Cross rod end socket for railway wagon x-bracing bogie

A technology for cross bracing and railway freight cars, applied in the directions of bogies, railway car body parts, transportation and packaging, etc., can solve the problems of difficult inspection of blind holes, large economic losses, scrapping of cross rods, etc., and strengthen the fastening effect. , Strong anti-drop function, high maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

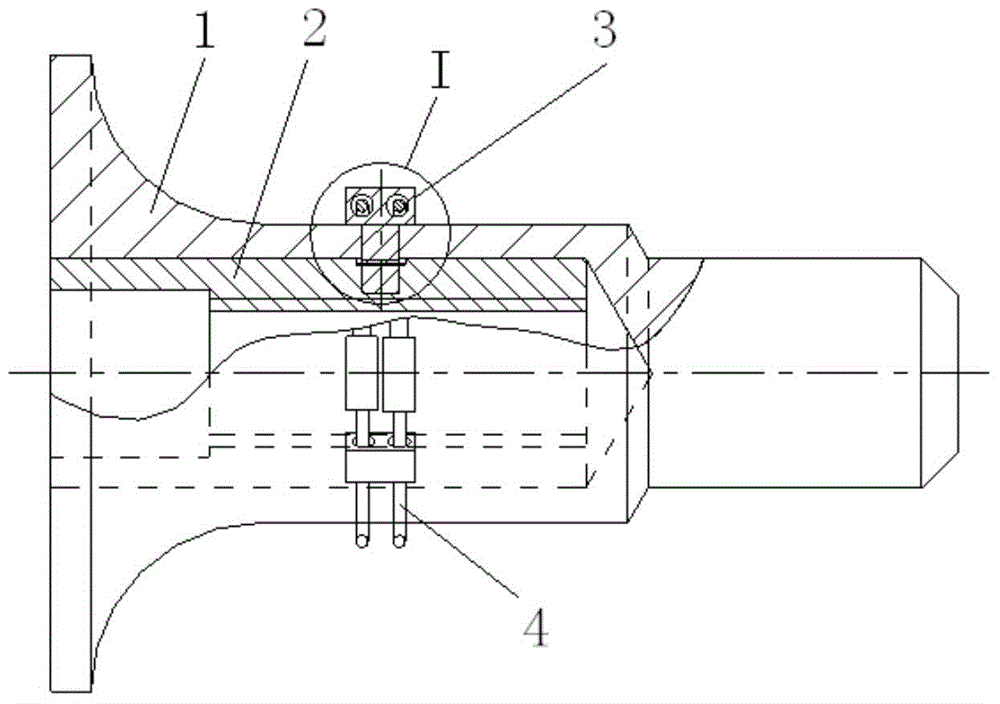

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

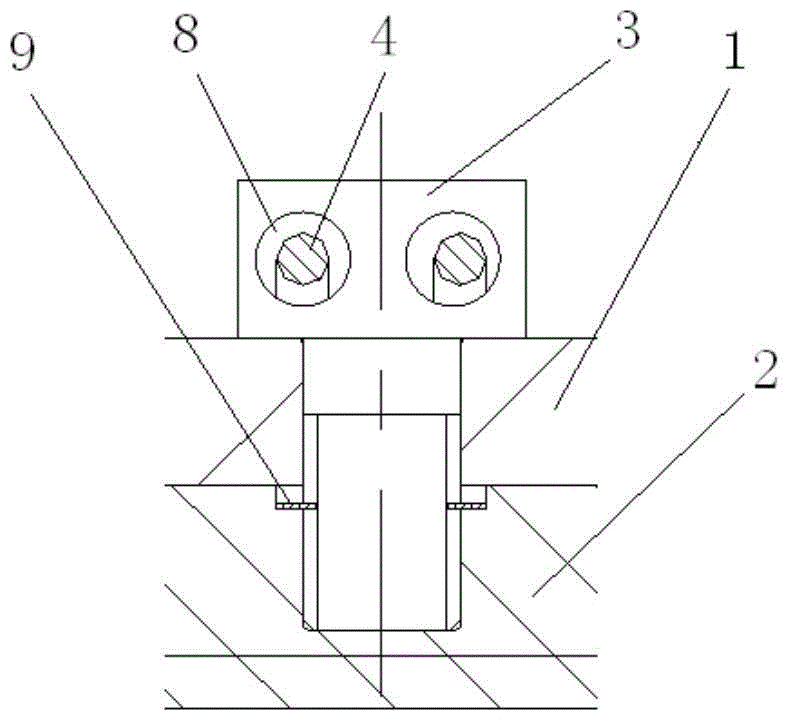

[0023] Such as figure 2 , image 3 As shown, the present invention includes a terminal body 1 , a threaded inner sleeve 2 , a plurality of threaded pins 3 and two blockades 4 .

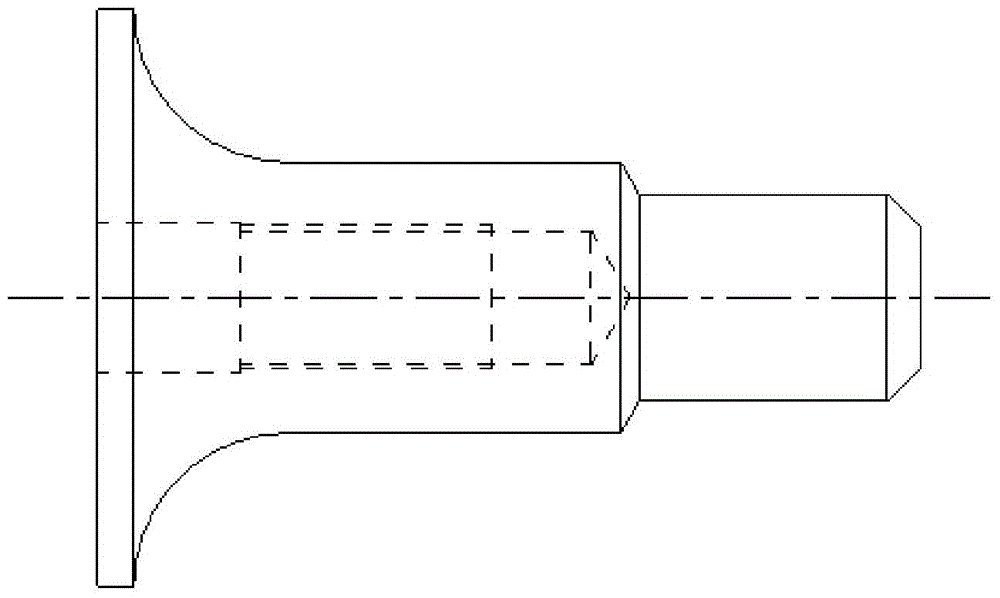

[0024] Such as Figure 4 , Figure 5 As shown, the shape of the end body 1 is the same as that of the cross rod end in the prior art. A blind hole 5 is opened at the large end of the end body 1 , and a plurality of through holes 6 are opened on the side wall of the end body 1 .

[0025] Such as Figure 6 , Figure 7 As shown, the threaded inner sleeve 2 is a cylindrical structure, which is embedded in the blind hole 5 of the end body 1, and the outer wall of the threaded inner sleeve 2 is provided with a plurality of threaded holes 7 corresponding to the through holes 6 along the circumference. The internal thread of the threaded inner sleeve 2 adopts the same SPIRALOC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com