Multi-angle precise adjusting mechanism for fan blades

A precision adjustment, angle adjustment technology, applied in mechanical equipment, machine/engine, liquid fuel engine, etc., can solve the problems of limited angle adjustment range, unsatisfactory positioning effect, unreasonable design, etc., to achieve wide angle adjustment range, noise Small, well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

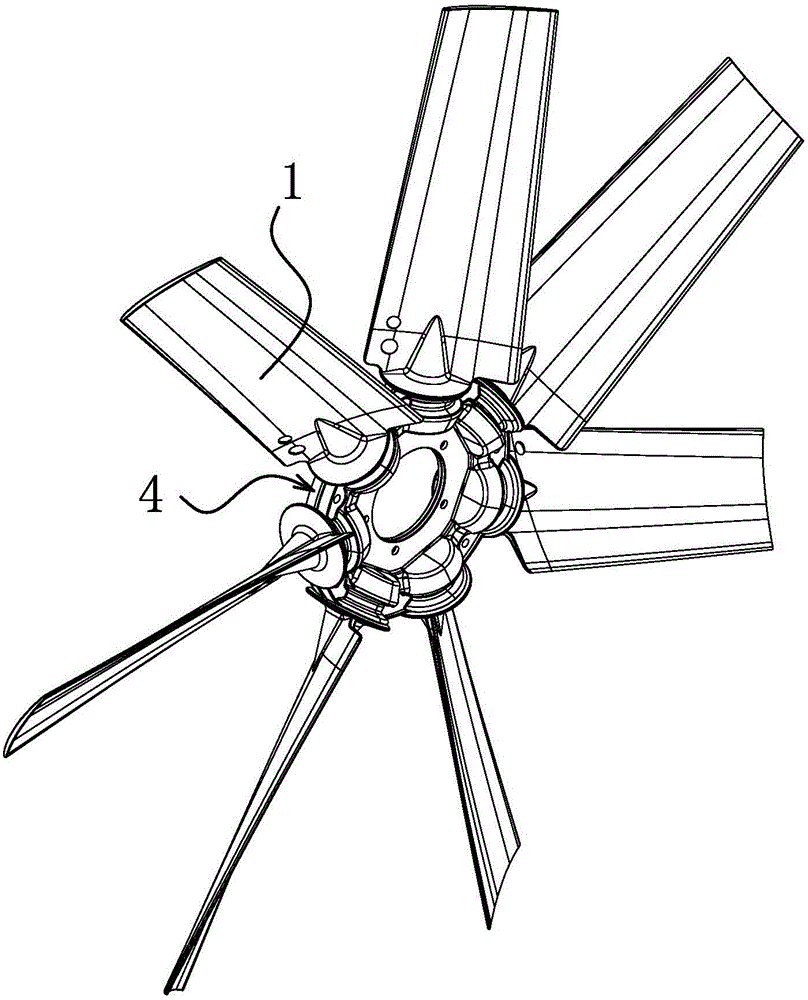

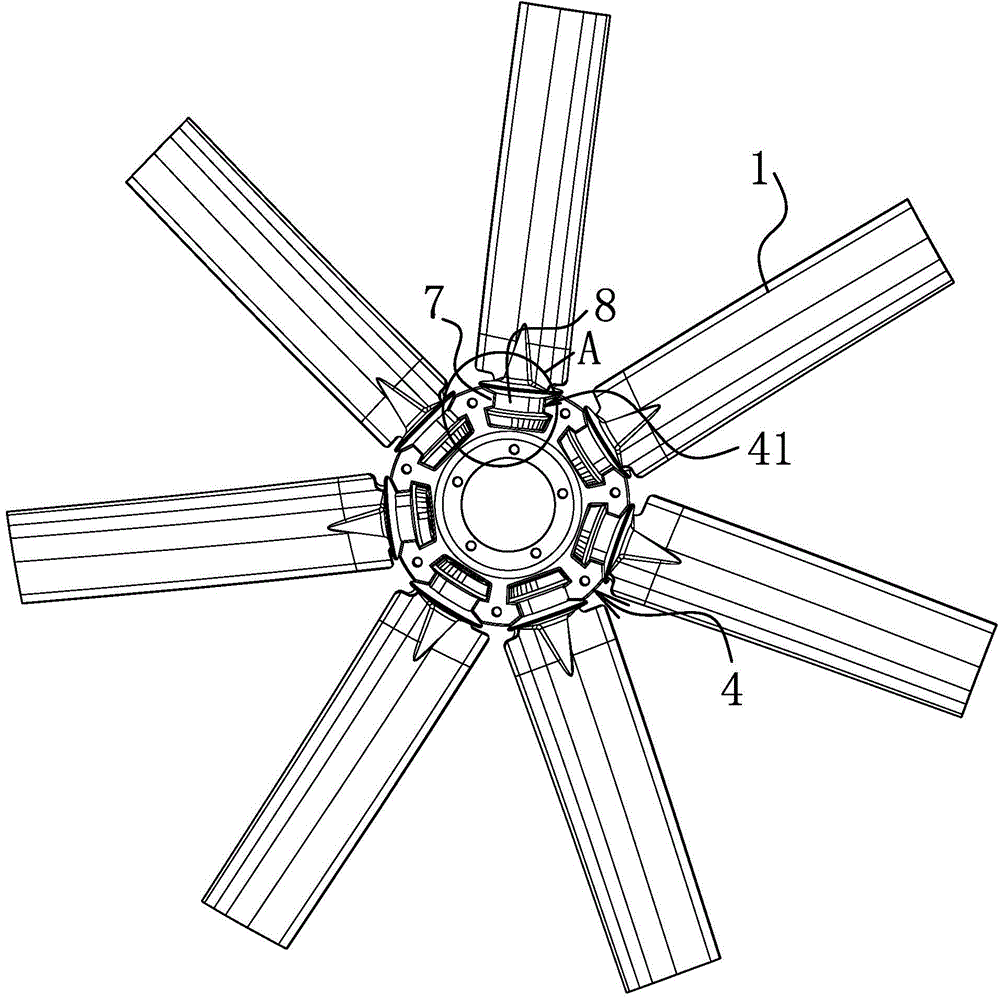

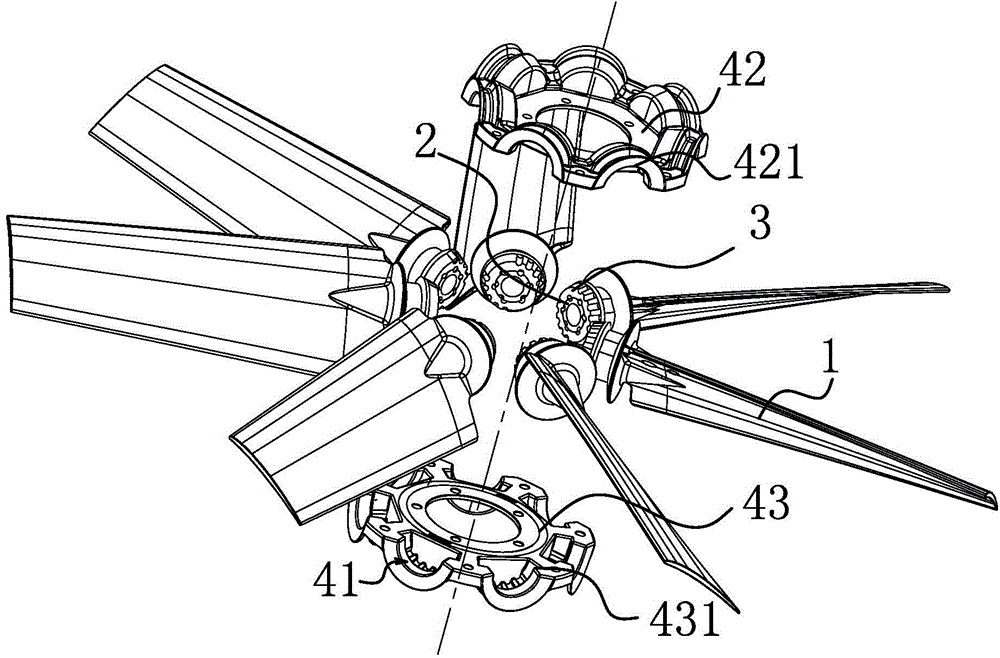

[0025] Such as Figure 1-6 As shown, the fan blade multi-angle precision adjustment mechanism, this mechanism includes a connecting head 2 arranged at the root of the fan blade 1, an adjusting positioning sleeve 3 is set on the periphery of the connecting head 2, and the adjusting positioning sleeve 3 is inserted into the side of the mounting plate 4 In the connection hole 41, a first angle adjustment positioning structure 5 is provided between the outside of the adjustment positioning sleeve 3 and the connection hole 41, and a second angle adjustment positioning structure 6 is provided between the inside of the adjustment positioning sleeve 3 and the connector 2.

[0026] The first angle adjustment positioning structure 5 includes several disc grooves 51 arranged in the connection hole 41 and distributed along the circumference of the connection hole 41 and several grooves 51 arranged outside the adjustment positioning sleeve 3 and distributed along the circumference of the ad...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap