Pinching Expansion Bolt

A technology of expansion bolts and expansion tubes, which is applied in the field of special fixed connectors, can solve problems such as tail shrinkage, unstable seams of bent expansion tubes, and failure to achieve expansion effects, and achieve the effect of not being easy to slip out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

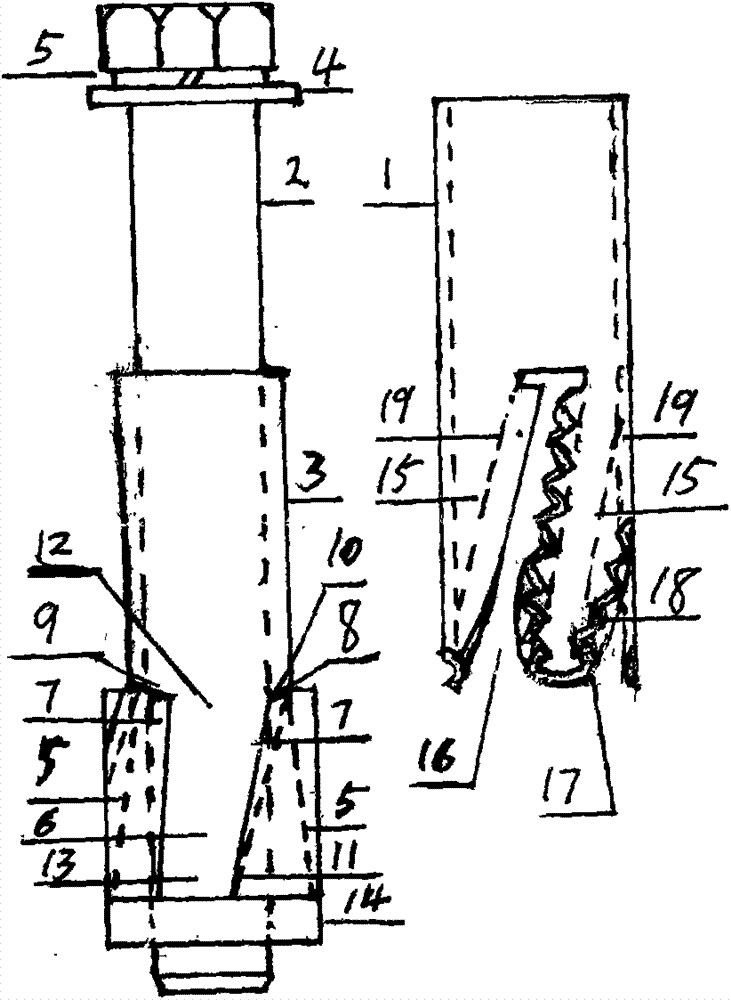

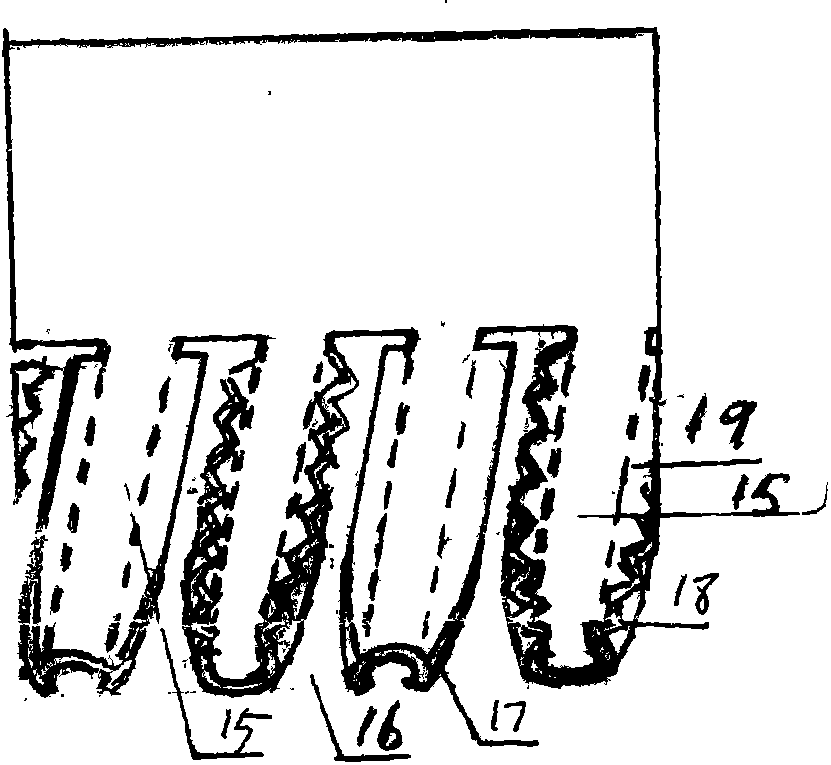

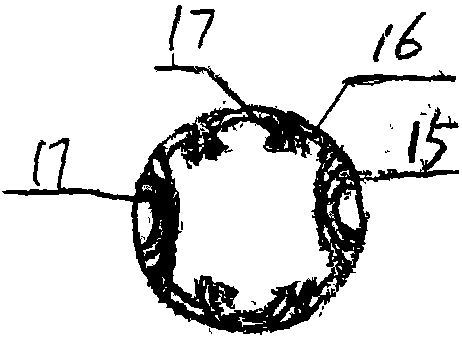

[0016] The clamp expansion bolt is composed of expansion tube (1), screw rod (2), nut (3), washer (4), spring washer (20), etc., and a cone (5) or screw rod is arranged at one end of the nut (3) (2) One end is provided with a cone (5). The cone (5) is provided with a spiral buttress (6), and both sides of the spiral buttress (6) are provided with a spiral buttress (7), and the wall of the spiral buttress (7) is an acute angle (8) or an arc surface (9), the small diameter end of the cone (5) is provided with a high wall (10), and the high wall (10) gradually advances to a shallow wall (11) at the large diameter end. A wide clamping channel (12) is set at the inlet end of the spiral clamping channel (6), and the wide clamping channel (12) gradually advances to the large diameter end to set a narrow clamping channel (13). The large-diameter end of the cone (5) is provided with a cylinder (14). Set the spiral clip (15) on the expansion tube (1), the width of the spiral clip (15)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com