Auxiliary centering fixture

A tooling and relative positioning technology, which is applied in the field of mechanical parts processing, can solve the problems of cumbersome operation and low precision, and achieve the effects of improving processing efficiency, improving centering accuracy, and simplifying centering operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

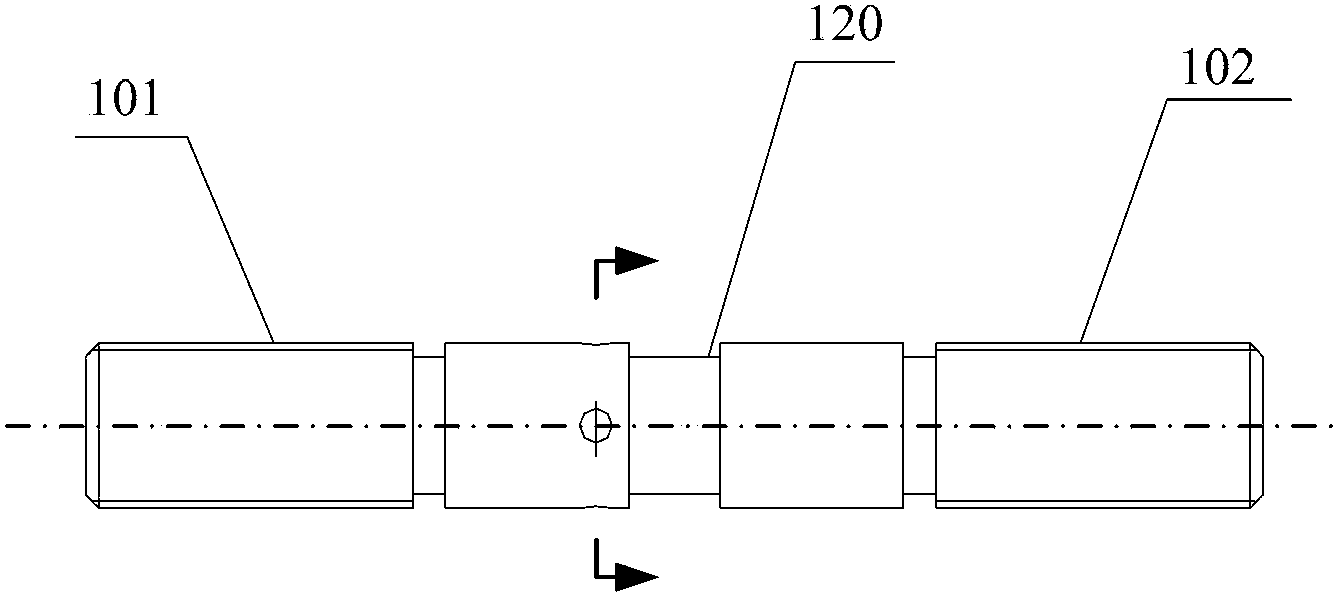

[0014] The "axial direction" mentioned in the present invention refers to the straight line direction where the central axis of the cylindrical rod is located, and the "circumferential direction" refers to the circle formed around the central axis of the cylindrical rod in the plane perpendicular to the "axial direction". Circumferential direction of the ring.

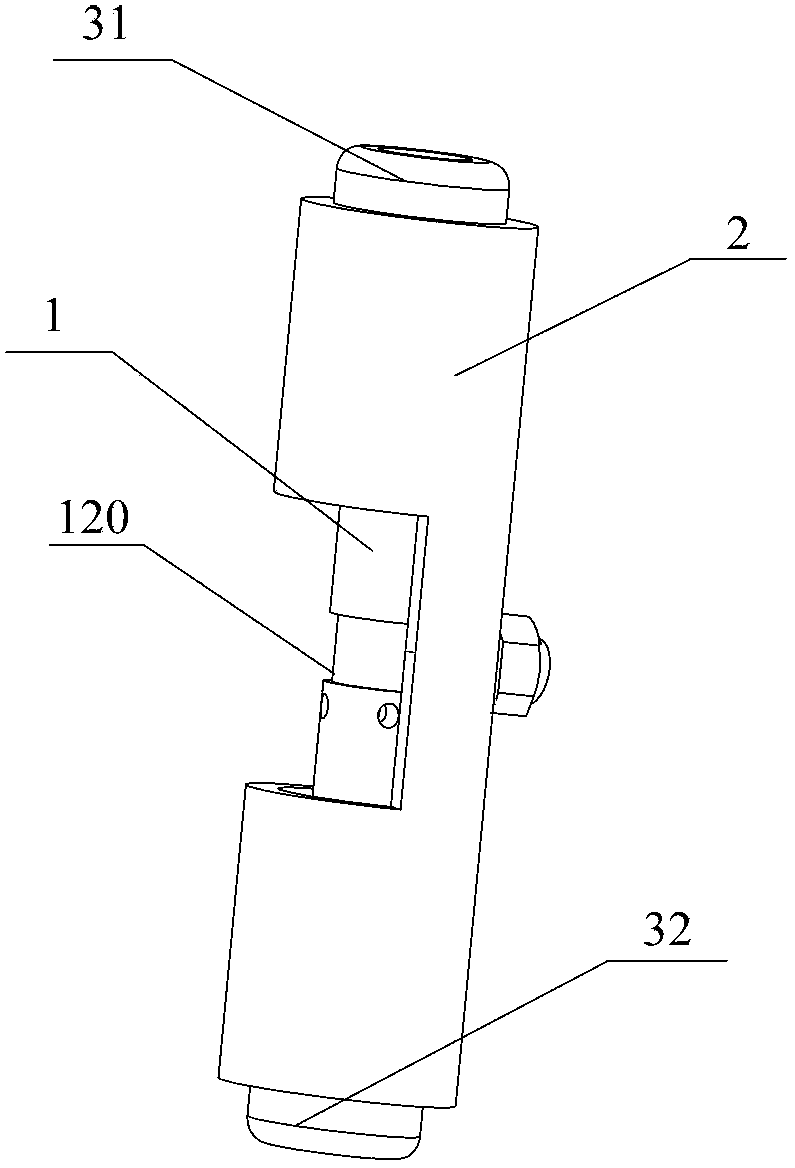

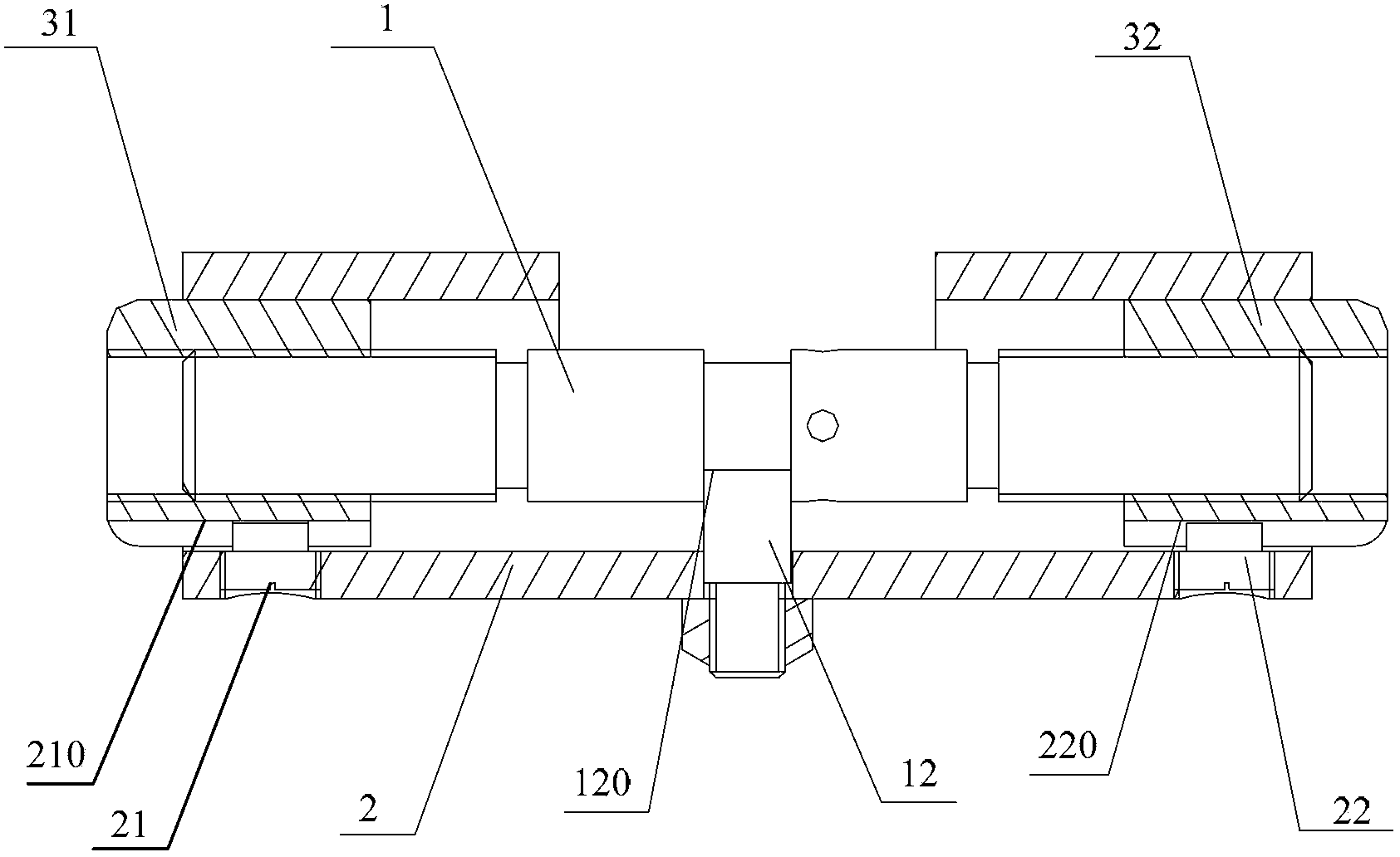

[0015] figure 1 It is a perspective view of an embodiment of the auxiliary centering tool of the present invention; figure 2 for figure 1 sectional view of image 3 for figure 1 Schematic diagram of the structure of the column rod; please refer to Figure 1-3 , this embodiment provides an auxiliary centering tool, including: a columnar rod 1 and a guide sleeve 2 sleeved outside the columnar rod, the guide sleeve 2 is connected to the columnar rod through a positioning piece 12, and the positioning piece 12 can make The cylindrical rod 1 and the guide sleeve 2 are positioned relative to each other in the axial dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com