Automatic cap-closing mechanism of bottle cap injection molding mold

An injection mold, automatic technology, applied in the field of automatic capping mechanism, can solve the problems of slow speed, low efficiency and high labor intensity, and achieve the effects of reliable fixing, convenient installation and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

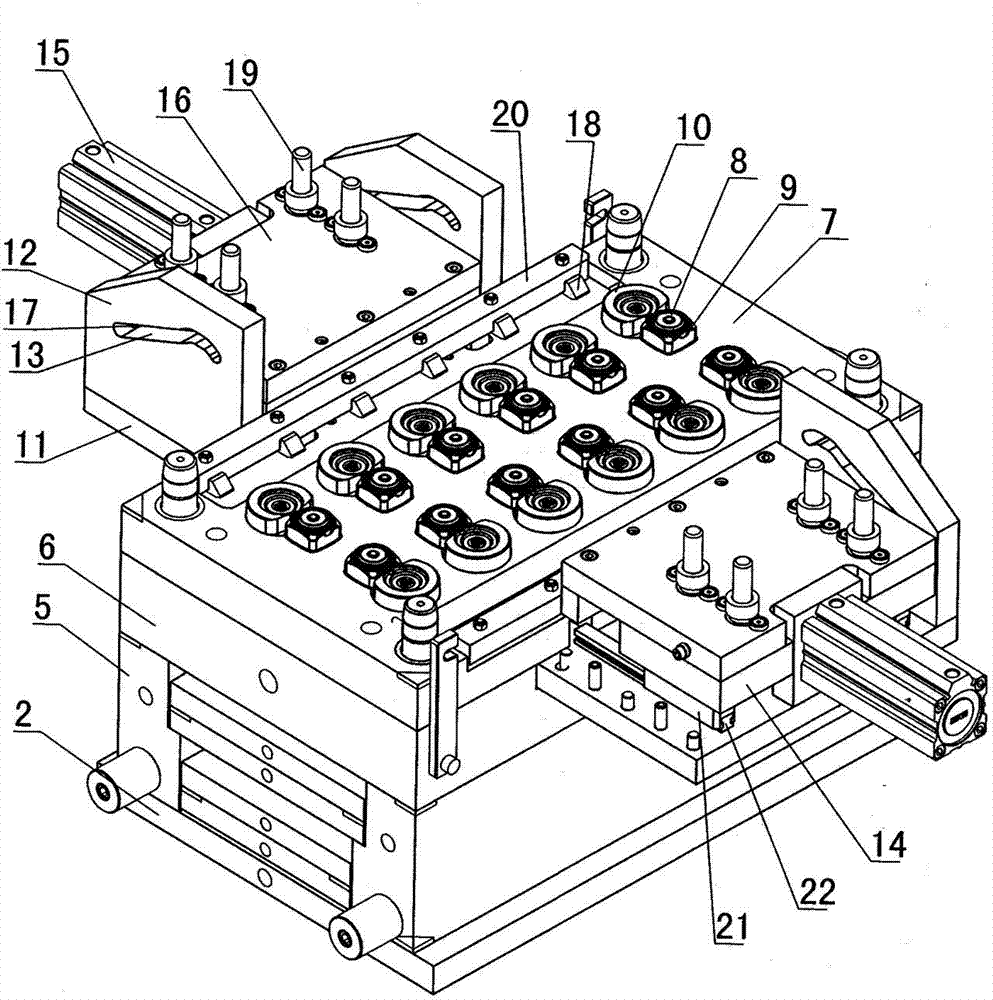

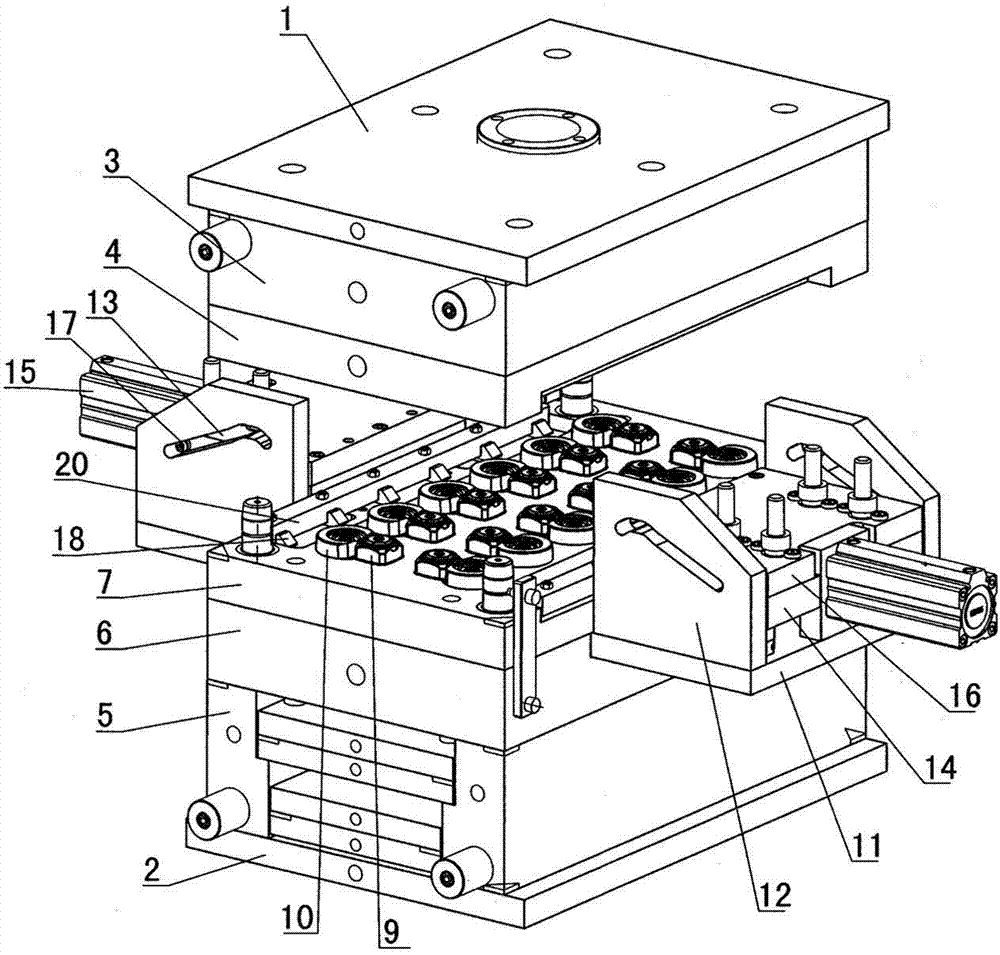

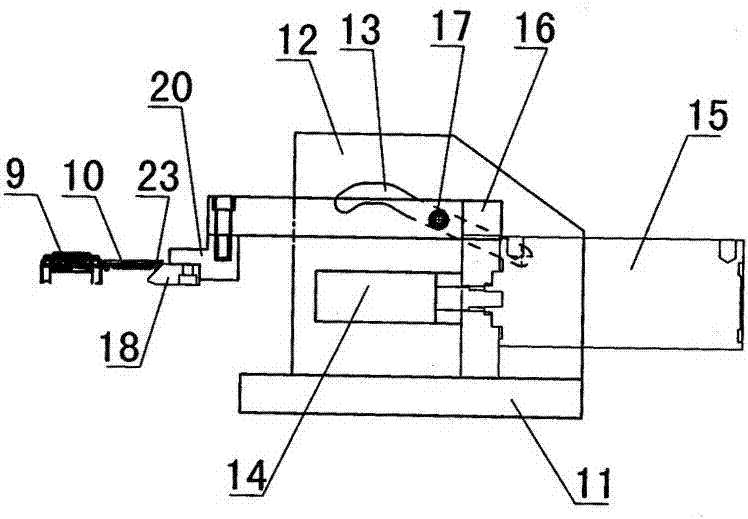

[0012] The invention relates to an automatic cap closing mechanism of a bottle cap injection mold, such as figure 1 — Figure 5 As shown, it includes the upper mold plate 1 and the lower mold plate 2, the fixed mold fixed plate 3 is installed under the upper mold plate, the fixed mold plate 4 is installed under the fixed mold fixed plate, two mold feet 5 are installed on the lower mold plate, and the ejector is set between the two mold feet Mechanism, the movable mold fixed plate 6 is installed on the two mold feet, the movable template 7 is installed on the movable mold fixed plate, the movable mold insert 8 is installed in the movable mold, the gap between the movable mold insert 8, the movable template 7 and the fixed template 4 A mold cavity is formed, and there is an integrally injection-molded bottle cap seat 9 and cover plate 10 in the mold cavity. An automatic lid closing mechanism is provided on one side of the movable template, and the automatic lid closing mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com