A kind of preparation method of polyamide composite nanofiltration membrane whose main chain contains ether oxygen structure

A composite nanofiltration membrane and polyamide technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of poor hydrophilicity, poor pollution resistance and pure water permeation flux of nanofiltration membranes Low-level problems, to achieve the effect of high permeation flux of pure water, good hydrophilicity, and low molecular weight cut-off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

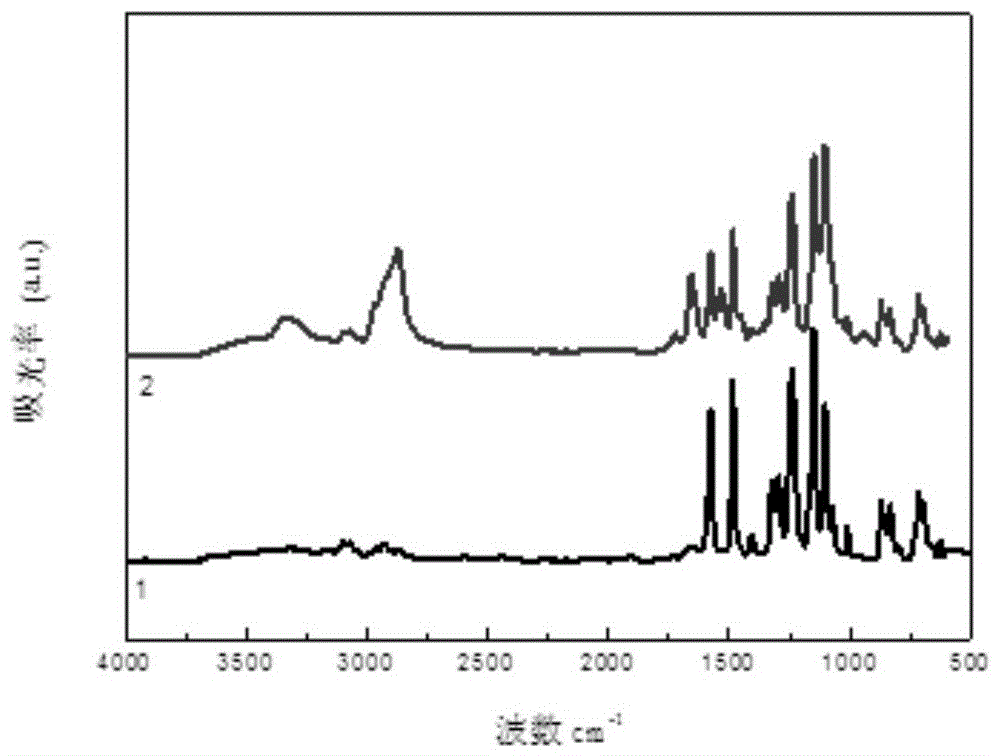

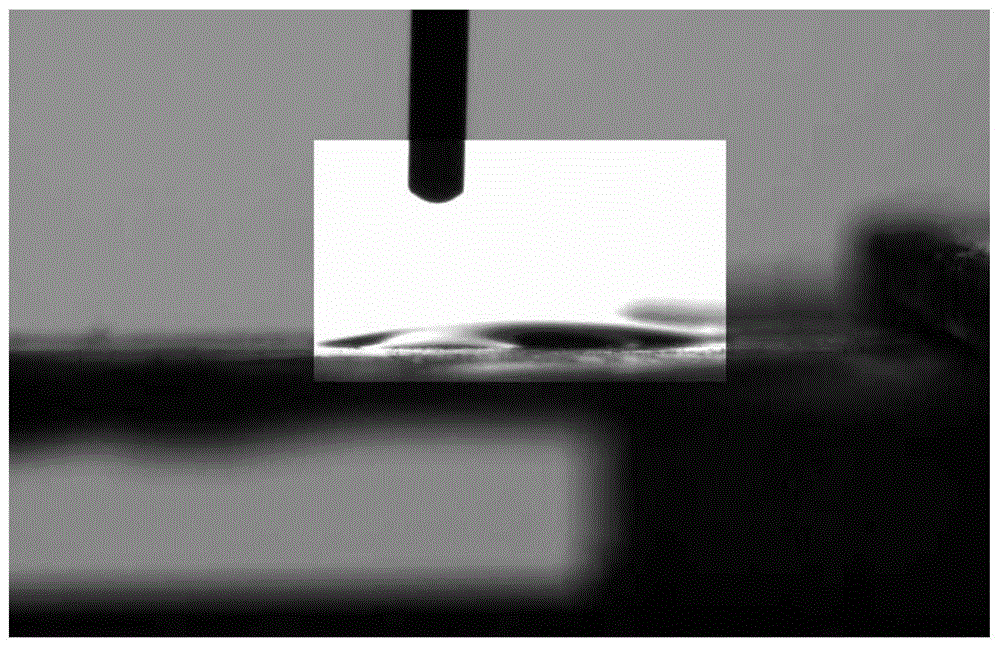

[0016] Specific embodiment one: the preparation method of the polyamide composite nanofiltration membrane of a kind of main chain containing ether oxygen structure of the present embodiment is to carry out according to the following steps:

[0017] 1. Prepare the polymer ultrafiltration base membrane with the phase inversion method of the hollow fiber base membrane, and then remove the surface moisture of the polymer ultrafiltration base membrane to obtain a polymer ultrafiltration base membrane with no moisture on the surface;

[0018] 2. Configure an amino-terminated polyethylene oxide solution with a concentration of 0.05wt% to 10.0wt%;

[0019] 3. Use the amino-terminated polyethylene oxide solution configured in step 2 to soak the surface-free polymer ultrafiltration base membrane obtained in step 1 for 30s to 30 minutes, and dry in the shade after soaking to obtain a dry ultrafiltration base membrane;

[0020] 4. Dissolving the polyacyl chloride in an organic solvent, an...

specific Embodiment approach 2

[0024] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the hollow fiber base membrane described in step 1 is PEI (polyetherimide), PS (polysulfone), PES (polyethersulfone), PAN (polyacrylonitrile), PVDF (polytetrafluoroethylene) or PP (polypropylene). Others are the same as in the first embodiment.

specific Embodiment approach 3

[0025] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: in Step 2, the solution of amino-terminated polyethylene oxide with a concentration of 0.5 wt% to 10.0 wt% is prepared. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com