Wire feeder on double-sided small circular knitting machine

A technology of small circular knitting machine and wire feeder, which is applied in the field of wire feeder, which can solve problems such as troublesome wiring, affecting weaving quality, and easy wire breakage, and achieves the effects of reducing winding and knotting, improving weaving quality, and increasing conveying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

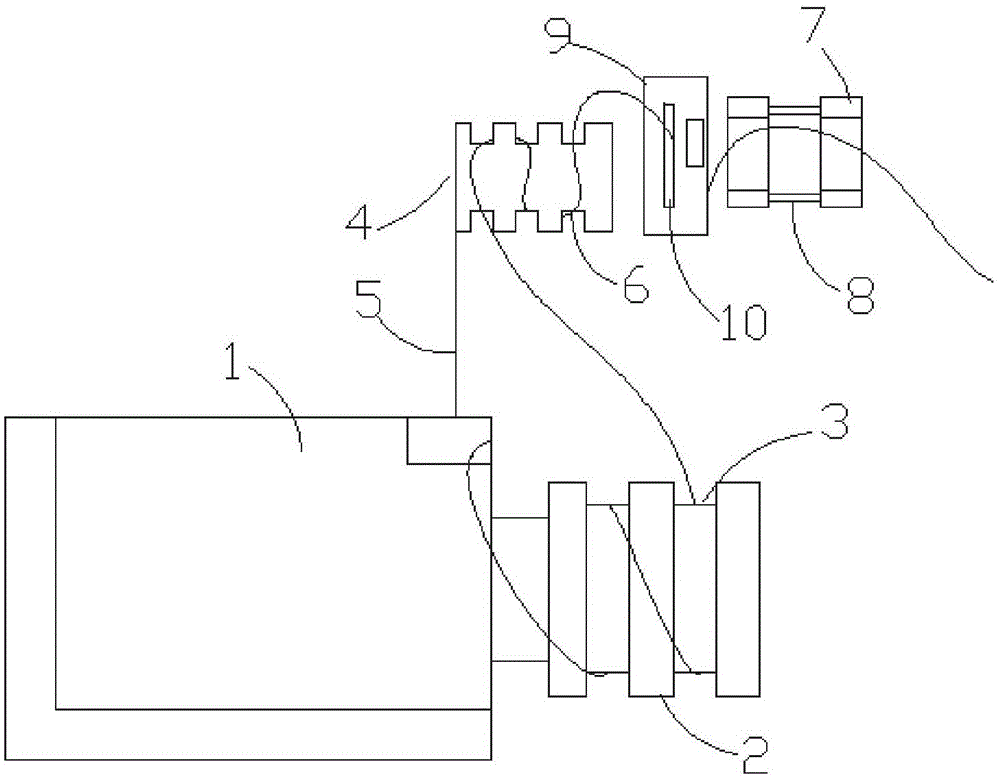

[0012] Such as figure 1 As shown, the present invention relates to a wire feeding device on a double-sided small circular knitting machine, which includes a body 1, and is characterized in that: a wire feeding wheel 2 is arranged on one side of the body 1, and several wires are arranged on the wire feeding wheel 2 Slot 3, the bottom surface of the wire groove 3 is a slope with a large upper part and a smaller lower surface, and a comb wheel 4 is arranged above the wire groove 3, and the comb wheel 4 is arranged on the body 1 by a spring 5; the comb wheel 4 includes more than 2 combing grooves 6, the bottom surface of the combing groove 6 is an inclined plane with a large upper part and a smaller lower part, and also includes 2 balls 7, and a spring member 8 is arranged between the balls 7, between the combing wheel 4 and the A clip 9 is provided between the balls 7, and clip slots 10 with different widths are provided on the clip 9.

[0013] The above is only an embodiment of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com