Electric drive system for new energy vehicles

An electric drive system, new energy vehicle technology, applied in control systems, AC motor control, electrical components, etc., can solve the problems of short-circuit damage to Y capacitors, inability to stop the motor, and no protection measures for Y capacitors, so as to avoid burnout , reduce destructive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

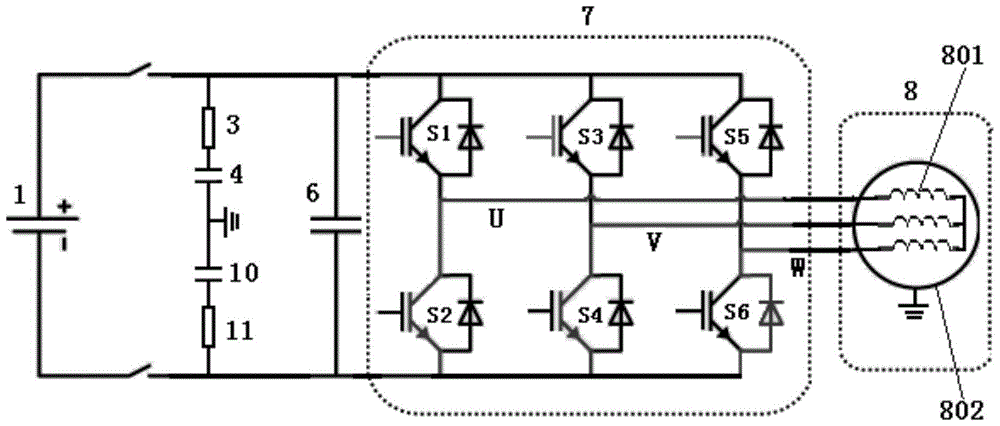

[0025] Electric drive systems for new energy vehicles, such as figure 1 As shown, it includes a high-voltage power battery 1, a DC support capacitor 6, a first Y capacitor 4, a second Y capacitor 10, a first capacitor protection device 3, a second capacitor protection device 11, a motor controller (inverter) 7, Three-phase AC motor 8;

[0026] The DC support capacitor 6 is connected in parallel at both ends of the positive pole and the negative pole of the high-voltage power battery 1;

[0027] In the motor controller 7, two input terminals are connected in parallel to both ends of the DC support capacitor 6, and three output terminals UVW are respectively connected to the three-phase input lines of the three-phase AC motor 8;

[0028] The three-phase AC motor 8, the casing 802 is directly connected to the ground of the vehicle body or indirectly connected to the ground of the vehicle body through other intermediate media;

[0029] The first Y capacitor 4 and the first capac...

Embodiment 2

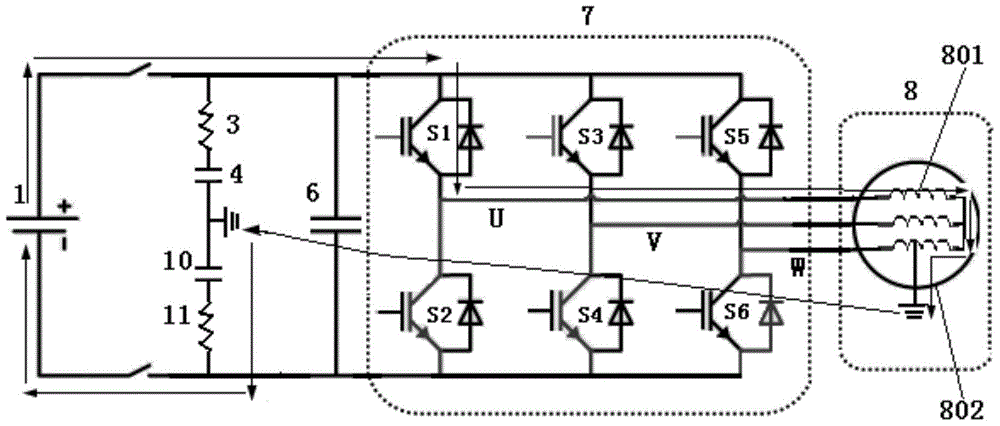

[0036] Based on the electric drive system for new energy vehicles in Embodiment 1, such as figure 2 As shown, the first capacitive protection device 3 and the second capacitive protection device 11 are resistors with variable resistance properties such as positive temperature coefficient thermistors (PTC);

[0037] For the positive temperature coefficient thermistor, when the temperature is lower than a certain value, its resistance value is small and changes little, and when the temperature rises to a certain value, its resistance value increases rapidly.

[0038]Taking the motor W-phase winding short circuit to ground as an example, when the electric drive system is in the running mode, when the W in the three-phase AC motor three-phase winding 801 is short-circuited to the three-phase AC motor casing 802 or the insulation fails, due to the upper system ( Such as the battery management system) and the motor controller 7 failed to detect the fault, so the six insulated gate ...

Embodiment 3

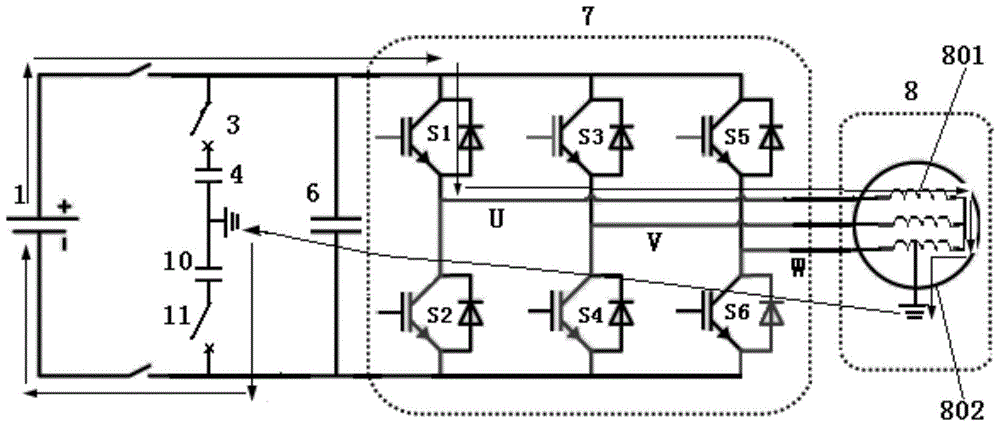

[0040] Based on the electric drive system for new energy vehicles in Embodiment 1, such as image 3 As shown, the first capacitive protection device 3 and the second capacitive protection device 11 are switching components such as a circuit breaker with an overcurrent disconnection function; the circuit breaker, when the current flowing through it is less than or equal to the set value, It is in the normally closed state; when the current flowing through it is greater than the set value, it will be automatically disconnected; the circuit breaker can be restored to the normal normally closed state through manual or electric control, and then returned to the normal normally closed state.

[0041] image 3 In the electric drive system for new energy vehicles shown, the first circuit breaker 3 is connected in series with the first Y capacitor 4 to form a group, which is connected between the positive pole of the high-voltage power battery 1 and the ground of the vehicle body; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com