Full-servo waist-forming variable-speed auto-fitting production line of pull-up baby diapers

A technology for baby pull-up pants and production lines, which is used in baby underwear, clothing, medical science, etc., can solve problems such as uneven fit, hygienic products become horizontal, and cannot realize hygienic products, and achieve perfect fit and reduce conveying speed. Poor, the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

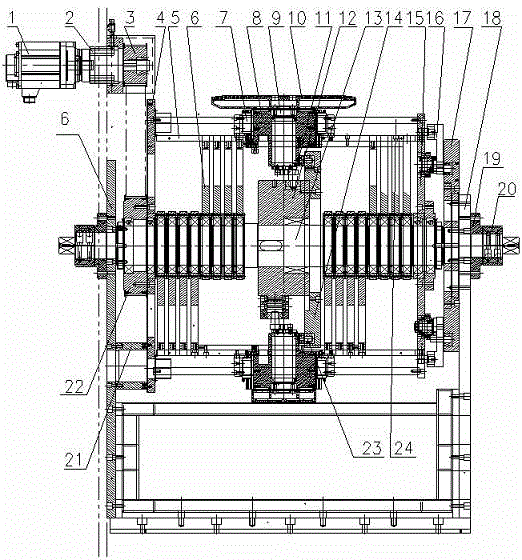

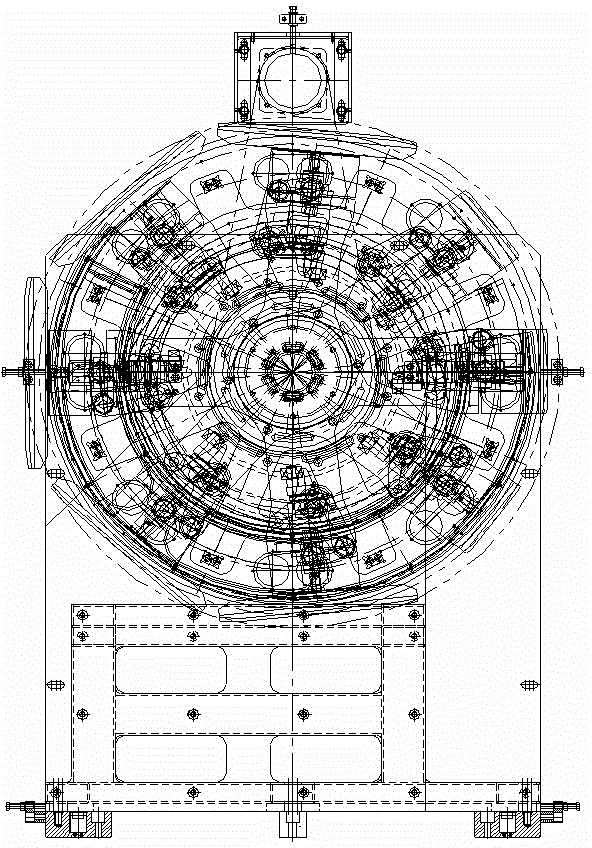

[0018] Embodiment 1: with reference to attached Figure 1-8 . A full servo variable horizontal and variable speed automatic laminating production line for baby pull-up pants, including a crushing device 201, a negative pressure suction device 202, a demoulding forming device 203, a polymer applying device 204, a water absorbing body variable lateral and variable speed stretching device 205, cotton Core cutting device 206, core cutting device 207, core turning device 208, elastic uncoiling device 209, dredging layer applying device 210, anti-side leakage vertical embossing device 211, trouser waist synthesis device 212, product half-folding device 213, discarding Sticker applying device 214, finished product cutting device 215, finished product folding device 216, waste rejecting device 217, elastic breaking device 218, color picture sticker applying device 219, stacker 220, in the water-absorbing body variable lateral variable speed telescopic device 205 The two ends of the m...

Embodiment 2

[0019] Embodiment 2: On the basis of Embodiment 1, a full servo variable horizontal and variable speed automatic lamination production line for baby pull-up pants, including a crushing device 201, a negative pressure suction device 202, a demoulding device 203, and a polymer applying device 204. Water-absorbing body variable lateral and variable speed telescopic device 205, cotton core cutting device 206, core body cutting device 207, core body steering device 208, elastic unwinding device 209, dredging layer applying device 210, anti-side leakage vertical embossing device 211 , trouser waist synthesis device 212, product half-folding device 213, discarding sticker applying device 214, finished product cutting device 215, finished product folding device 216, waste rejecting device 217, elastic breaking device 218, color picture sticker applying device 219, stacker 220 , the servo motor 1 in the water-absorbing body variable lateral variable speed telescopic device 205 drives th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com