Variable-cross speed-change telescopic device for hygiene product water absorption body and variable-cross speed-change method

A technology for sanitary products and water-absorbing bodies, applied in applications, absorbent pads, clothing, etc., can solve problems such as uneven fit, sanitary products become horizontal, and sanitary products cannot be realized, and achieve perfect fit, improve quality, and reduce transportation. The effect of poor speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

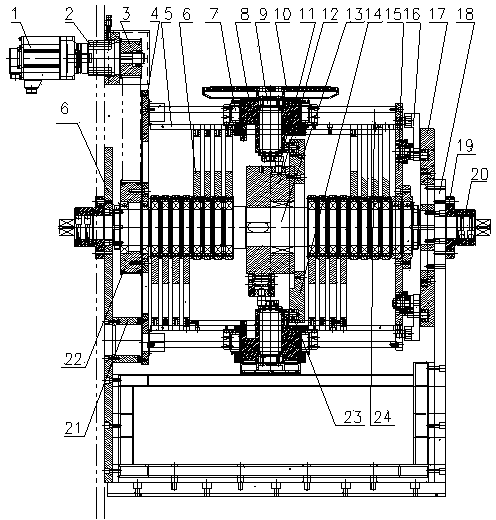

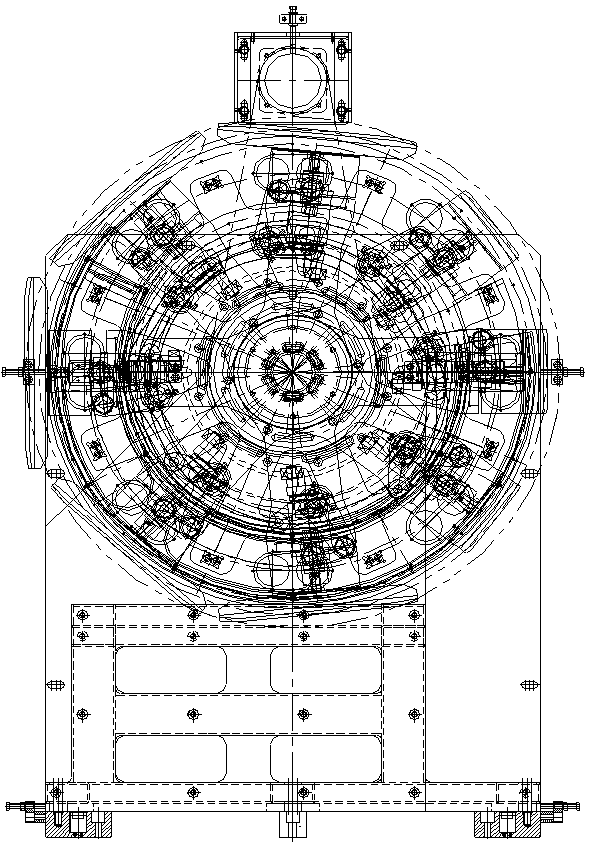

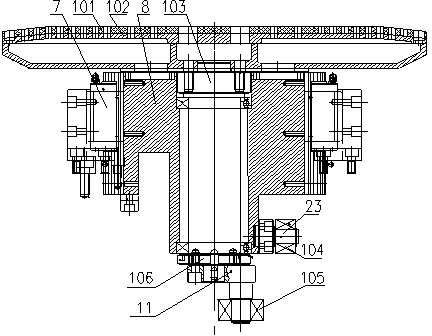

[0017] Embodiment 1: with reference to attached Figure 1-7 . A hygienic water-absorbing body variable lateral and variable speed telescopic device, the two ends of the main shaft 13 are fixed on the inner side wall board 6 and the outer side wall board 18, the speed changing end plate 17 is set on the main shaft 13 and the speed changing end plate 17 is fixed to the outer side wall board 18, The passive synchronous belt pulley 2 is set on the main shaft 13, the side of the passive synchronous belt pulley 2 is fixedly connected with the inner transmission plate 4 and drives the transmission plate 4 to rotate, the passive synchronous belt pulley 2 is driven by the active synchronous belt at the top of the inner wall panel 6 through the synchronous belt The wheel 3 is driven to rotate, the servo motor 1 drives the active synchronous belt wheel 3 to rotate through the reducer 2, the center wheel sheave cam 12 is set in the middle of the main shaft 13 through the bearing sleeve, a...

Embodiment 2

[0018] Embodiment 2: On the basis of Embodiment 1, a variable lateral and variable speed telescopic method of a hygienic absorbent body variable lateral and variable speed telescopic device, the servo motor 1 drives the active synchronous pulley 3 to rotate through the reducer 2, and the active synchronous pulley 3 Drive the passive synchronous pulley 2 to rotate through the synchronous belt, the passive synchronous pulley 2 drives the inner drive plate 4 to rotate, the inner drive plate 4 drives the outer drive plate 15 to rotate synchronously through eight uniformly distributed distance rods 24, and the outer drive plate 15 drives When the eight sets of four-link rocking wall mechanisms 16 rotate, the bearing parts of the bolt bearings 1613 in the eight sets of four-link rocking arm mechanisms 16 drive the eight shafts connected to the transverse small shaft 1602 under the action of the speed change guide grooves on the inner side of the transmission end plate 17. The bushing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com