Filter part

A filter and component technology, applied in the field of valve manufacturing equipment, can solve the problems of lack of elasticity, anti-vibration, and the inner wall anti-corrosion layer is not easy to spray, easy to fall off, etc., to enhance the filtering and adsorption effect, protect the inner wall from corrosion and damage, and install it stably. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

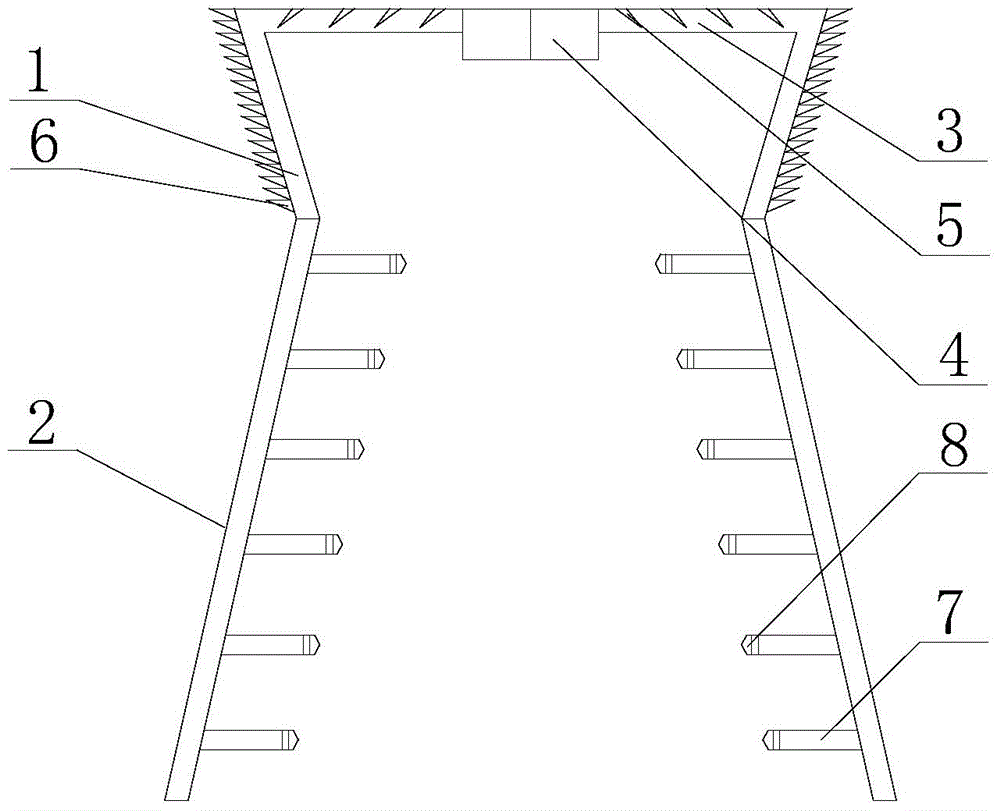

[0015] A filter component, which includes an upper inner sleeve 1, a lower inner sleeve 2 and a top inner sleeve 3, and the upper inner sleeve 1, lower inner sleeve 2 and top inner sleeve 3 are connected to the inner threaded stainless steel filter valve body fit, the outer layer of the upper inner sleeve 1 is provided with the thread 6 consistent with the internal thread stainless steel filter valve body, the center of the top inner sleeve 3 is provided with a top platform 4, and the upper inner sleeve 3 The surface is provided with a plurality of wedge-shaped grooves 5, and the wedge-shaped grooves 5 are evenly distributed. The inner wall of the lower inner sleeve 2 is provided with a plurality of filter tentacles 7, and the top of the filter tentacles 7 is provided with an adsorption device 8.

[0016] Further, the wedge-shaped groove 5 protrudes outward.

[0017] Further, the filtering tentacles 7 are evenly distributed.

[0018] Further, there are 20-120 filtering tentac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com