Electronic control high-pressure oil pump, connector reversal detecting device and detecting method

A high-pressure oil pump and detection device technology, which is applied to measurement devices, fuel injection devices, engine testing, etc., can solve the problems of the normal use of the common rail pipe 5', destroying the stability of the oil supply system, and rising rail pressure. The effect of simple structure, simplified structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

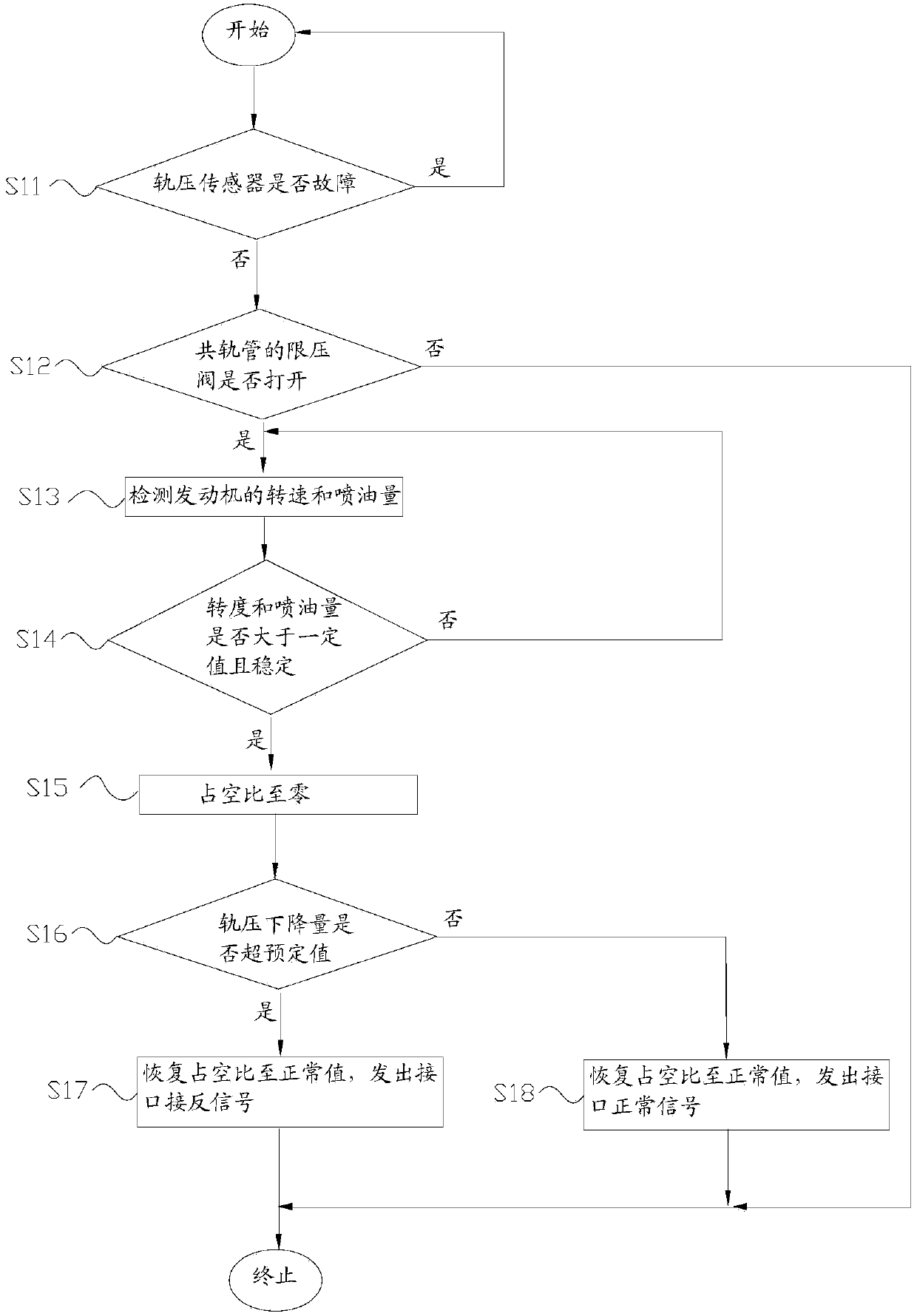

[0045] The core of the present invention is to provide a detection method for the reversed connection of the interface of the electronically controlled high-pressure fuel pump, which can quickly and accurately detect whether the interface is reversed, so as to remind the operator to make changes in time, so that the fuel supply system remains stable.

[0046] Another core of the present invention is to provide a detection device adopting the above detection method to realize the detection of reverse connection of the interface, which has a simple structure, convenient operation and high detection accuracy.

[0047] Another core of the present invention is to provide an electronically controlled high-pressure oil pump including the above detection device, which can detect whether its interface is reversed, so as to adjust the assembly of the interface according to the detection result and avoid damage to the oil pump.

[0048] In order to enable those skilled in the art to bette...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com