A low-leakage high-response high-flow high-speed switching valve

A high-speed on-off valve, high-frequency response technology, applied in fluid pressure actuating devices, servo motor components, mechanical equipment, etc., can solve the problems of small flow capacity, low efficiency of high-speed on-off valves, etc., and achieve the effect of improving control accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

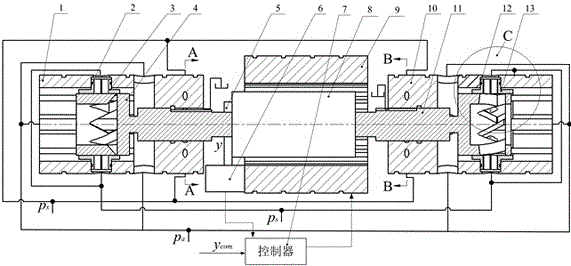

[0024] figure 1 A schematic diagram of the overall structure of the present invention is shown. Including the first valve sleeve 1, the sealing ring 2, the floating compensation block 3, the first valve core 4, the moving part of the displacement sensor 5, the fixed part of the displacement sensor 6, the controller 7, the secondary of the linear motor 8, the primary of the linear motor 9, the first Two valve sleeves 10, a second valve core 11, a sealing ring 12, and a floating compensation block 13.

[0025] The existing high-speed on-off valve control usually adopts PWM control, which is limited by the response frequency and life of the existing high-speed on-off valve itself. The steady-state accuracy is closely related to the PWM control frequency, and as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com