Electric connector

A technology of electrical connectors and connectors, which is applied in the direction of connections, circuits, parts of connection devices, etc., can solve problems such as inability to cope, and achieve the effect of increasing the installation strength and expanding the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

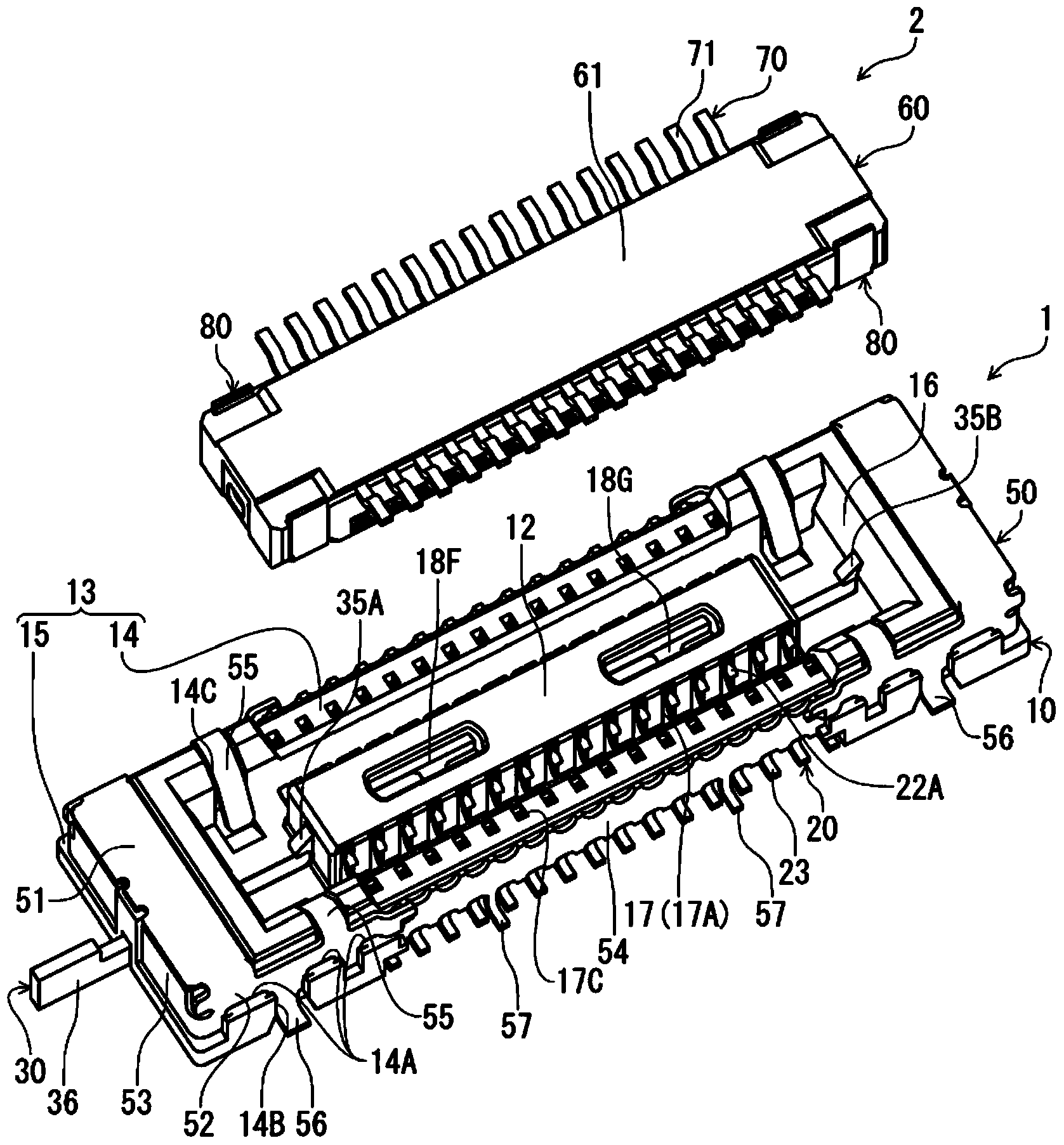

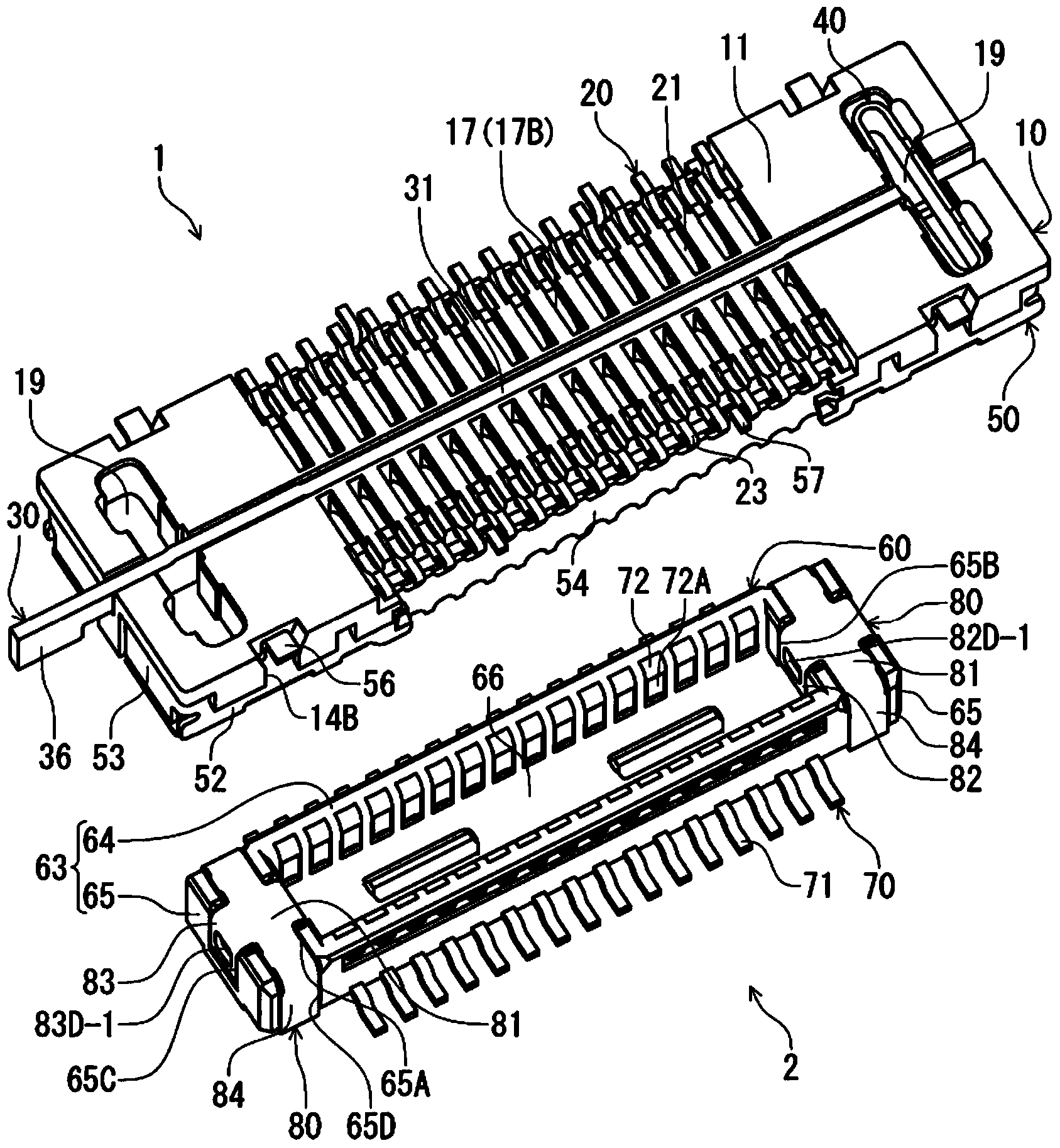

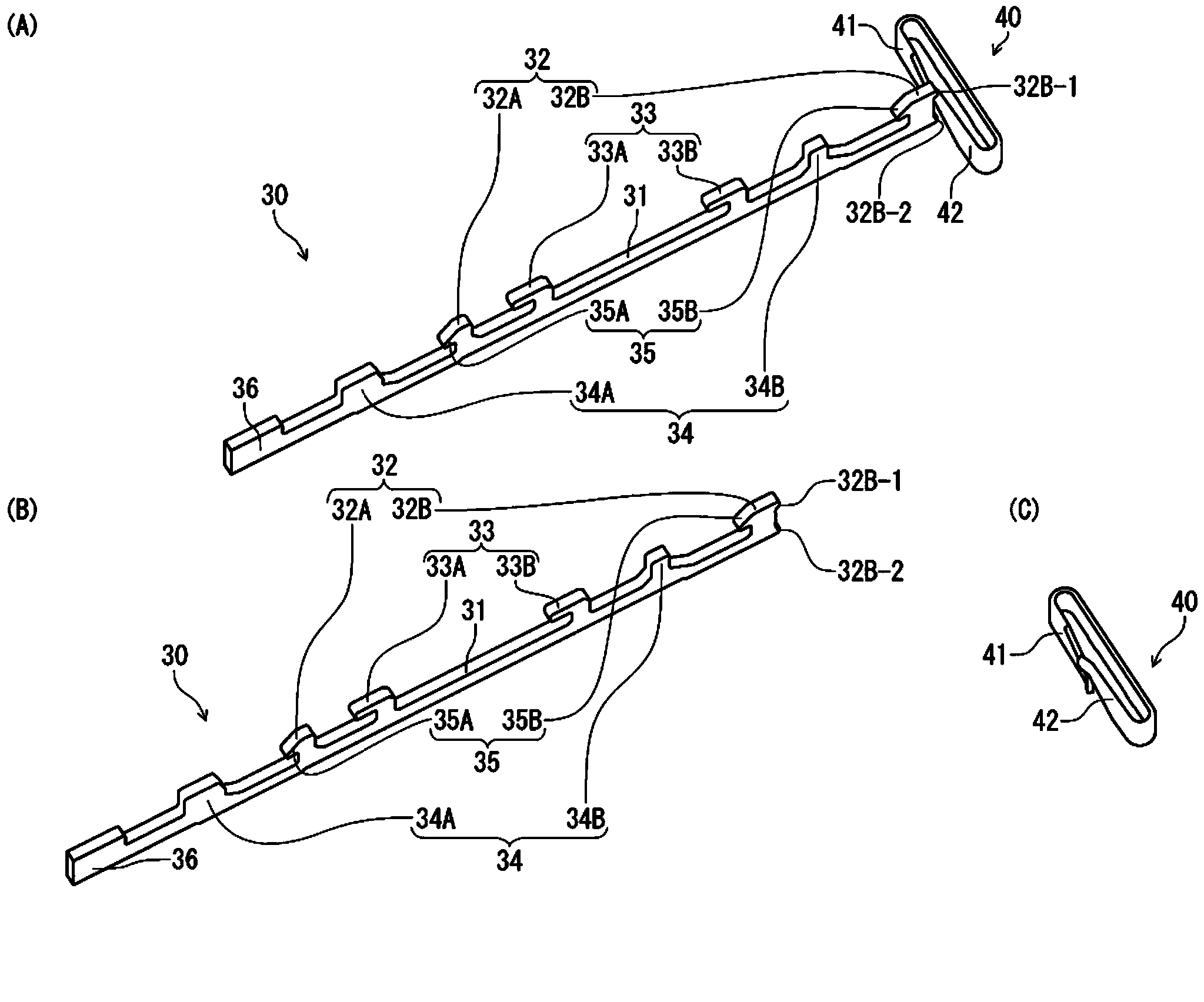

[0030] figure 1 It is a perspective view of the receptacle connector 1 according to this embodiment and the plug connector 2 fitted to the receptacle connector 1 from above, showing a state before the connectors are fitted. figure 2 will be figure 1 The perspective view in which the receptacle connector 1 and the plug connector 2 are turned upside down is shown, and is a perspective view shown in a posture where the plug connector 2 is fitted from below.

[0031] The plug connector 2 according to this embodiment and the receptacle connector 1 as a mating connector of the plug connector 2 are respectively arranged on the mounting surfaces of different circuit boards (not shown) for electrical connection to circuit boards. device, constitutes a direction at right angles with respect to the face of each circuit board ( figure 1 The up and down direction in the middle) is the connector assembly in the plugging and unplugging direction. In this embodiment, the fitting direction...

no. 2 approach >

[0097] In the first embodiment, the locked portions 82D-1, 83D-1 of the locking metal piece 80 of the plug connector 2 are provided on the edges of the hole portions 82D, 83D of the locked leg portions 82, 83, but in the second The embodiment differs from the first embodiment in that the locked portion is formed as a protrusion protruding from the plate surface of the locked leg. Figure 9 It is an enlarged cross-sectional view showing a part of the receptacle connector and the plug connector according to the second embodiment, and shows the terminals arranged on one end side of the terminal arrangement direction by using a cross section on a plane perpendicular to the width direction of the connector. The locking state of the locking metal piece of the plug connector and the matching locking metal piece of the socket connector. The shape of the plug connector 102 of the second embodiment is the same as that of the plug connector 2 of the first embodiment except for the above-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com