Full-automatic security pilot burner for combustor

A fully automatic, permanent light technology, applied in burners, gas fuel burners, combustion methods, etc., can solve the problems of gas leakage, heating furnace deflagration, rapid gas diffusion, etc., to avoid leakage and improve safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

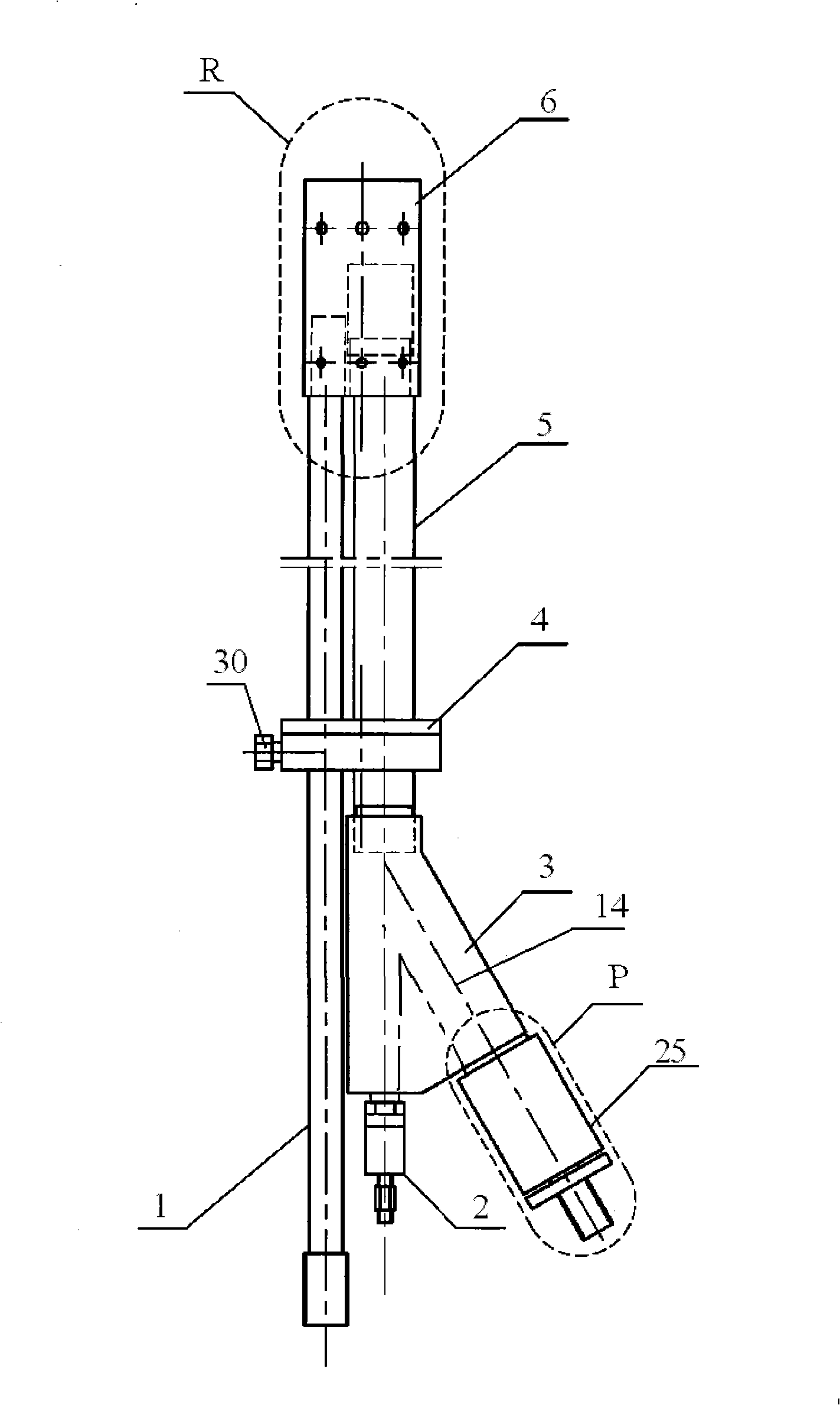

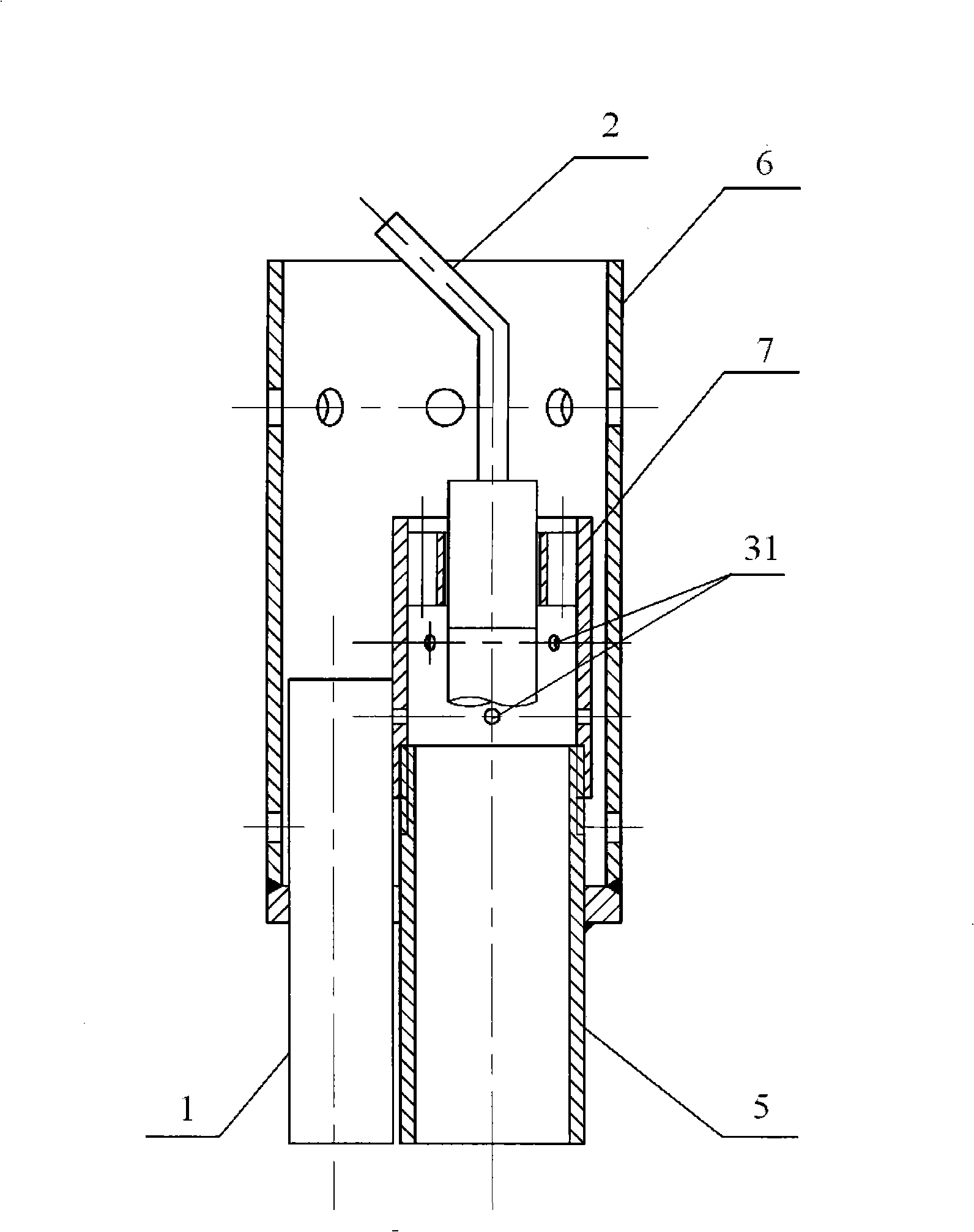

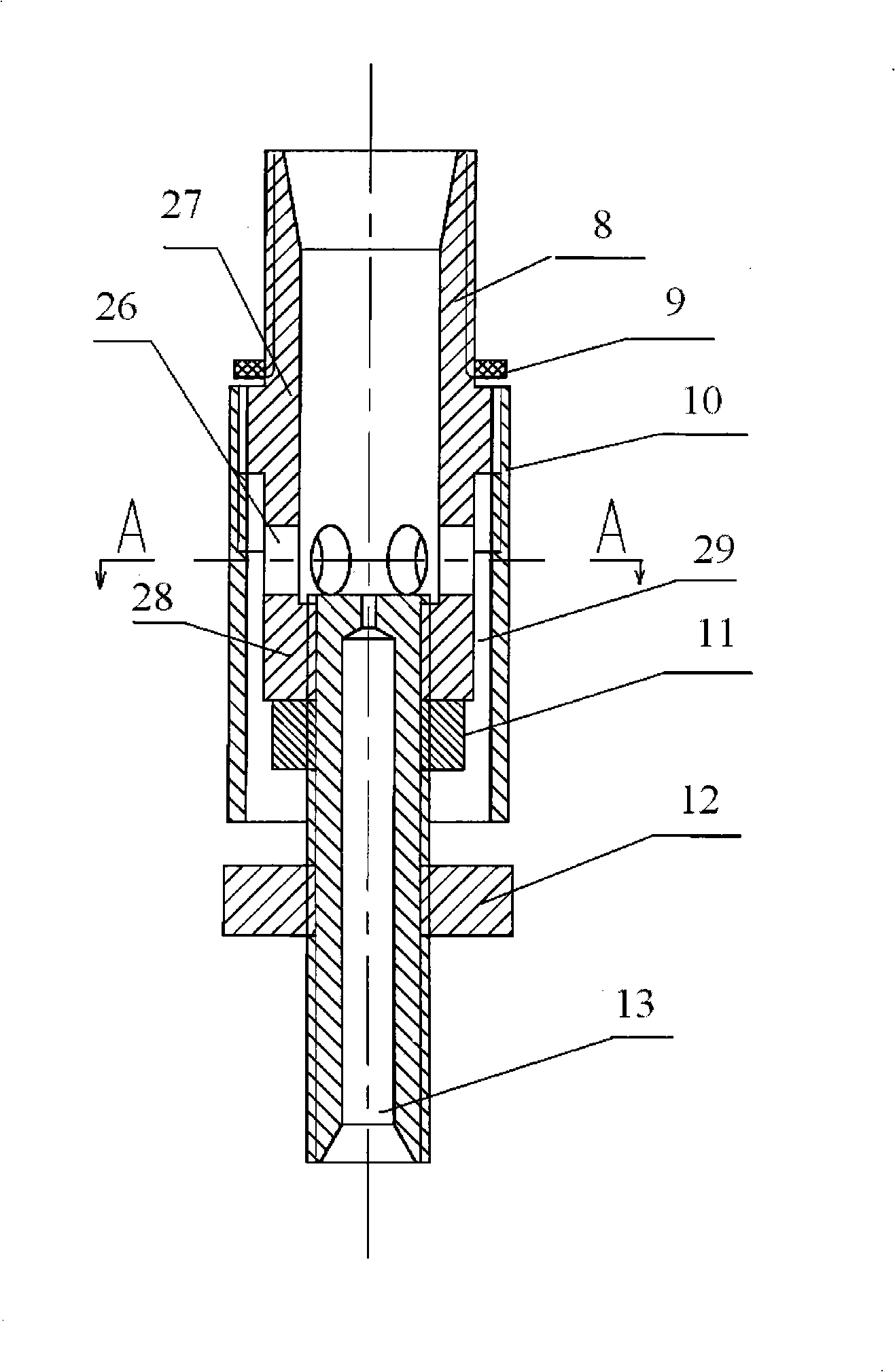

[0016] Such as figure 1 with figure 2 As shown, a full-automatic safety lamp for a burner includes an ignition electrode 1 connected to an ignition device and a riser tube 5 . The ignition electrode 1 and the rising pipe 5 are arranged side by side through the flange 4 , and the flange 4 is provided with fixing screws 30 for fixing the ignition electrode 1 . A flame-stabilizing tube 6 is welded on the outside of the upper end of the ignition electrode 1 and the riser tube 5. The lower end of the riser tube 5 is provided with a tee connection block 3, and the ionization fire detection electrode 2 is installed along the riser tube 5. Gas burner 7, the upper end of gas burner 7 is higher than the upper end of ignition electrode 1, and the upper end of gas burner 7 is higher than the upper end of ignition electrode 1, which ensures that ignition electrode 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com