Coal wall spalling and roof fall control technology in longwall and large mining height working face with large dip angle coal seam

A technology with a large inclination angle of the working face, which is applied in ground mining, mine roof supports, mining equipment, etc., to achieve the effect of improving the number of occurrences of slabs and roof falls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

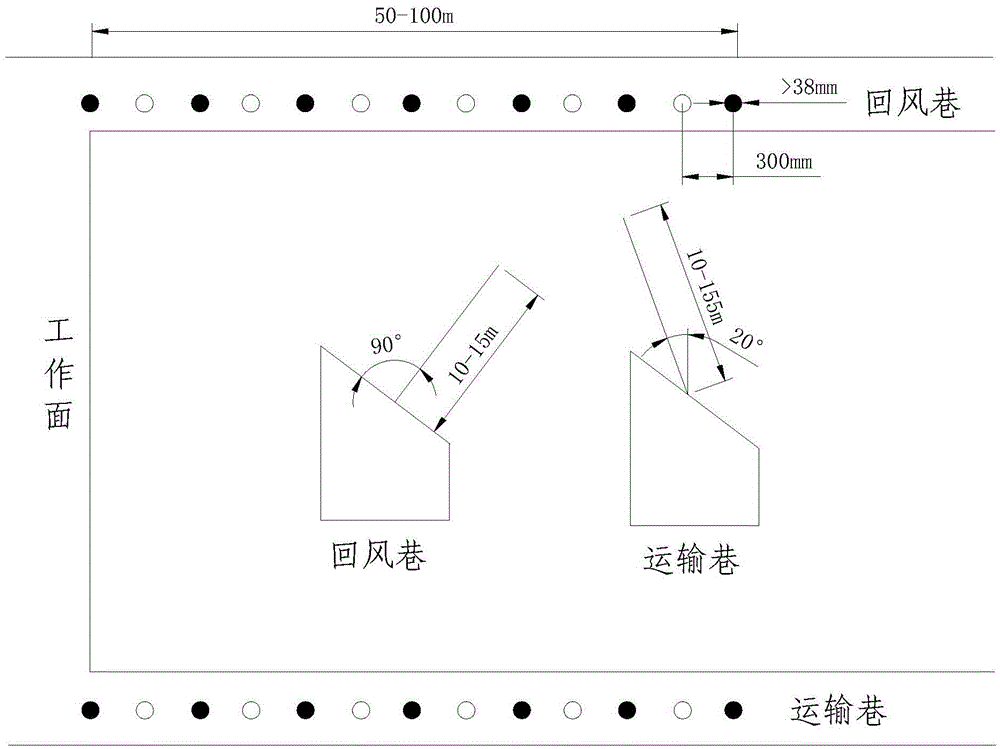

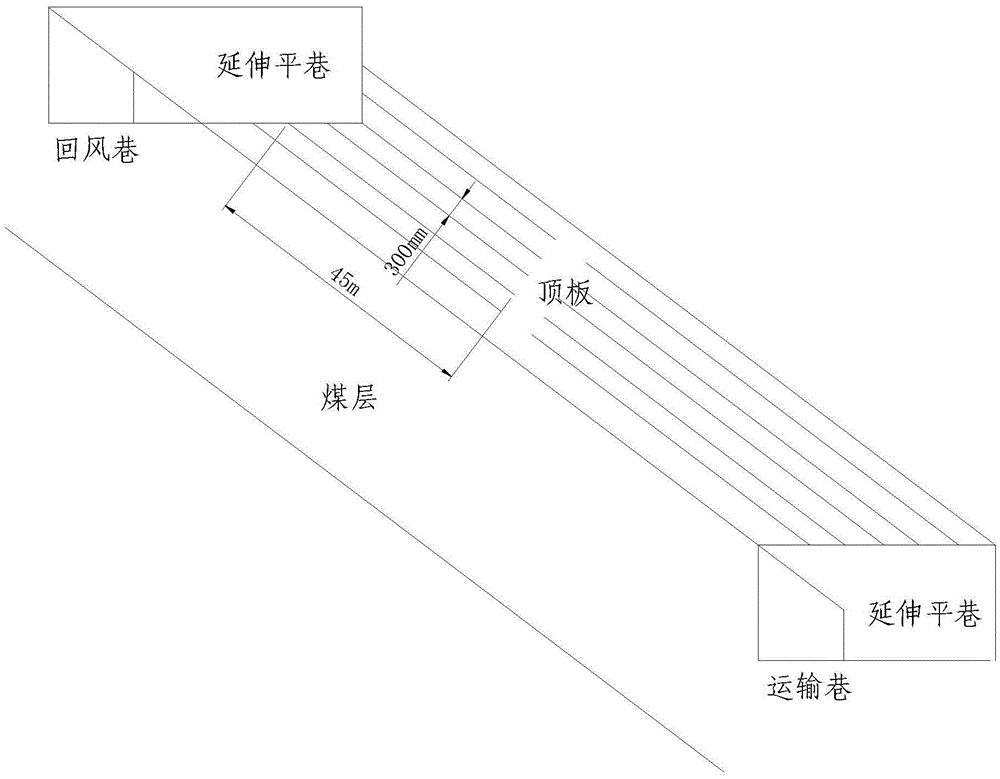

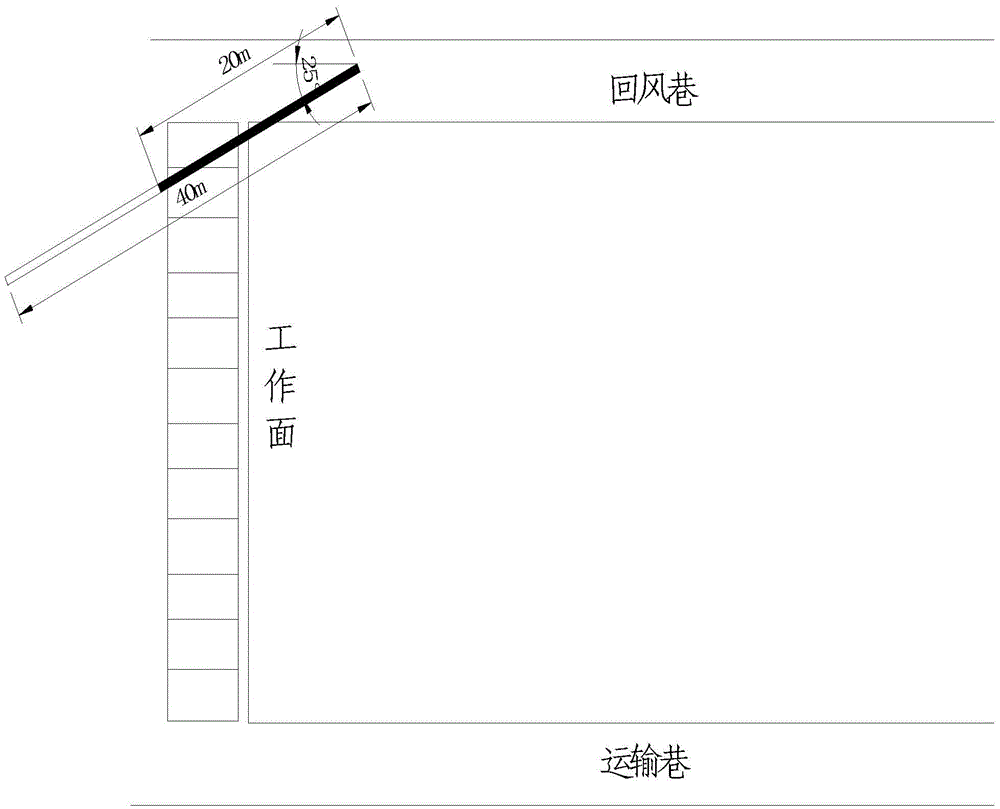

[0024] Coal wall slab and roof fall control technology on the long wall and large mining height working face of large dip angle coal seam Through in-depth analysis of the coal wall slab and roof fall on the large mining height working face of large dip angle coal seam, the following main technical measures need to be taken on site: support work resistance control Technical measures, scientific and reasonable support working resistance and strict support control technology are the key to ensure the stability of the coal wall of the working face:

[0025] (1) Increase the actual initial support force and working resistance of the bracket, increase the hydraulic supply pressure of the pump station as much as possible, and use the initial support force maintenance valve to increase the actual initial support force. In general, the initial support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com