Method for preparing hollow fiber type forward osmotic membrane

A forward osmosis membrane, hollow technology, applied in the field of preparation of hollow fiber forward osmosis membrane, can solve the problems of unsatisfactory application, difficult membrane cleaning, small specific surface area, etc., and achieve anti-pollution cleaning, easy cleaning, and large filtration area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0028] A preparation method of hollow fiber type composite forward osmosis membrane specifically includes the following steps:

[0029] 1. Take a certain amount of PEI hollow fiber porous base membrane into a membrane module, and place the membrane module in the membrane filtration device;

[0030] 2. Wash the residual glycerin on the surface of the membrane module with distilled water, remove the residual moisture from the membrane module with an air compressor, and dry the hollow fiber base membrane in the shade;

[0031] 3. Prepare a polyamine aqueous solution, make the polyamine aqueous solution pass through the inner surface of the membrane module, and then use an air compressor to remove excess water on the membrane module surface. The polyamine is m-phenylenediamine with a concentration of 2.0% by weight, and the passage time of the polyamine aqueous solution is 120 seconds.

[0032] 4. Prepare an organic solution containing polybasic acid chloride, make the organic solution pa...

example 2- Embodiment 10

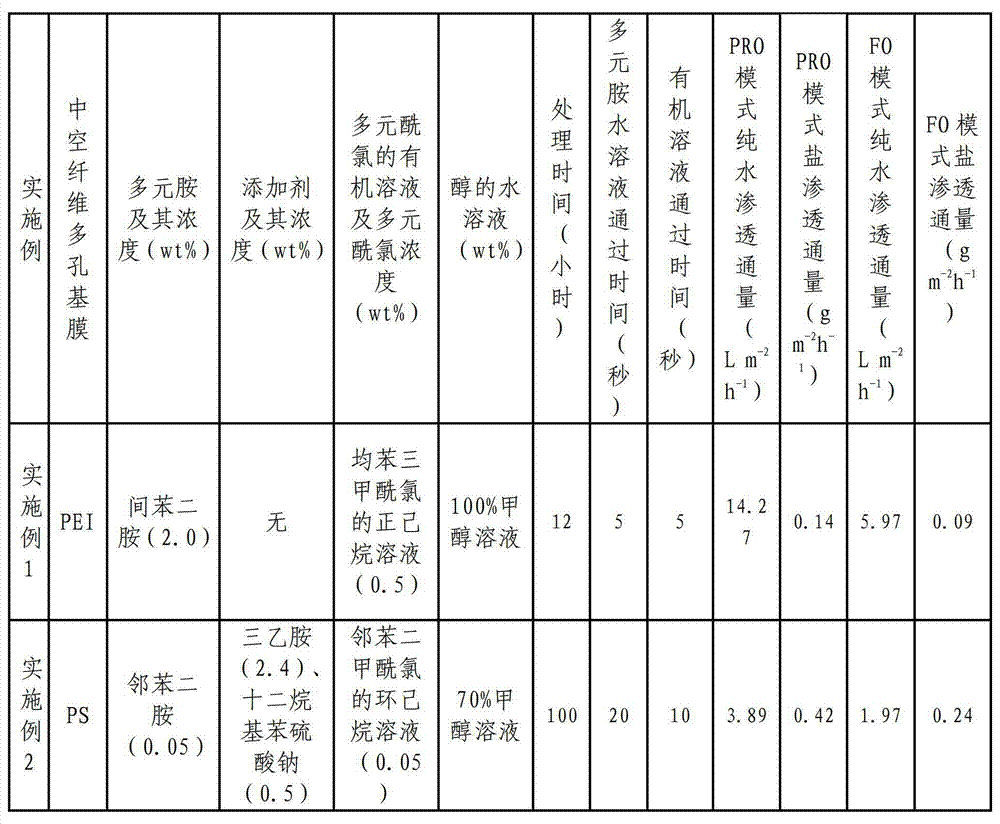

[0036] The hollow fiber type composite forward osmosis membrane was prepared using the same process as in Example 1, and tested. The difference lies in the use of different hollow fiber porous base membranes listed in Table 1, polyamines and their concentrations, additives and their concentrations, polyacid chloride organic solutions and polyacid chloride concentrations, alcohol aqueous solutions, passage time, treatment time. The test results of the prepared film are also shown in Table 1.

[0037] Table 1

[0038]

[0039]

[0040]

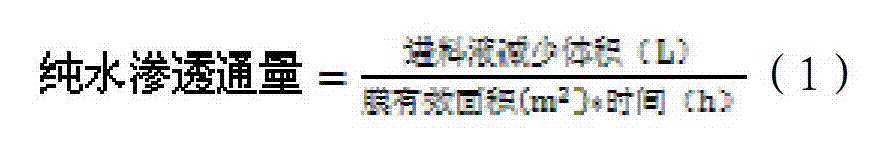

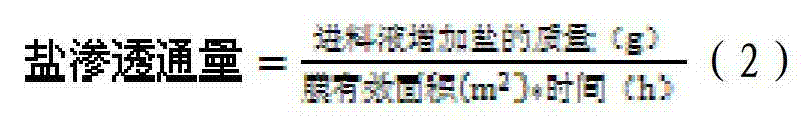

[0041] It can be seen from Table 1 that the hollow fiber composite forward osmosis membrane prepared by the method of the present invention has high pure water permeation flux and low salt permeation flux, combining the definition and formula of pure water permeation flux and salt permeation flux ( 1) (2) It can be inferred, the effective filtration area of the same size components is large, which is suitable for the forward osmosis separation pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com