A Tool Clamping Device for Complicated Curved Surface Conformal Machining

A technology of clamping device and complex curved surface, which can be used in positioning devices, manufacturing tools, metal processing equipment, etc., and can solve the problems of uncertain workpiece accuracy and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

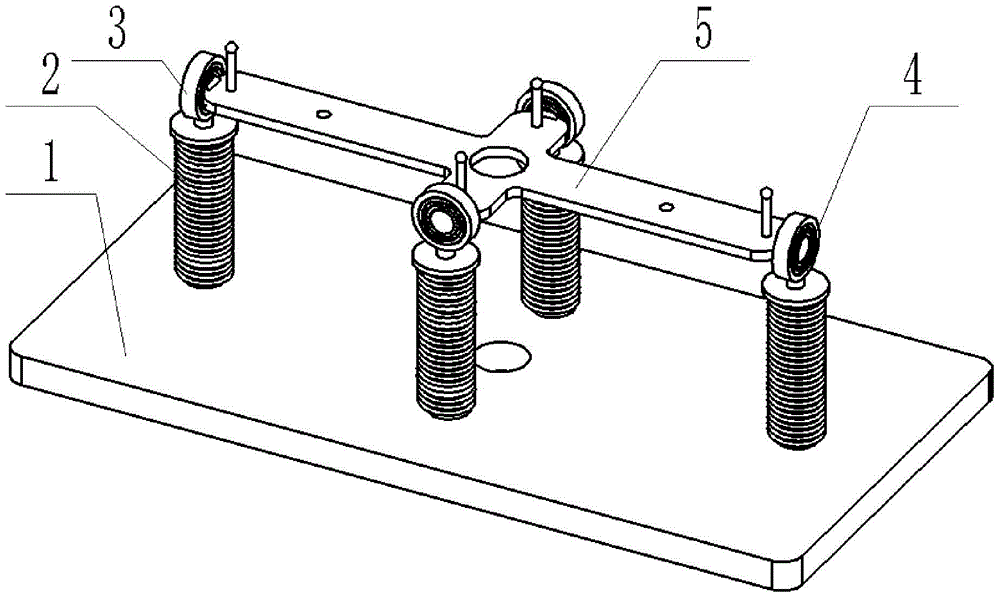

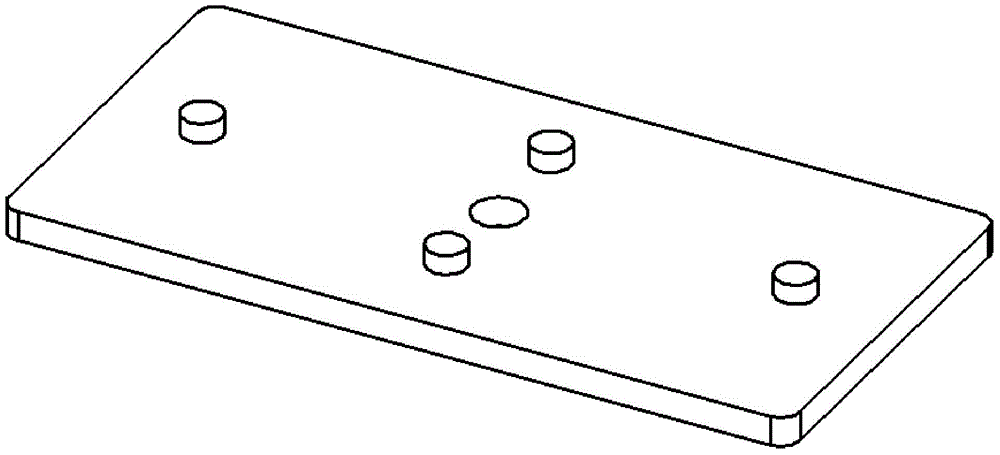

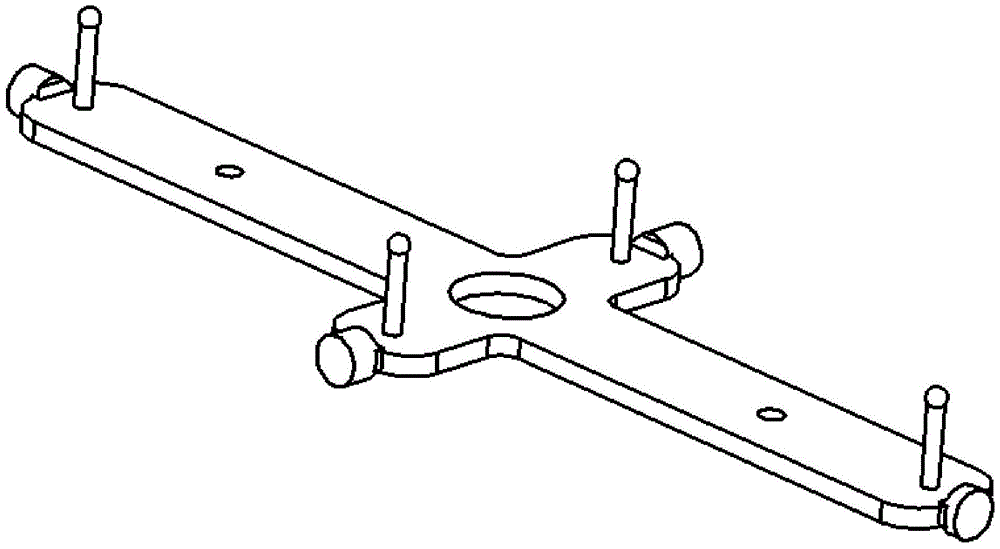

[0010] A tool clamping device for conformal machining of complex curved surfaces, comprising a main shaft mounting plate 1, a conformal spring 2, lugs 3, bearings 4, and a conformal plate 5, the main shaft mounting plate 1 has a main shaft mounting hole and Contour spring positioning block, Contour plate 5 is provided with Contour pad rail and tool installation hole, Contour spring 2 is respectively fixed on the Contour spring positioning block of spindle mounting plate 1, Hanging lug 3 is respectively fixed on Contour spring 2 Above, the conformal plate 5 is connected with the lug 3 through the bearing 4 .

[0011] When using this device, install the spindle on the spindle mounting hole of the spindle mounting plate 1, install the end milling tool on the tool mounting hole of the conformal plate 5, and pass the spindle and the end milling tool through the universal joint Connection, when using the device to clamp the tool for conformal machining, press the side with the tool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com