Adjustable cut-off machine

A cutting machine, adjustable technology, applied in the field of kitchen supplies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

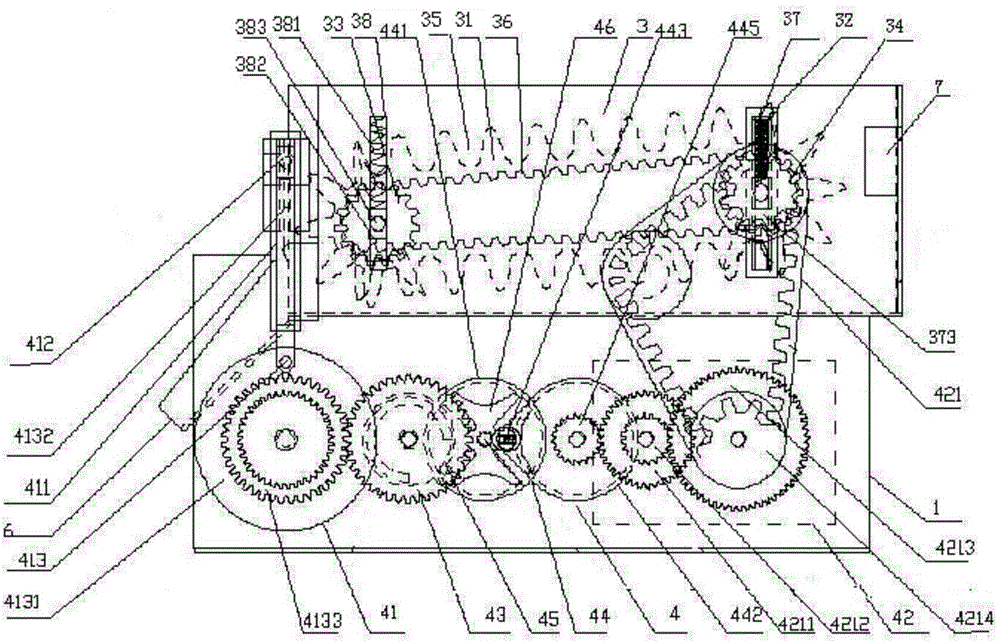

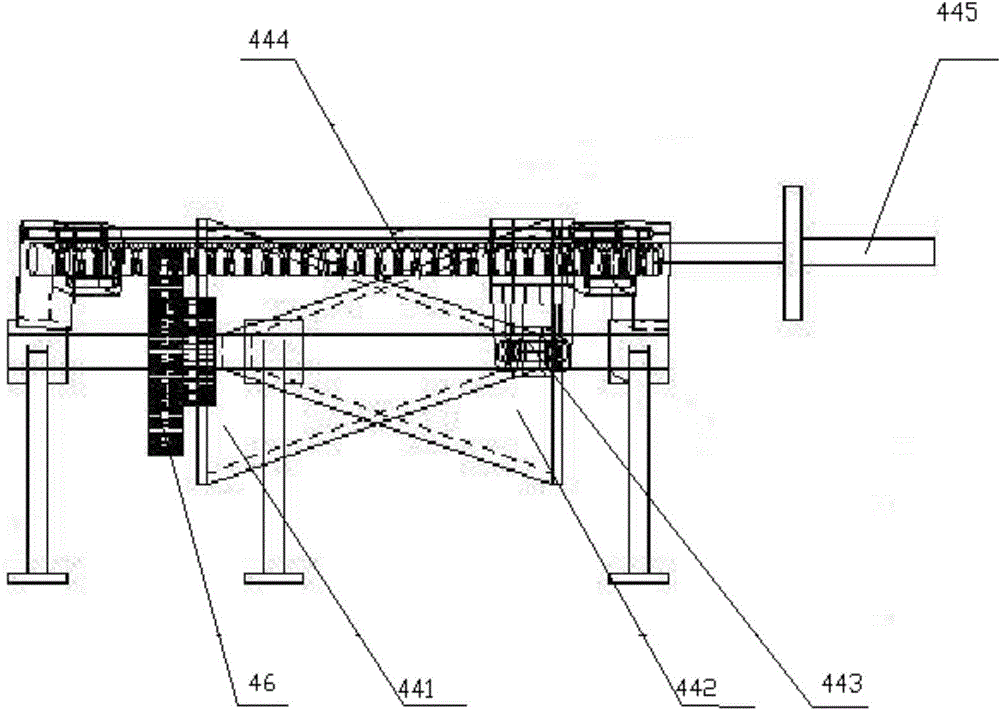

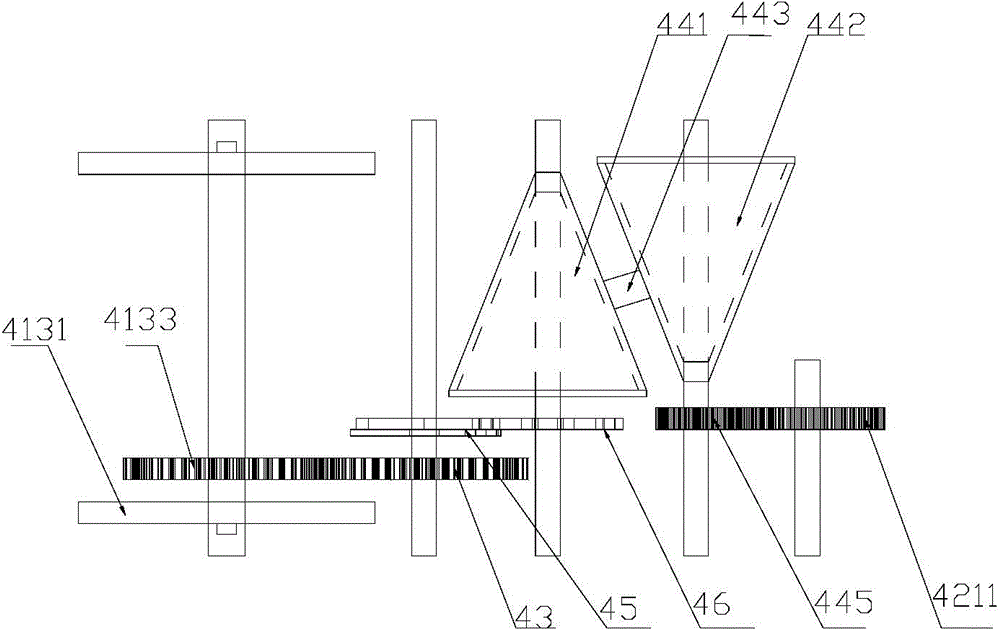

[0023] Such as Figure 1 to Figure 5 As shown, an adjustable cutting machine includes a frame 1, and the frame is provided with a knife body 2, a material conveying device 3 and a driving device 4, and it is characterized in that the driving device 4 includes a The cutter body drive unit 41 for the cutter body 2 reciprocating up and down, the raw material drive unit 42 for driving the raw material conveying device 3 and the main shaft 43 connected with the motor, the main shaft 43 is used for the described The cutter body driving unit 41 and the raw material driving unit 42 provide driving force, and a speed change unit 44 is also arranged between the main shaft 43 and the raw material driving unit 42, wherein the driving device also includes a sheave mechanism, and the The speed change unit 44 is connected to the main shaft 43 through a sheave mechanism, and the sheave mechanism includes a notch disc 45 coaxially connected with the main shaft 43, and a sheave 46 coaxially con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com