Oil return type double-sided small circular knitting machine

A small circular knitting and double-sided technology, which is applied to circular knitting machines with separate action needles for weft knitting, textile and paper making, weft knitting, etc. problems, to reduce consumption, save costs, and improve the effect of lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

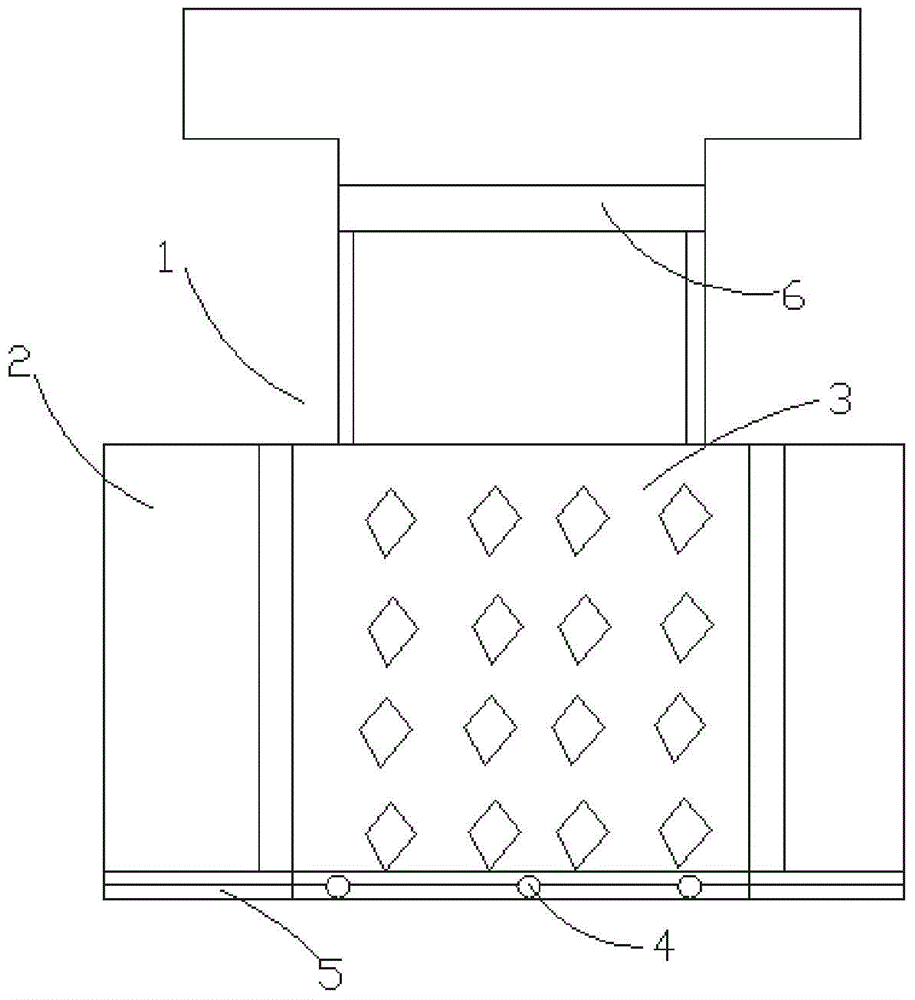

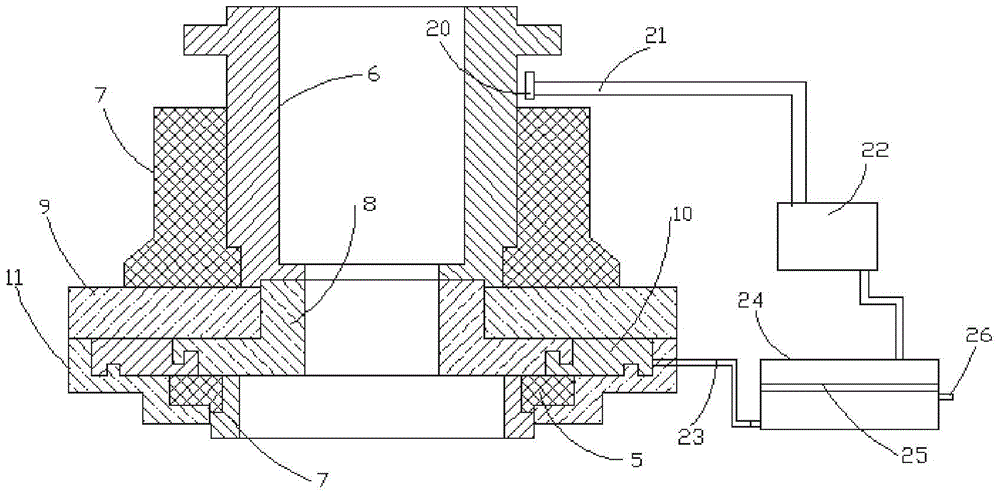

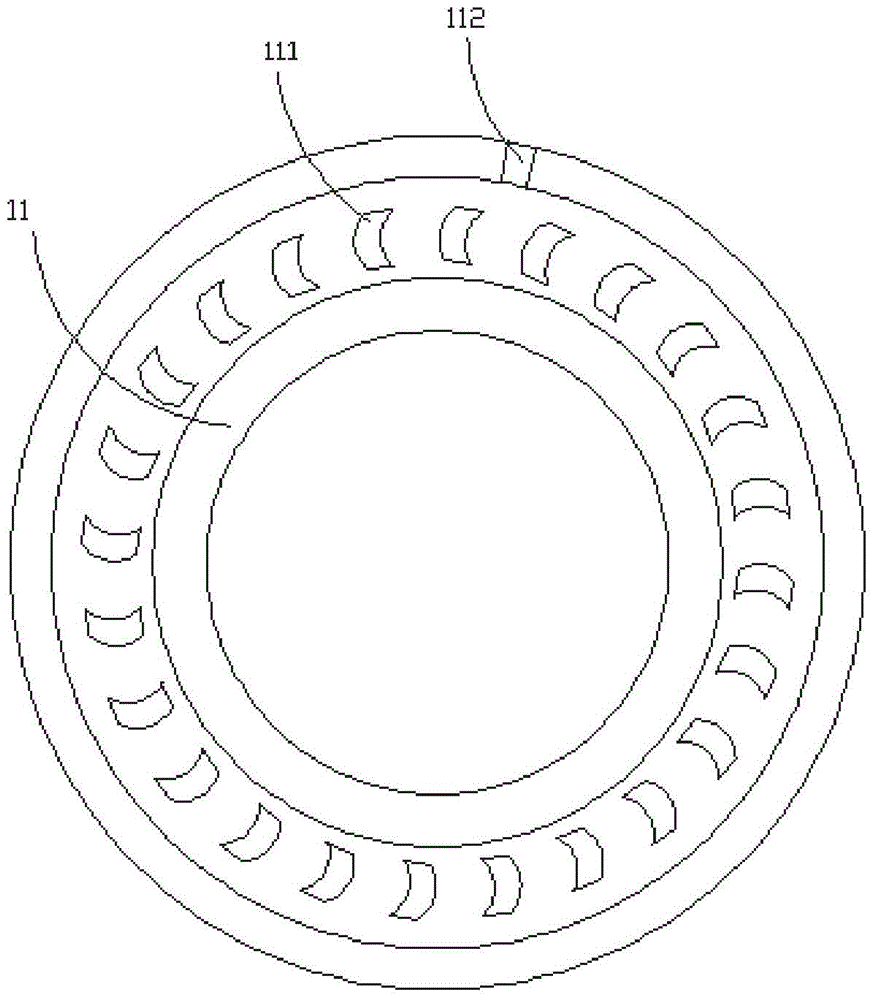

[0017] Such as figure 1 , figure 2 with image 3 As shown, the present invention relates to an oil return type double-sided small circular knitting machine, which is characterized in that it includes a frame 1, and a support column 2 arranged in a triangular distribution is formed at the bottom of the frame 1, and a ventilation belt is provided outside the support column 2. The arc-shaped safety guardrail 3 of the hole, the bottom of the arc-shaped safety guardrail 3 is provided with a pulley 4, and the pulley 4 is slidably arranged in the slide rail 5 installed on the base of the frame 1 to realize the arc-shaped safety guardrail 3 Move left and right; a syringe 6 is provided on the frame 1, a cam seat 7 is socketed on the outer wall of the syringe 6, a syringe seat 8 is installed at the lower end of the syringe 6, and between the syringe seat 8 and the triangular seat 7 A triangular chassis 9 is provided, an anti-oil pressure plate 10 is installed on the lower end surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com