Fuzzy Control Method for Aluminum Electrolysis

A technology of fuzzy control and aluminum electrolysis, applied in the field of aluminum electrolytic cells, can solve the problems of large temperature deviation of the primary crystal, high equipment requirements, and inaccurate partitioning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in combination with embodiments.

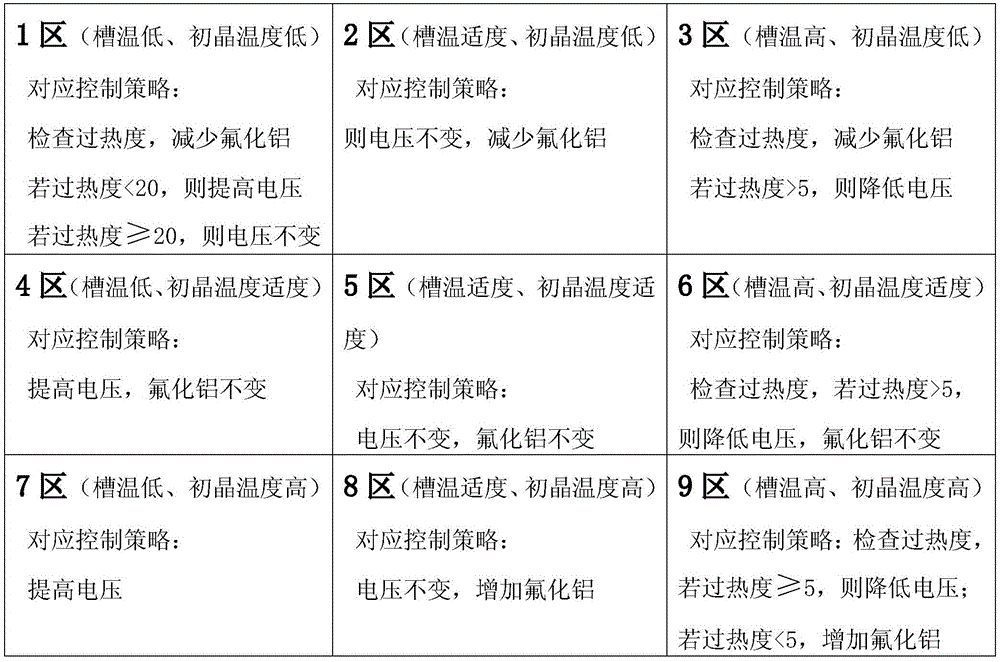

[0028] Taking an aluminum electrolytic cell (200KA) in a certain workshop as an example, the fuzzy control method for aluminum electrolysis of the electrolytic cell includes the following steps:

[0029] Step 1. Carry out temperature classification of aluminum electrolyte

[0030] The temperature control center value of the measured electrolytic cell is 950°C. The temperature of the aluminum electrolyte is set as the second level between 900°C and 950°C. for 3 poles.

[0031] Step 2: Grading the primary crystal temperature

[0032] The primary crystal temperature is described by the change trend of aluminum electrolyte temperature, molecular ratio, voltage, and feeding amount. First, determine the change trend of aluminum electrolyte temperature. The change trend of aluminum electrolyte temperature is expressed by weighted moving average method. The change trend is set to A, A=(W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com