Assembly and method for transferring rod-shaped items for the tobacco processing industry from a sender unit to a receiver unit

A technology of a sending unit and a receiving unit, which is applied in the field of device of rod-shaped products, can solve the problems of energy consumption and unfavorable product protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

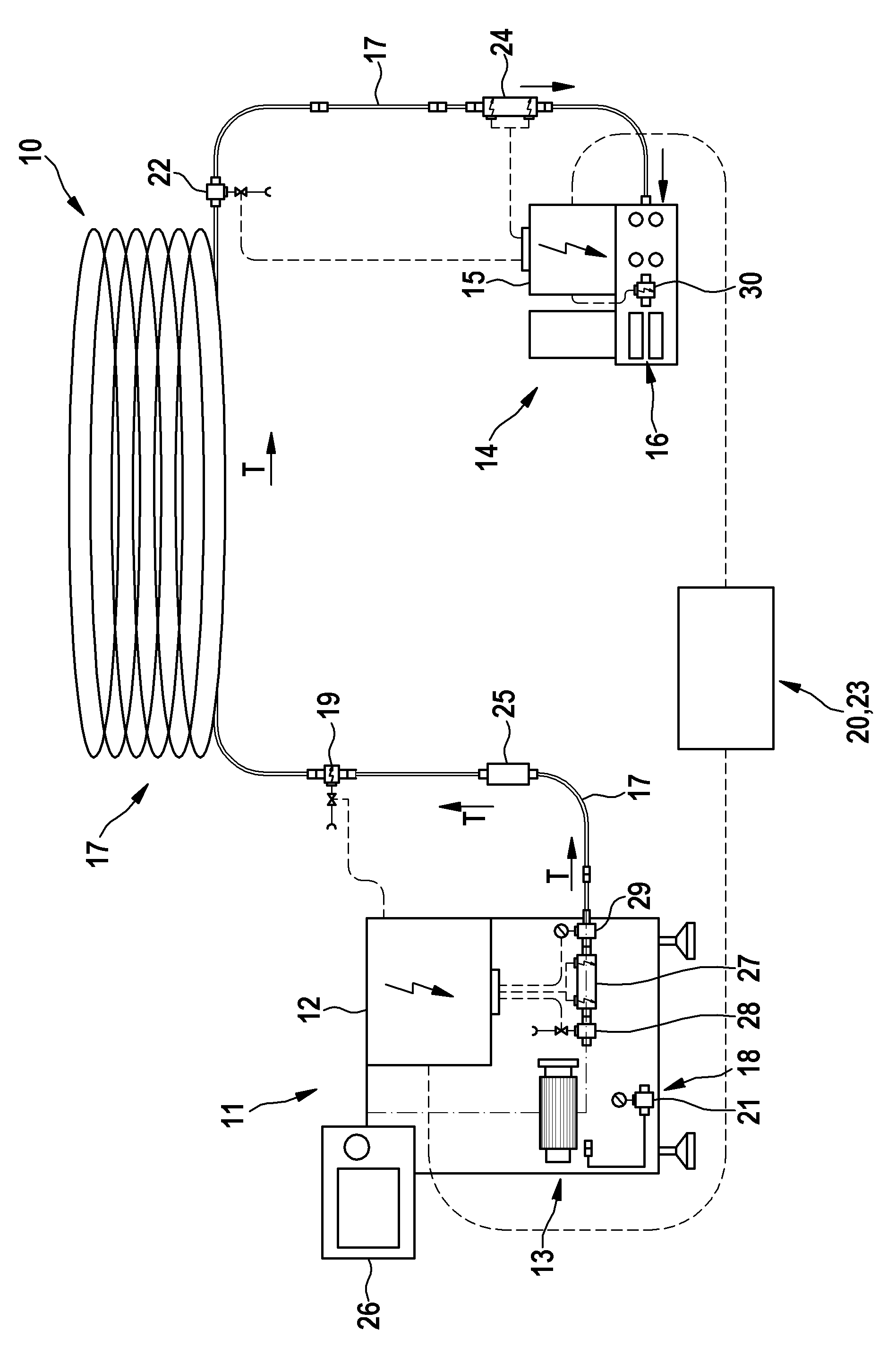

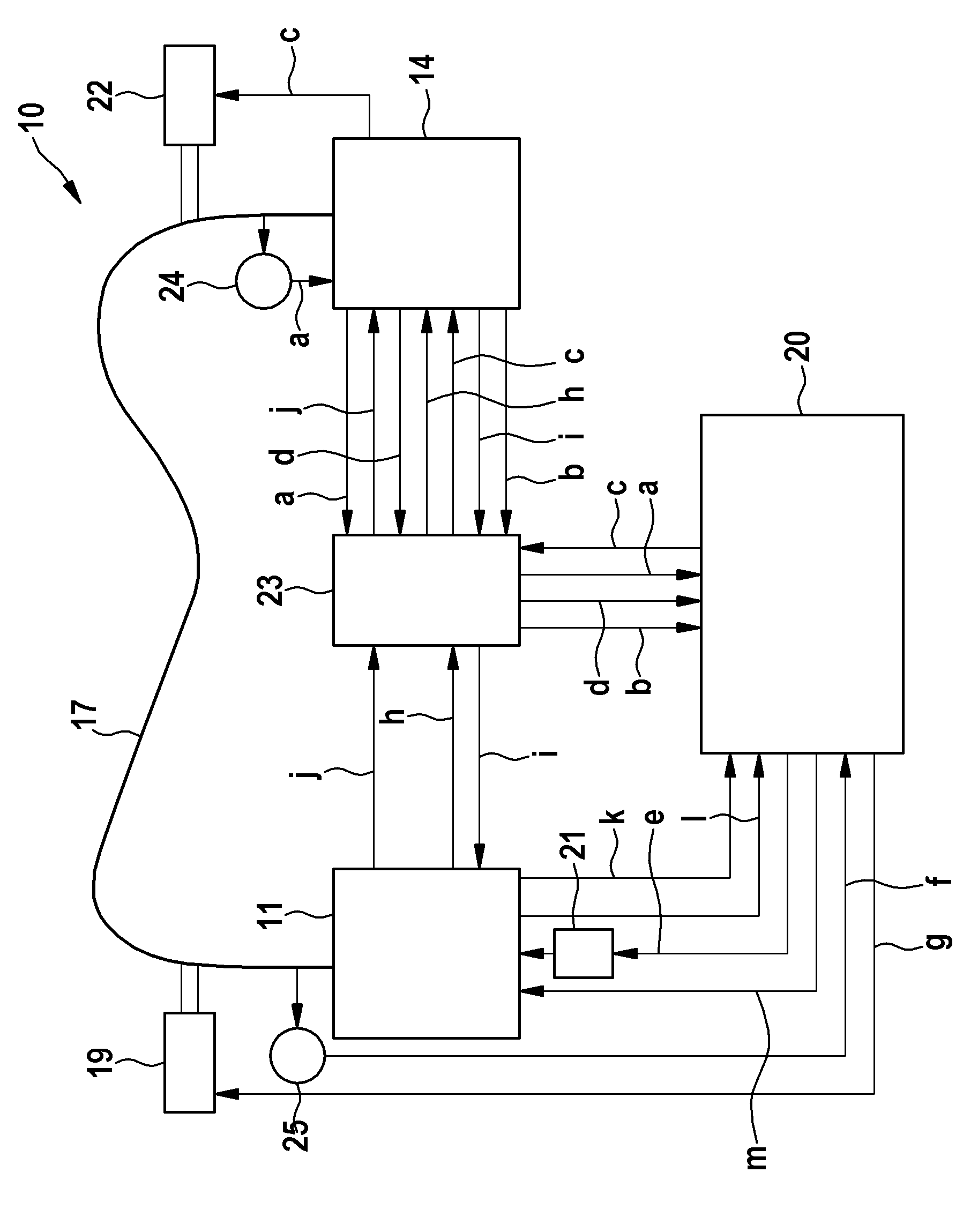

[0035] The invention is illustrated with the aid of a device for feeding filter rods from a filter rod production machine to a filter rod assembly machine. The invention of course also relates to all devices for sending (alternatively also described as transfer, launch, transport, etc.) rod-shaped products of the tobacco processing industry from a sending unit to a receiving unit, wherein the sending can be via a single line or via Several lines are completed, wherein in the latter case there is a corresponding number of transmitter modules and receiver modules.

[0036] The device 10 shown in the figure is constructed and arranged for the transfer of rod-shaped products for the tobacco processing industry and a sending unit 11 comprising at least one belt control mechanism 12 and at least one sending module 13 for sending the products along the transport direction T, At least one receiving unit 14 with a control mechanism 15 and at least one receiving module 16 for receiving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com