Waveguide Integrated Imaging 3D Display System Based on Diffractive Optical Elements

A diffractive optical element and three-dimensional display technology, applied in optical elements, optical waveguide light guides, optics, etc., can solve the problems of heavy weight, large volume, complex structure, etc., and achieve the effect of high transmittance and large system pupil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

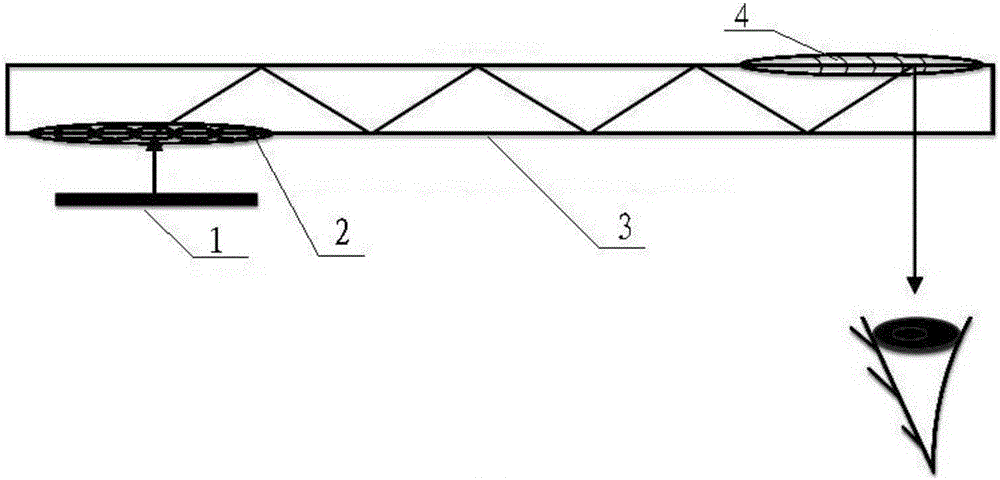

[0045] In embodiment 3, such as Figure 4 As shown, the input diffractive optical element 2 is a combination of a transmission holographic microlens array and a transmission holographic lens, located on the lower surface of the input end of the slab waveguide, and the output diffractive optical element 4 is a reflective holographic lens, located on the lower surface of the slab waveguide the top surface of the output. The combination of the transmissive holographic microlens array and the transmissive holographic lens has the functions of the holographic microlens array and the holographic lens.

Embodiment 4

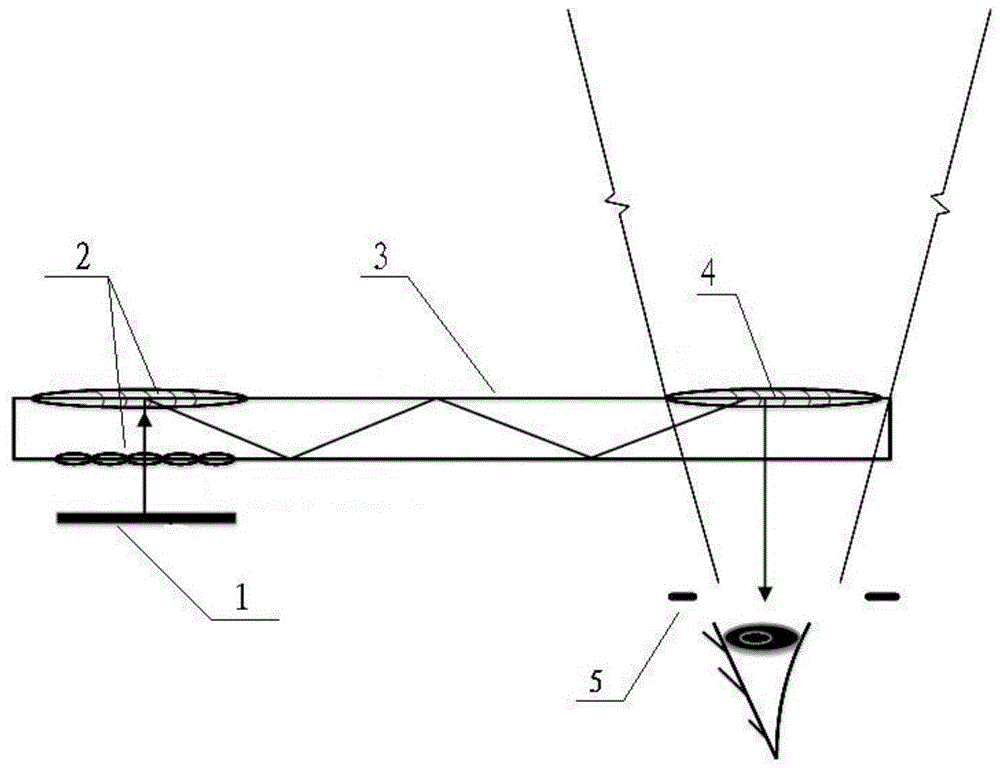

[0046] In embodiment 4, such as Figure 5 As shown, the input diffractive optical element 2 is a combination of a transmission holographic microlens array and a transmission holographic lens, located on the lower surface of the input end of the slab waveguide, and the output diffractive optical element 4 is a transmission holographic lens, located on the lower surface of the slab waveguide the lower surface of the output. The combination of the transmissive holographic microlens array and the transmissive holographic lens has the functions of the holographic microlens array and the holographic lens.

Embodiment 5

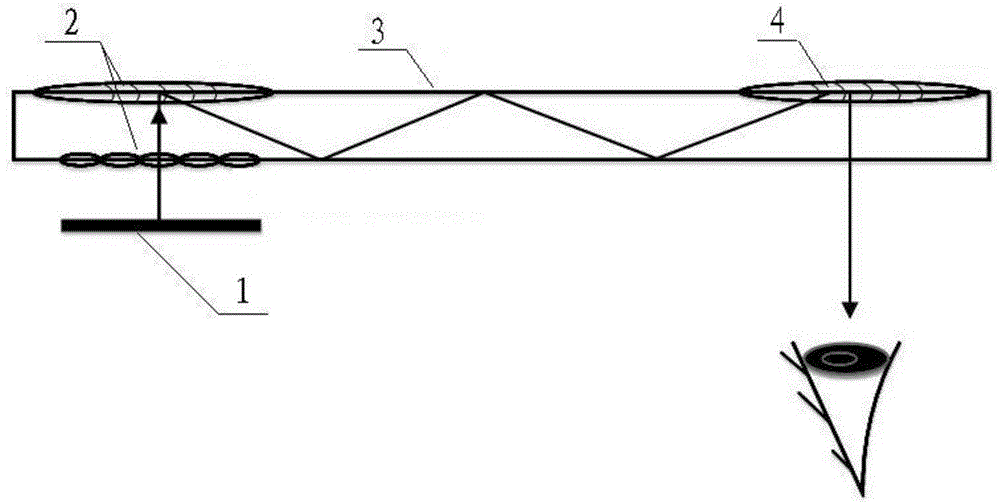

[0047] In embodiment 5, such as Figure 6 As shown, the input diffractive optical element 2 is a combination of reflective holographic microlens array and reflective holographic lens, located on the upper surface of the input end of the slab waveguide, and the output diffractive optical element 4 is a reflective holographic lens, located on the slab waveguide the top surface of the output. The combination of the reflective holographic microlens array and the reflective holographic lens has the functions of the holographic microlens array and the holographic lens.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com