An energy absorbing device using material limit characteristics and its manufacturing method

An energy absorbing device and characteristic technology, applied in elastic shock absorbers and other directions, can solve the problems of poor predictability, excessive load fluctuation and high cost, and achieve the effects of stable failure mode, good load stability and high space utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

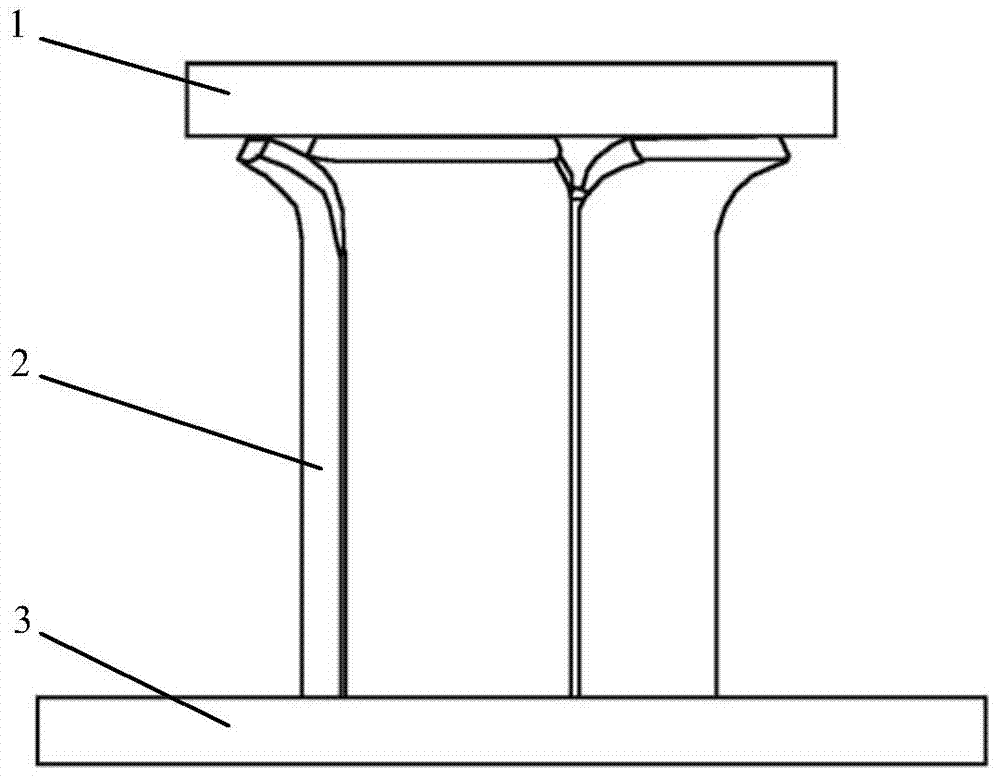

[0037] A specific embodiment of the present invention is provided below, in which the selection of materials and dimensions is not limiting, and those skilled in the art can fully design this energy absorbing device according to the actual situation.

[0038] 1) Materials:

[0039] Energy-absorbing tube--304L yield strength 205MPa tensile strength 520MPa;

[0040] T-shaped head and bottom plate - 42CrMoA yield strength 780MPa tensile strength 980MPa.

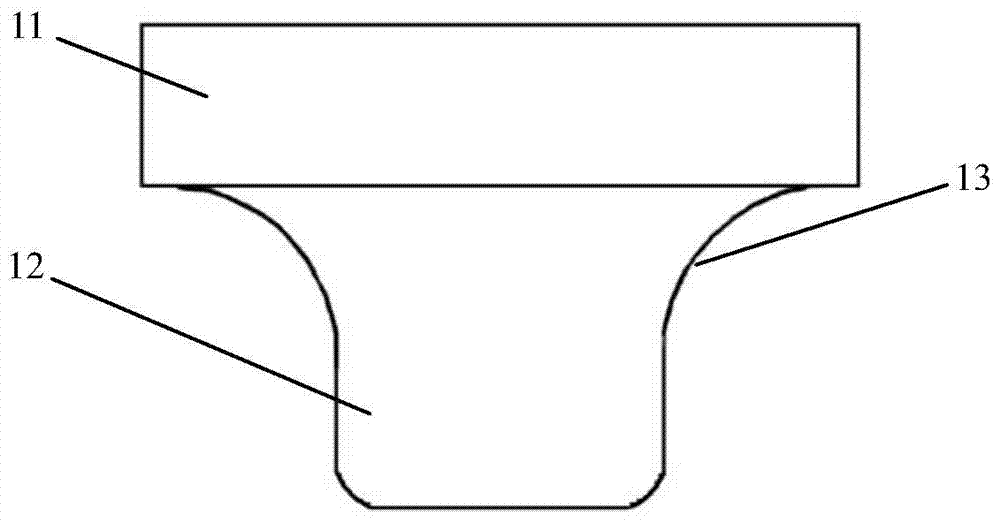

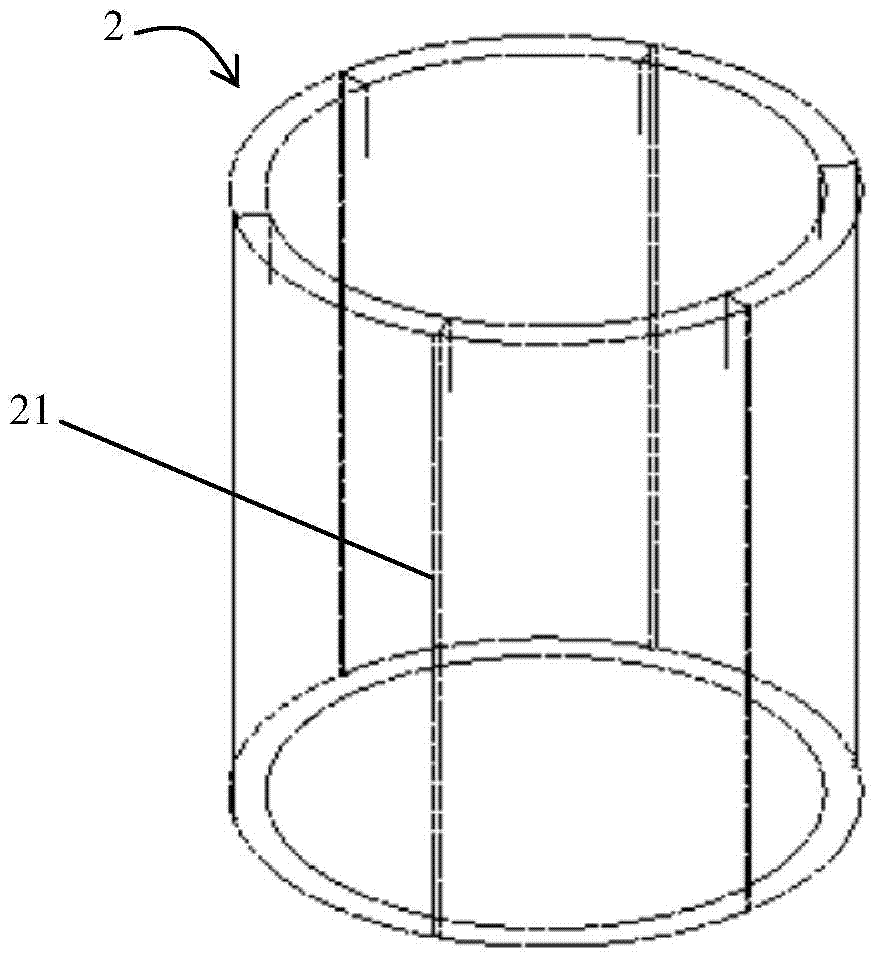

[0041] 2) Structure:

[0042] The outer diameter of the energy-absorbing tube is 219mm, the wall thickness is 12mm, and the height is 356mm;

[0043] The number of preset slots for the energy-absorbing tube is 6, and the preset cracking length is 50mm;

[0044] The chamfering radius of the T-shaped head is 50mm, and the pre-pressed energy-absorbing tube is 80mm.

[0045] 3) Performance:

[0046] The effective energy-absorbing displacement of the energy-absorbing structure is 145mm;

[0047] The impact load of the energy-abso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com