Bottom-suspension equipment mounting structure and chassis of railway vehicle

A technology for rail vehicles and installation structures, applied in the direction of chassis, transportation and packaging, railway car body parts, etc., can solve the problems of reduced passenger comfort, increased vibration, vibration and impact, etc., to improve comfort and improve installation reliability. The effect of resistance and deformation prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

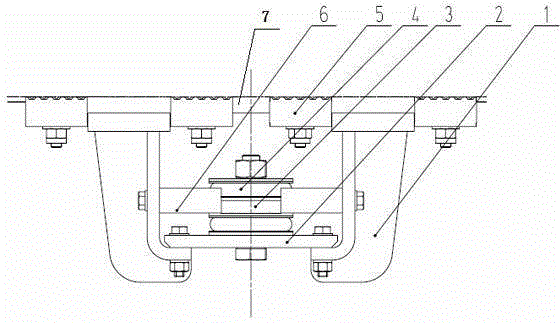

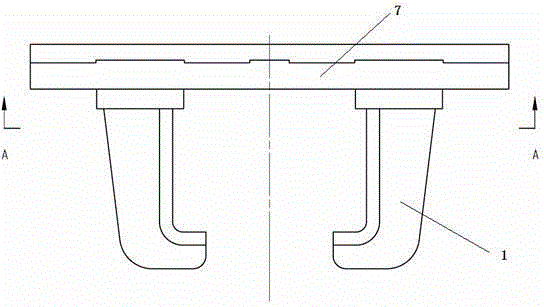

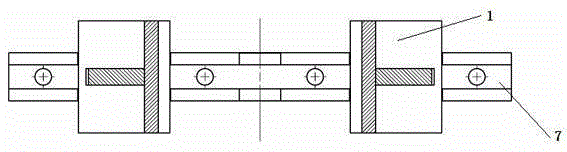

[0019] Such as figure 1 Shown, a kind of installation structure of the equipment under the rail vehicle has a suspension seat, and the suspension seat includes two suspension plates 1 installed relatively vertically, and a slide block 7 installed on the top of the suspension plate 1, as shown in FIG. figure 2 As shown, each suspension plate 1 includes a vertical plate and a horizontal plate bent toward the other suspension plate at the bottom of the vertical plate, and the support plate 2 is installed on the top surface of the horizontal plate of the two suspension seats, and the equipment 3 is installed on the support plate 2 top surface; the installation structure also includes a device vibration damping mechanism and a stopper 6 that limits the horizontal movement of the device. Two stoppers 6 are installed on each suspension plate 1, and four stoppers 6 are installed symmetrically. The vibration-damping mechanism includes vibration-damping pads 4 respectively arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com