A dual-purpose fertilizer seeder for wheat and corn

A seeder and corn technology, applied in fertilizers and sowing equipment, etc., can solve the problems of single-function wheat fertilization and seeding, unfavorable agricultural mechanization promotion, and high cost, and achieve the effects of improving passability, saving planting costs, and preventing straw congestion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further elaborated below through specific embodiments in conjunction with the accompanying drawings.

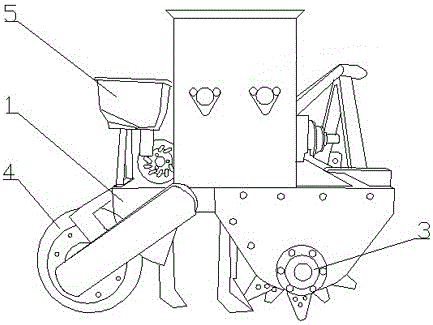

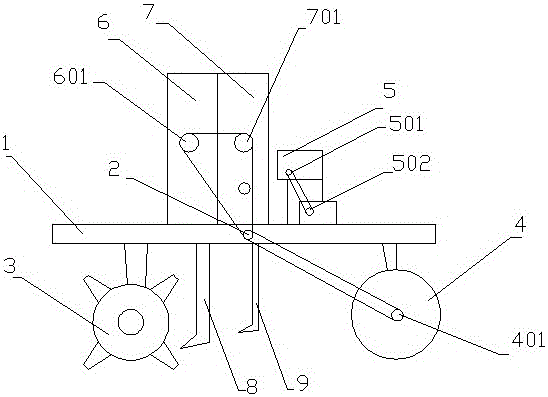

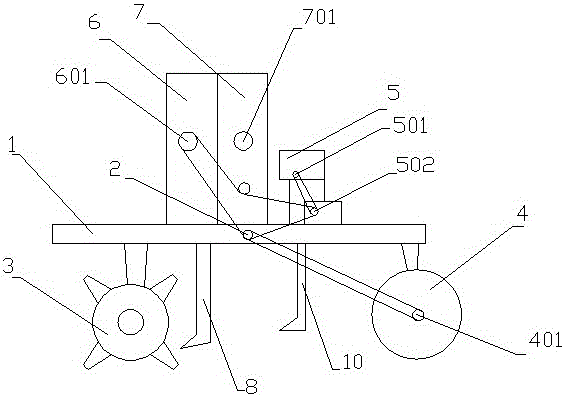

[0021] As shown in the figure, a dual-purpose fertilizing seeder for wheat and corn. The tractor pulls the frame to drive the seeder forward. With the forward direction of the seeder as the front, a ditching mechanism 3 is set at the front of the frame 1. The rear part of the frame is provided with a pressing wheel 4 for covering soil, and the fertilization and seeding assembly is arranged on the frame 1. The drive shaft I2 of the fertilization and seeding assembly is connected to the rotating shaft 401 of the pressing wheel 4 through a chain. The fertilization and seeding assembly includes a wheat seeding box 7. Fertilizer box 6 and a plurality of corn precision sowers 5, wherein the corn precision sowers 5 are installed above the frame 1 according to the required corn sowing row spacing, and the corn sowing shaft 501 on the corn precision...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com