A variable frequency vertical cyclic loading device that can apply complex load forms

A cyclic loading and vertical technology, applied in the direction of applying repetitive force/pulsation force to test the strength of materials, can solve the problems of limited number of test loads, high cost, small load amplitude, etc., to achieve good economy and reliability. Easy maintenance, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

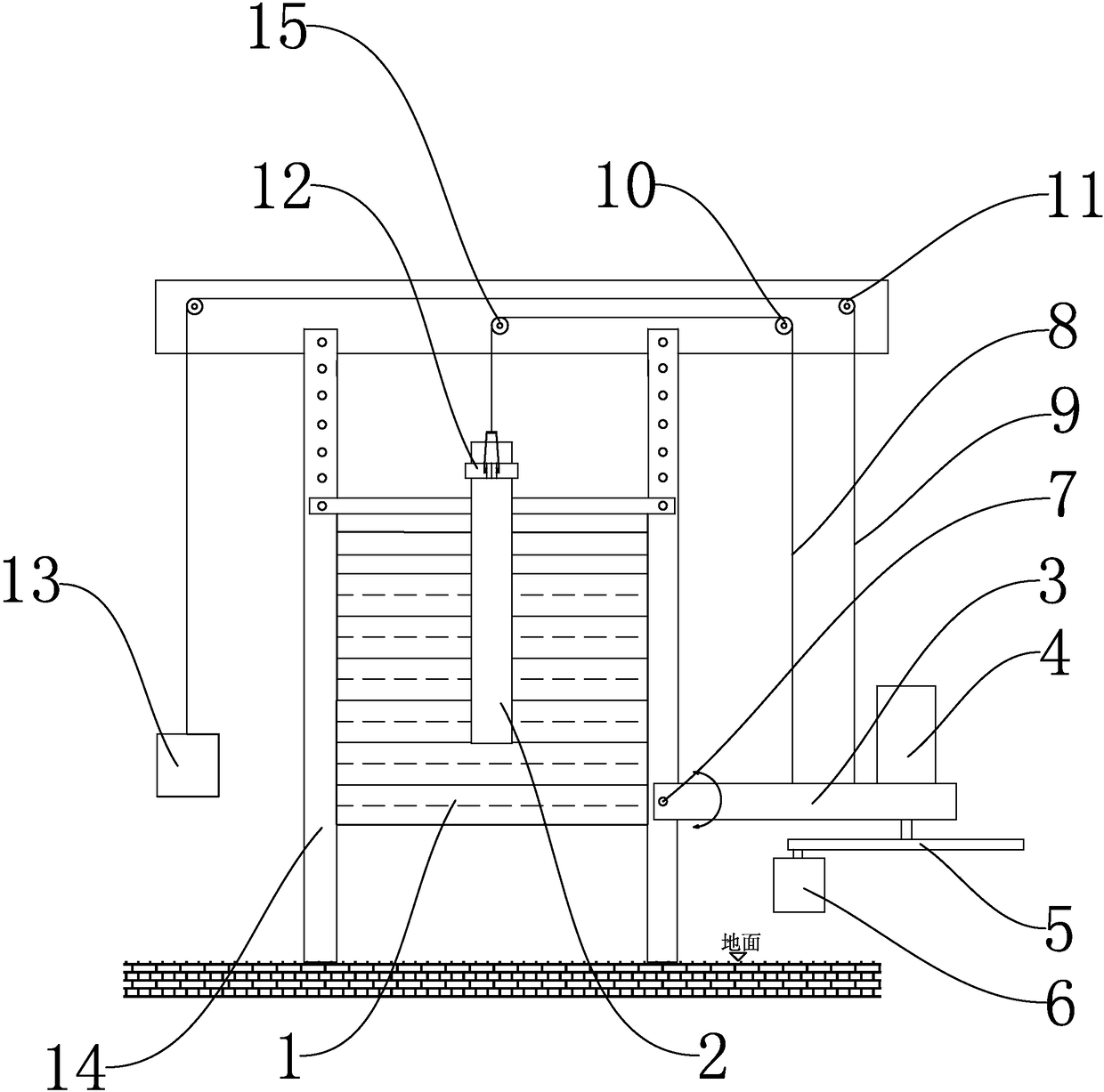

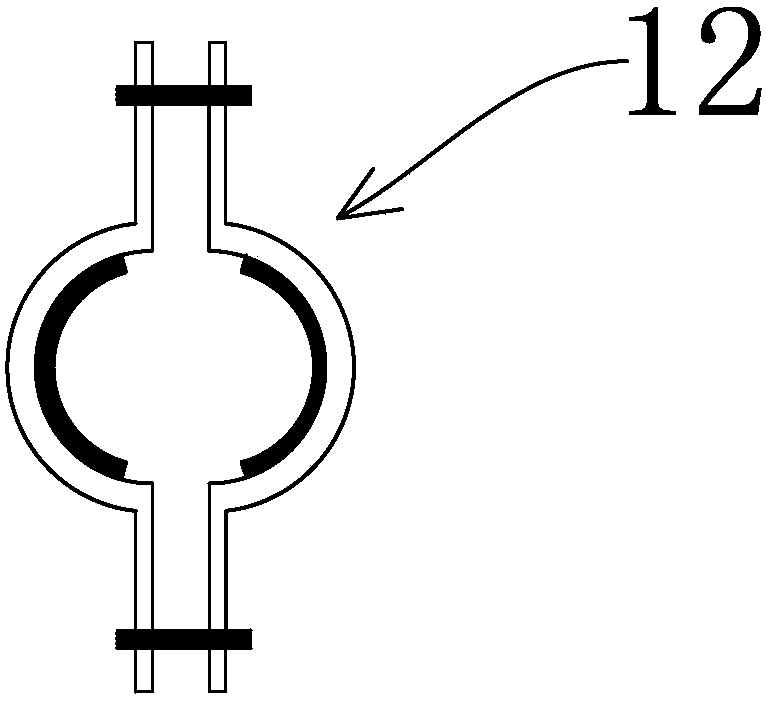

[0014] Such as figure 1 As shown, the present embodiment is a variable-frequency vertical cyclic loading device capable of applying complex loads. It has a model box 1 and a model pile 2 vertically fixed in the model box. The upper end of the model pile 2 is connected to apply a vertical load to it. Loaded moment loading mechanism.

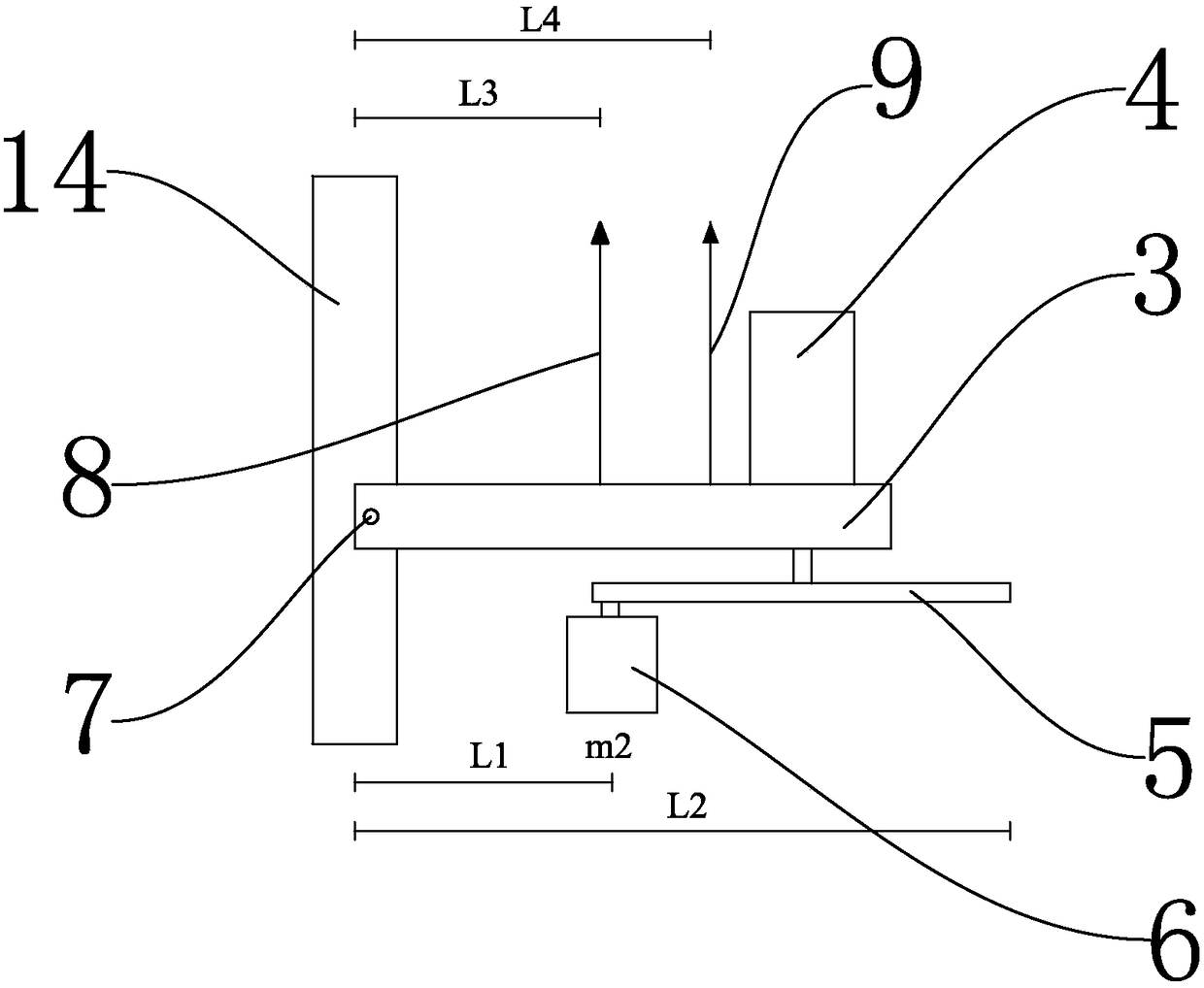

[0015] Such as figure 2 As shown, the moment loading mechanism in this example has a center of gravity changing mechanism and a counterweight I13, and the center of gravity changing mechanism includes a connecting platform 3, a motor 4, a turntable 5 and a counterweight II6, wherein the connecting platform 3 is fixed on the ground via a steel bracket 14, Between the connecting platform 3 and the steel support 14, the horizontally arranged rotating shaft 7 realizes rotation and connection. The other end of the connecting platform 3 is equipped with a motor 4. The rotating shaft of the motor is vertically connected to the platform 3. The rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com