Full-automatic screw length automatic detecting and sorting apparatus

An automatic detection and sorting device technology, applied in sorting and other directions, can solve the problems of low detection efficiency and unintuitive detection results, and achieve the effects of high degree of automation, intuitive screw length detection, and reduced manual maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

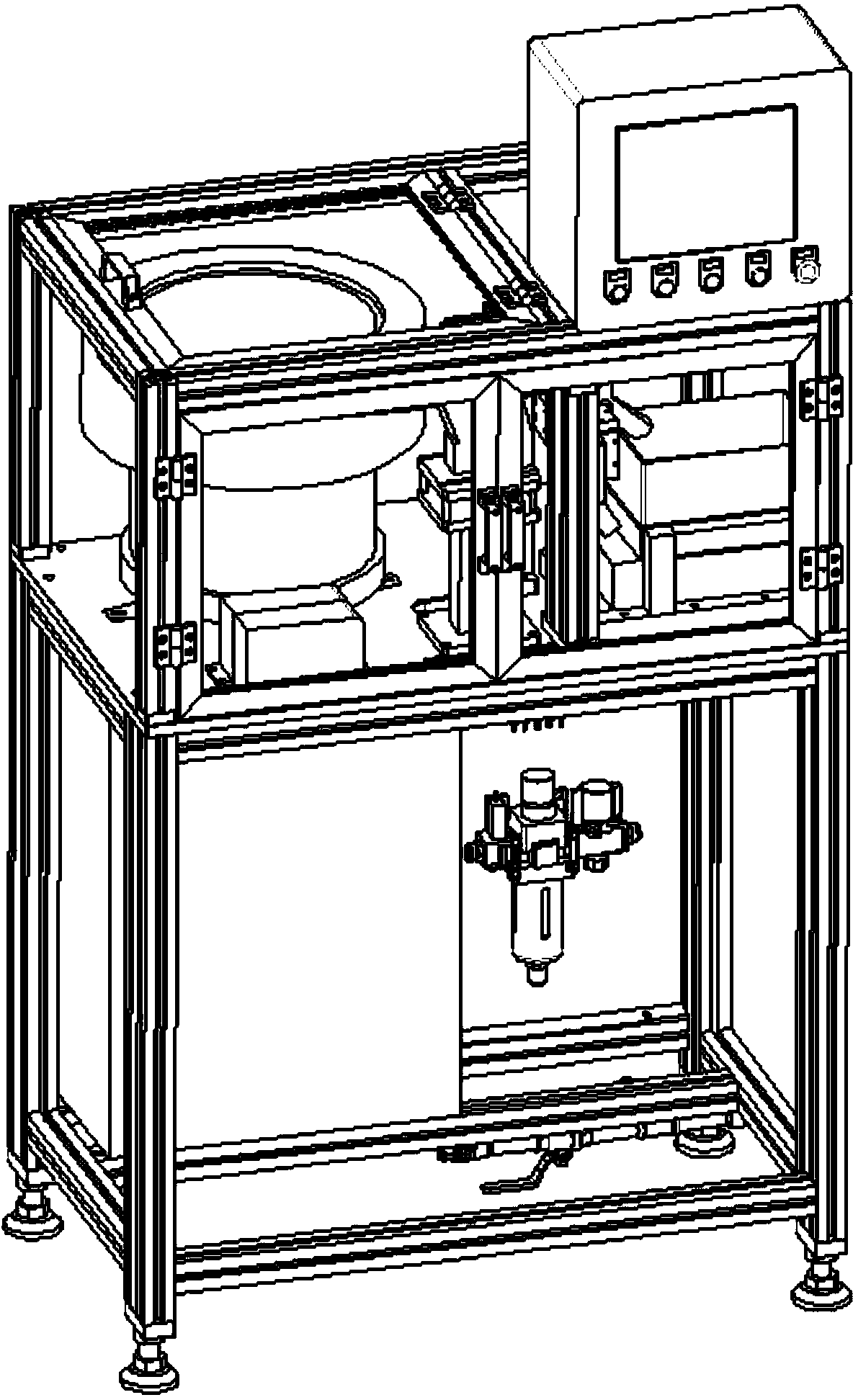

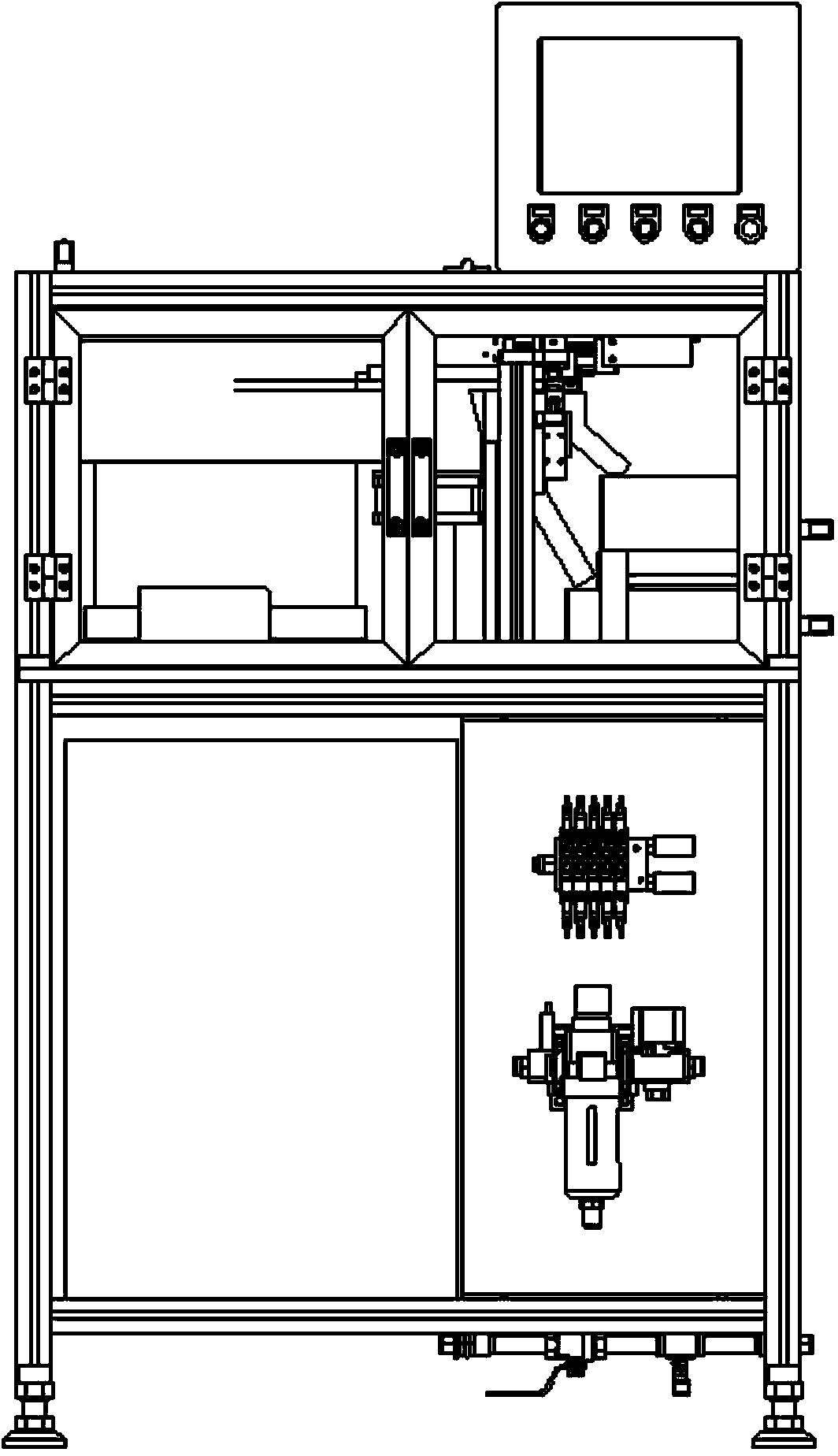

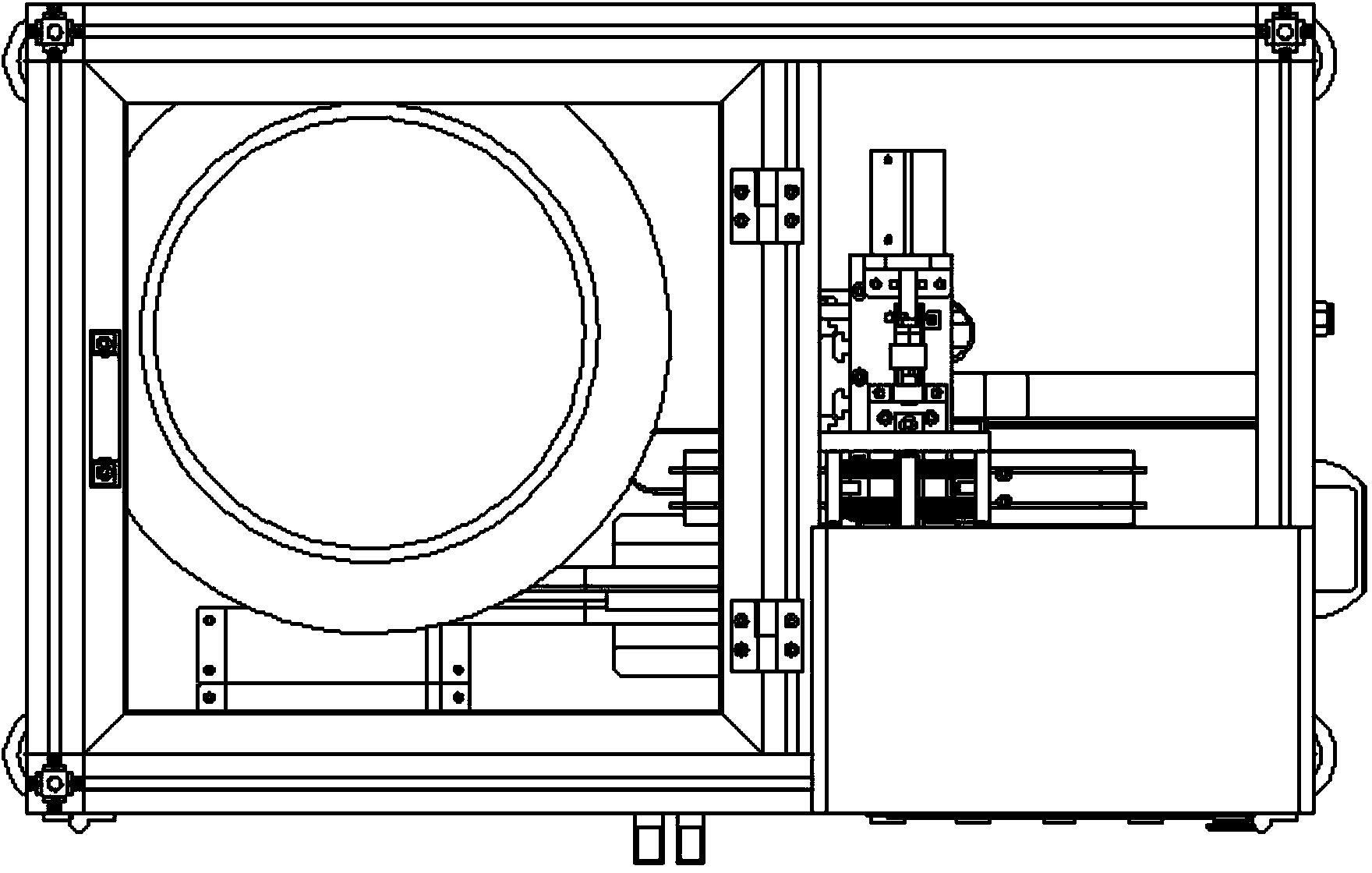

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0023] see Figure 1-5 , a fully automatic screw length automatic detection and sorting device, including an automatic feeding mechanism 1, a conveying guide rail is provided in the automatic feeding mechanism, and the screw moves along the conveying guide rail in a vertical state, and the moving direction of the conveying guide rail is X direction, the direction horizontal and vertical to the X direction is the Y direction; the end of the conveying guide rail is a screw length detection station, and a compression cylinder 2 is arranged above it, and the compression cylinder 2 compresses the screw from top to bottom; A detection cylinder is arranged below the screw length detection station, and the detection cylinder drives the displacement sensor 3 to move upward until it touches the screw to be detected; above the station to be detected, a re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com