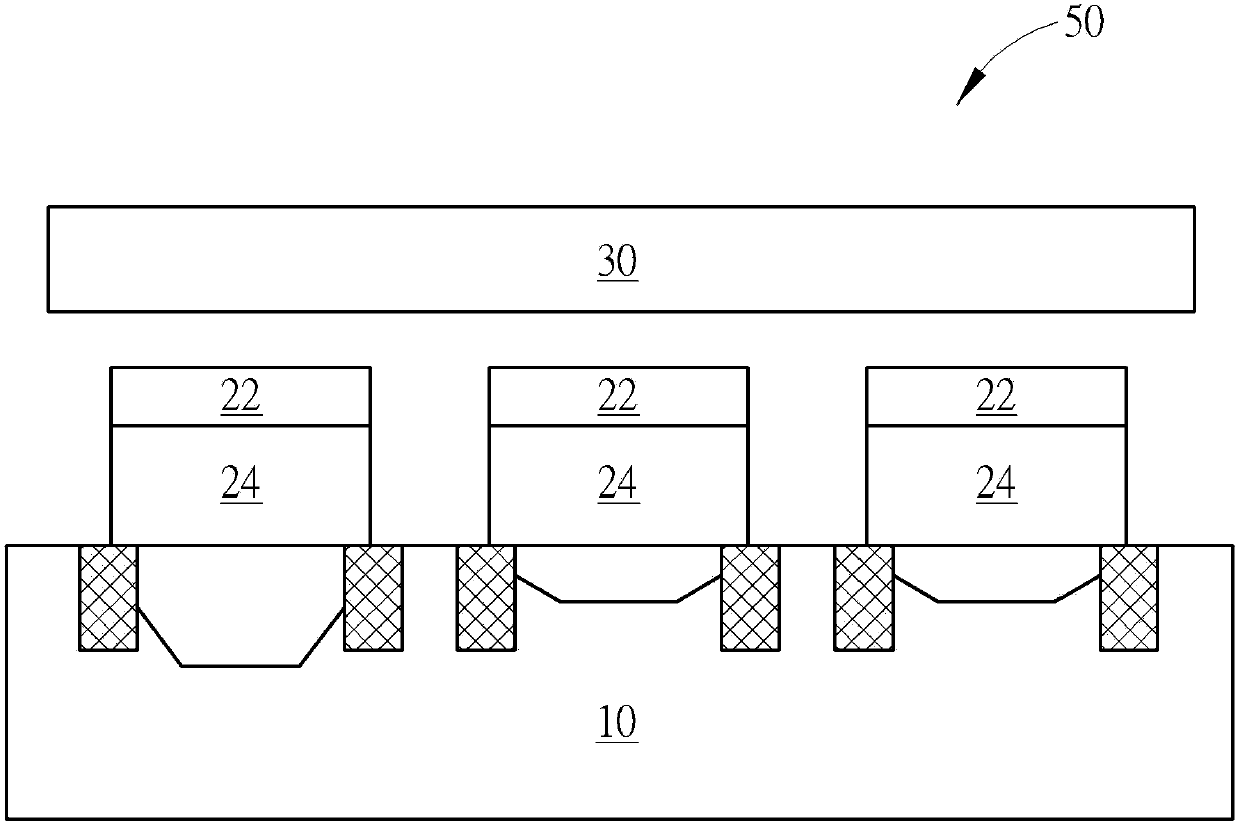

A technology of integrated inductance and manufacturing method, which is applied in the field of integrated inductance structure manufacturing, can solve the problems of poor blocking effect and inability to effectively reduce eddy current, and achieve the effect of complete blocking effect and improved quality factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0066] Please refer to Figure 4 , Figure 4 What is shown is a flowchart of a first embodiment of the method for manufacturing an integrated inductor structure of the present invention based on the aforementioned integrated inductor structure 200. If substantially the same result can be obtained, the steps in the process do not necessarily need to be followed. Figure 4 The sequence shown does not necessarily need to be sequential, that is, other steps may be inserted between these steps. The first embodiment of the method for manufacturing an integrated inductor structure of the present invention includes the following steps:

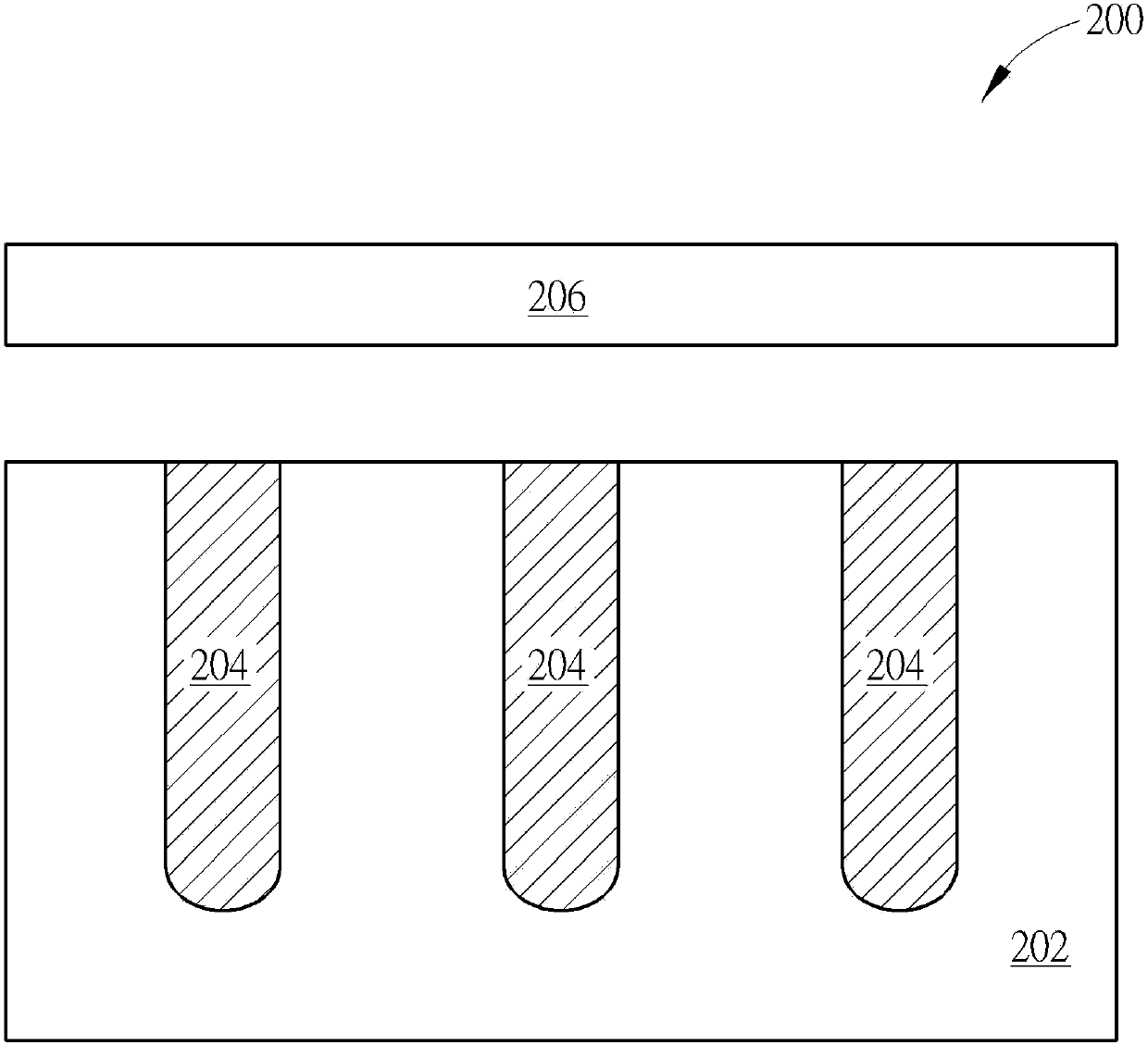

[0067] Step 400: Form a semiconductor substrate.

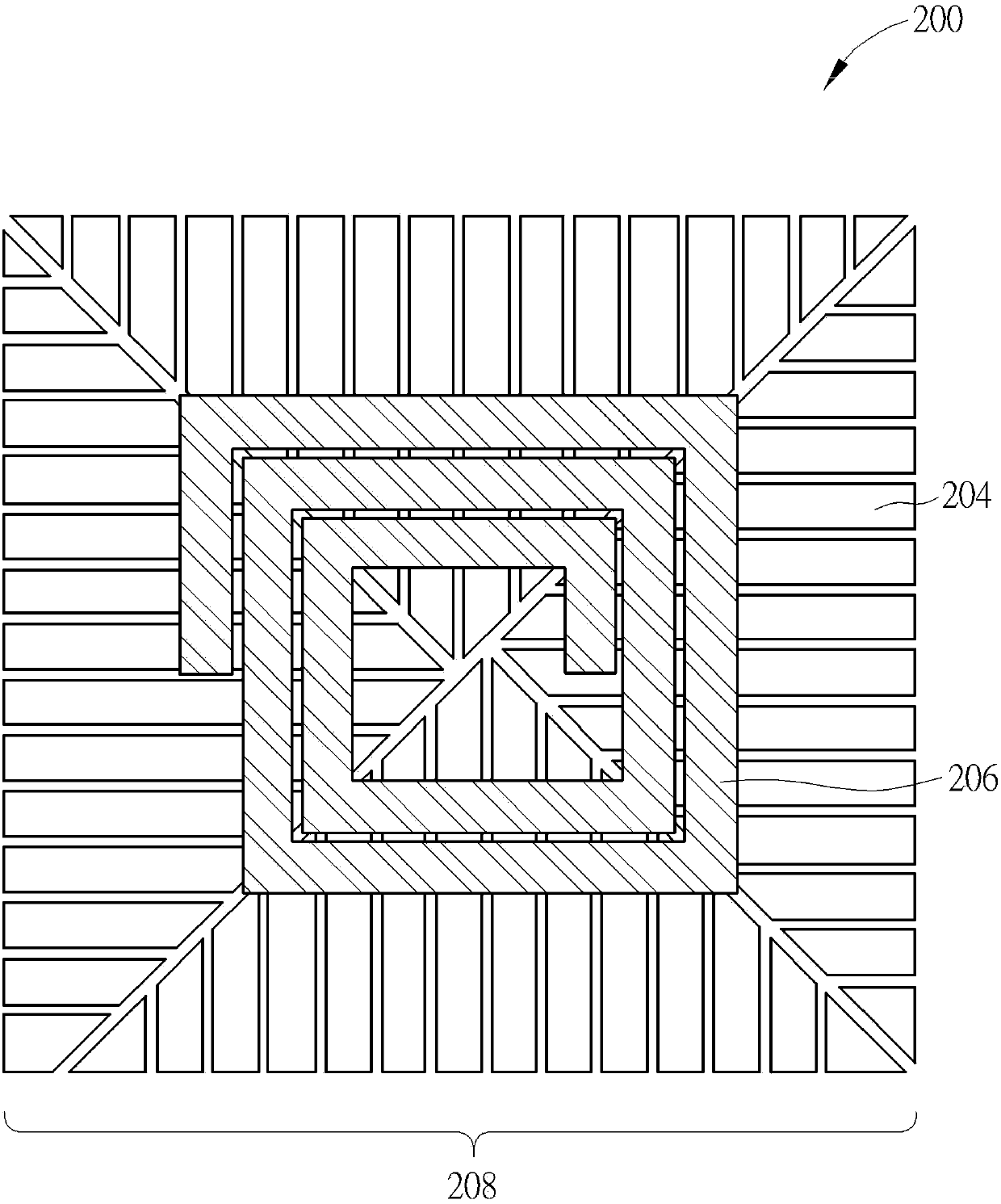

[0068] Step 402: Form a plurality of deep trenches in the semiconductor substrate, and arrange the plurality of deep trenches into a specific pattern.

[0069] Step 404 : Fill a metal material in the plurality of deep trenches to form a patterned ground shield.

[0070] Step 406 : Form an inductor...

no. 4 example

[0081] Please refer to Figure 13 , Figure 13 What is shown is a flowchart of a fourth embodiment of the integrated inductor structure manufacturing method of the present invention based on the above-mentioned integrated inductor structure 700. If substantially the same result can be obtained, the steps in the process do not necessarily need to be followed. Figure 13 The sequence shown does not necessarily need to be sequential, that is, other steps may be inserted between these steps. The fourth embodiment of the integrated inductor structure manufacturing method of the present invention includes the following steps:

[0082] Step 800: Form a semiconductor substrate.

[0083] Step 802: Form an inductor over the semiconductor substrate.

[0084] Step 804 : Form a redistributed metal layer with a specific pattern on the inductor to form a patterned ground shield.

[0085] Please note that the above-mentioned embodiments are only used as illustrations of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com