Ionitriding equipment fault diagnosis system

A technology of ion nitriding and equipment failure, applied in the direction of measuring devices, instruments, measuring electricity, etc., can solve problems such as failure of ion nitriding equipment to be found in time, to avoid failure to be found in time, high accuracy and efficiency, and easy follow-up maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

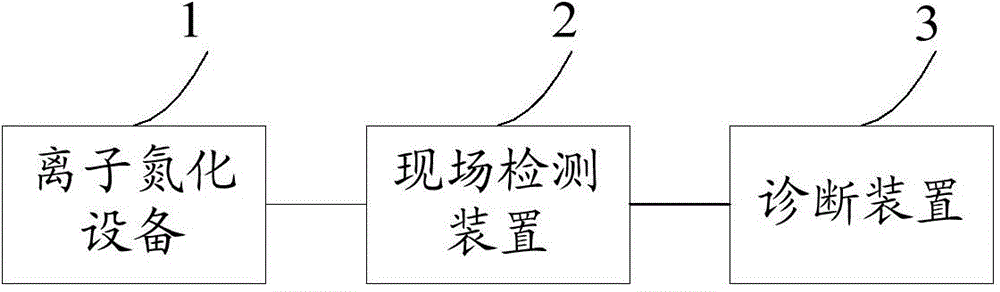

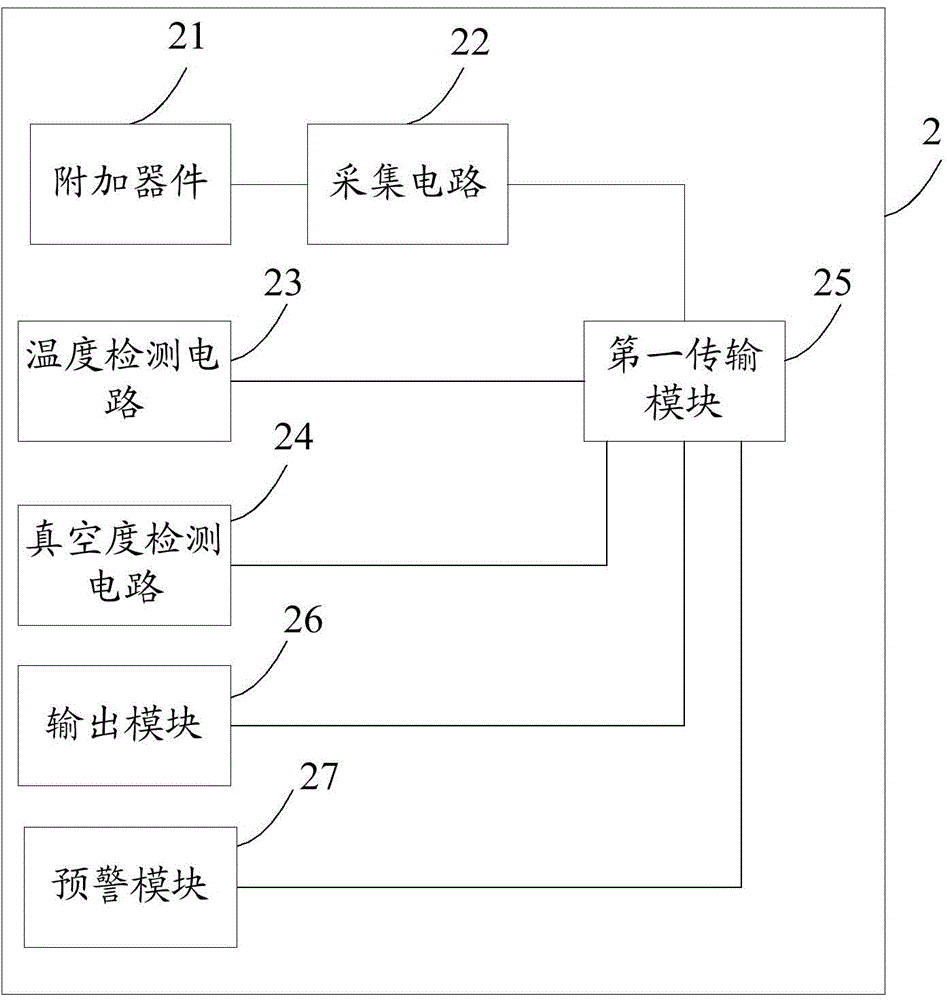

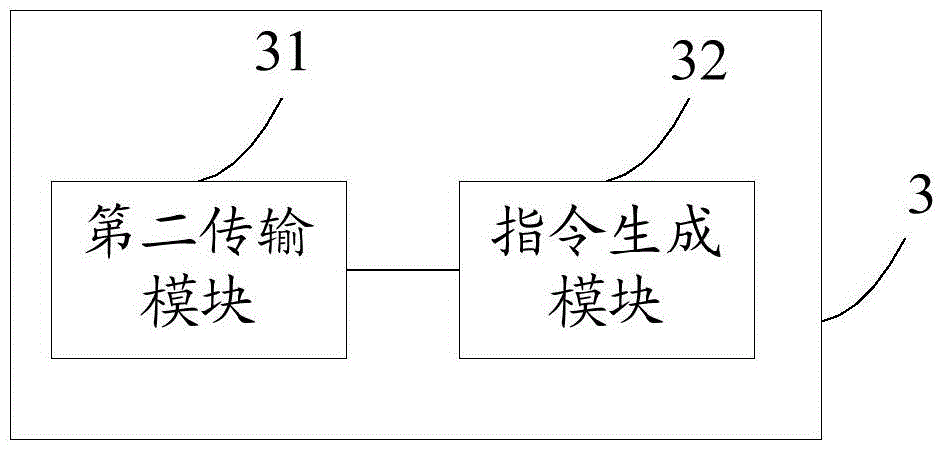

[0040] An embodiment of the present invention provides a fault diagnosis system for ion nitriding equipment, see Figure 1 ~ Figure 3 , the system consists of:

[0041] An on-site detection device 2 connected to the ion nitriding equipment 1, a diagnostic device 3 connected to the on-site detection device 2;

[0042] The on-site detection device 2 is used to obtain the parameters of the nodes of the ion nitriding equipment, and the nodes of the ion nitriding equipment include the power system of the ion nitriding equipment, the circuit in the action control board and the vacuum system, and the furnace body of the ion nitriding equipment And cathode and anode, the parameters of the node include the current value of the node, the voltage value of the node, the switch data of the node, the temperature of the node, the vacuum degree of the node, and the switch data includes on and off;

[0043] The diagnosis device 3 is used to judge whether the ion nitriding equipment fails acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com